High-speed railway tunnel structure

A tunnel structure, high-speed railway technology, applied in tunnels, mining equipment, earthwork drilling and mining, etc., can solve the micro-pressure wave effect at the entrance of the tunnel, the air resistance of the aerodynamic load locomotive, the inability to comprehensively alleviate the aerodynamic effect, and the inability to open the tunnel Set buffer structure and other issues to achieve the effects of alleviating the micro-pressure wave effect at the opening, alleviating the aerodynamic effect, and alleviating the negative pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Further illustrate the present invention below in conjunction with accompanying drawing:

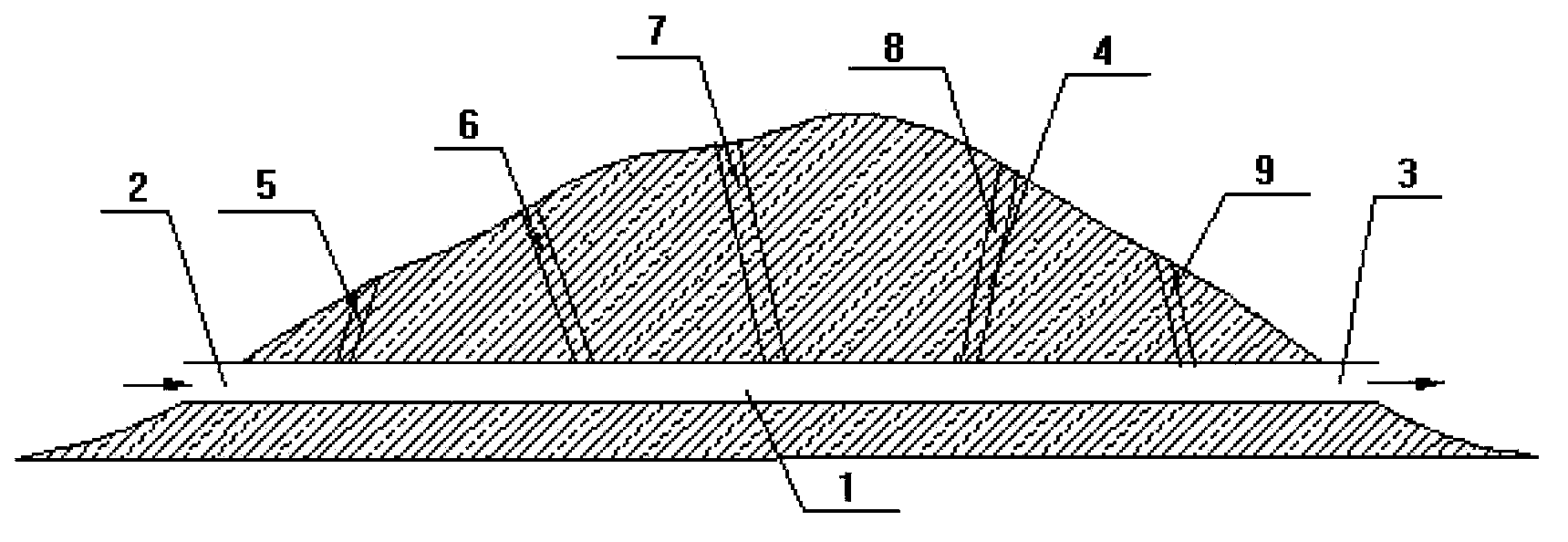

[0016] Such as figure 1 As shown, in the high-speed railway tunnel structure of the present invention, openings 4 are arranged on the top of the lining of the tunnel 1, and the openings 4 are five evenly arranged, the first opening 5, the second opening 6, the third opening 7, the fourth opening 8, Fifth opening9. The distance between the first opening 5 and the tunnel entrance opening 2 and the distance between the fifth opening 9 and the tunnel exit opening 3 is 20-50m. In order to effectively reduce the peak value of the micro-pressure wave at the entrance, the transient pressure in the locomotive, the additional air resistance of the locomotive, and the aerodynamic load in the tunnel. The opening 4 at the top of the tunnel 1 is realized by a horizontal shaft or an inclined shaft.

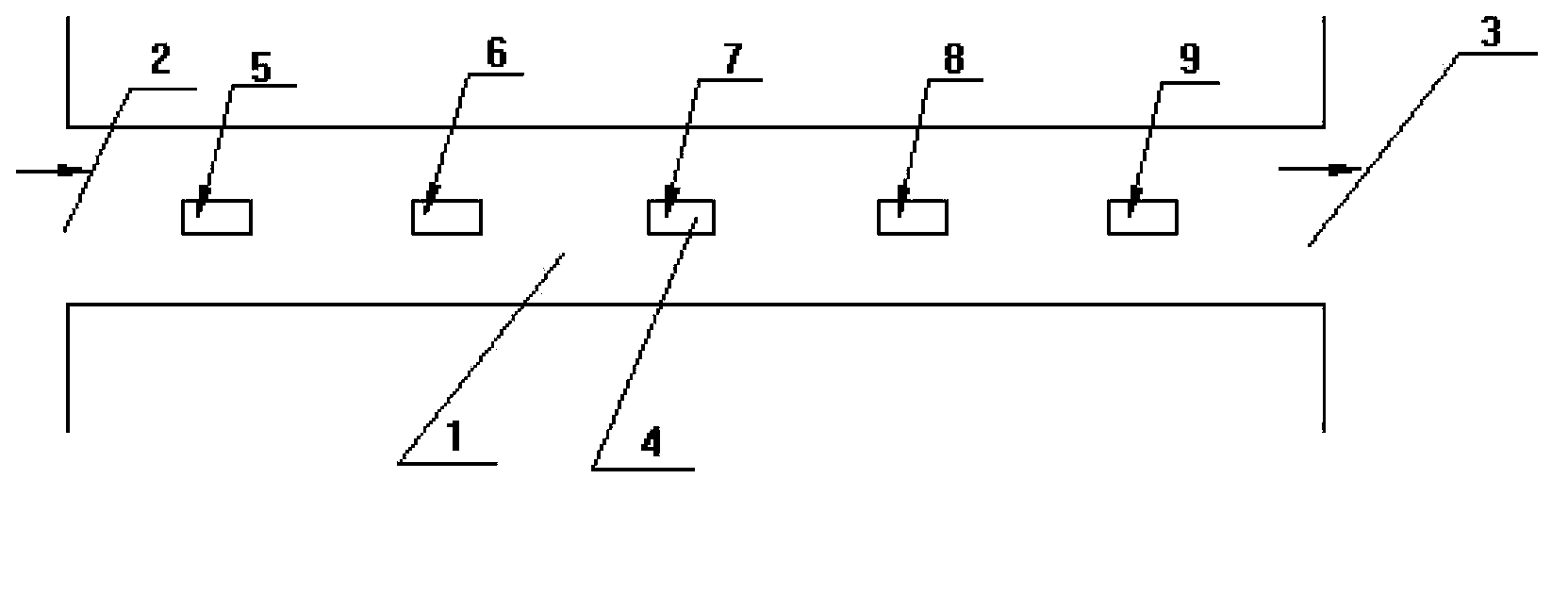

[0017] Such as figure 2 As shown, in the high-speed railway tunnel structure of the present...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com