Partition-type buffer structure at the exit of railway tunnel

A cushioning structure and clapboard-type technology, which is applied in tunnels, mining equipment, earthwork drilling and mining, etc., can solve the problems of difficult tunnel opening buffer structure transformation, inability to build structural buffer structures, and uneconomical problems, so as to alleviate the micro pressure wave at the entrance of the tunnel Effect, maximization of economic benefits, effect of reducing pressure peaks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

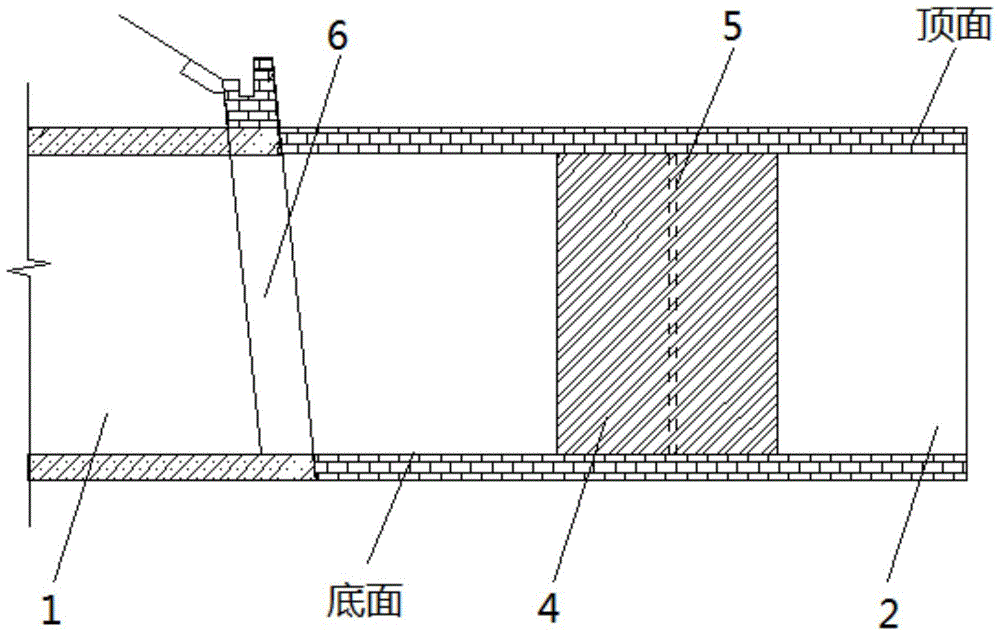

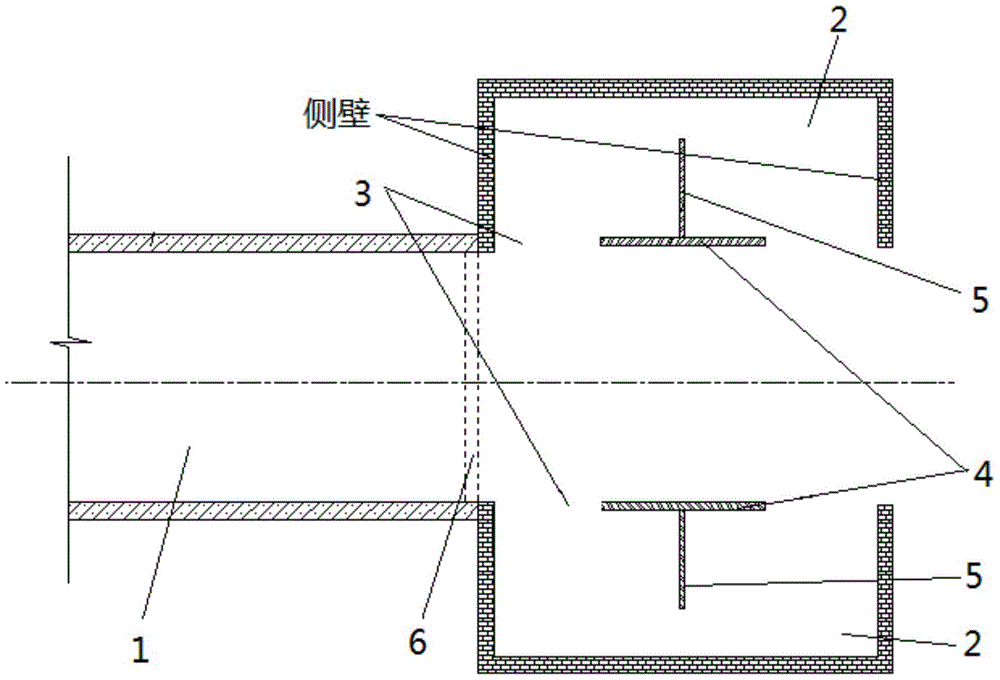

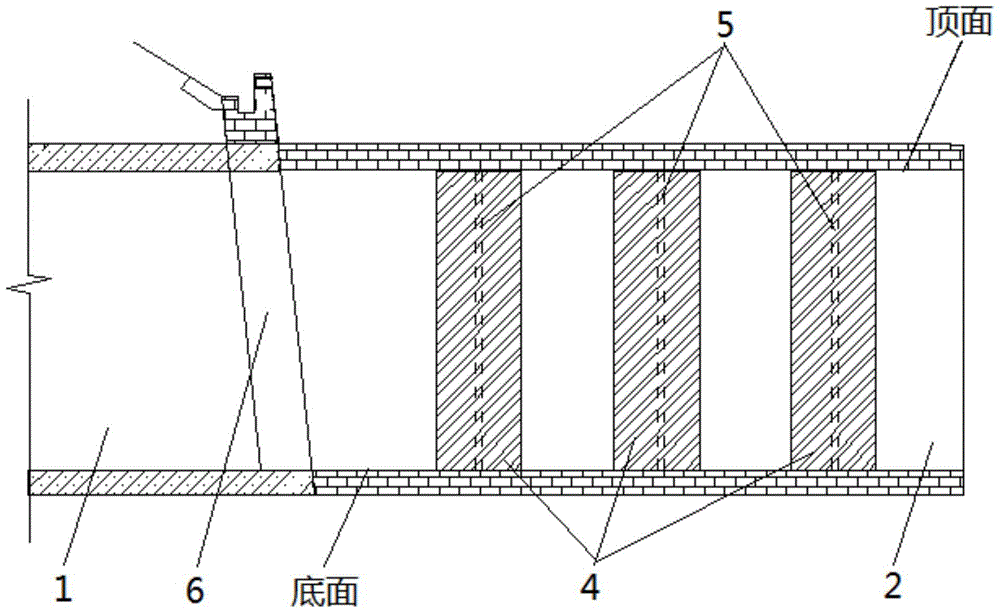

[0026] like figure 1 and figure 2 As shown, in the railway tunnel outlet partition plate type buffer structure designed by the present invention, a type box 2 is respectively arranged on both sides of the tunnel exit 6, and the side wall of the type box 2 close to the center line of the tunnel 1 is an opening surface 3; The box 2 is provided with a first partition 4 parallel to the opening surface 3, the two ends of the first partition 4 are fixedly connected to the top surface and the bottom surface of the mold box 2, and the same mold box 2 The sum of the areas of the first partition 4 is less than the area of the opening surface 3 of the mold box 2; and the second partition 5 connected with the first partition 4, the second partition 5 stretches into the mold box 2 . The area mentioned here means that the first separator 4 is regarded as a surface with a thickness of 0, just like the opening surface 3 . Preferably, the area of the first partition 4 at the same mold ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com