City tunnel ventilation test device and manufacturing method thereof

A tunnel ventilation and test device technology, which is applied in mine/tunnel ventilation, earthwork drilling, mining equipment, etc., can solve the problems of lack of visualization of gas flow, disturbance of flow field, and influence of detection accuracy, etc., and achieve visualization of flow field , similar flow resistance and low test cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

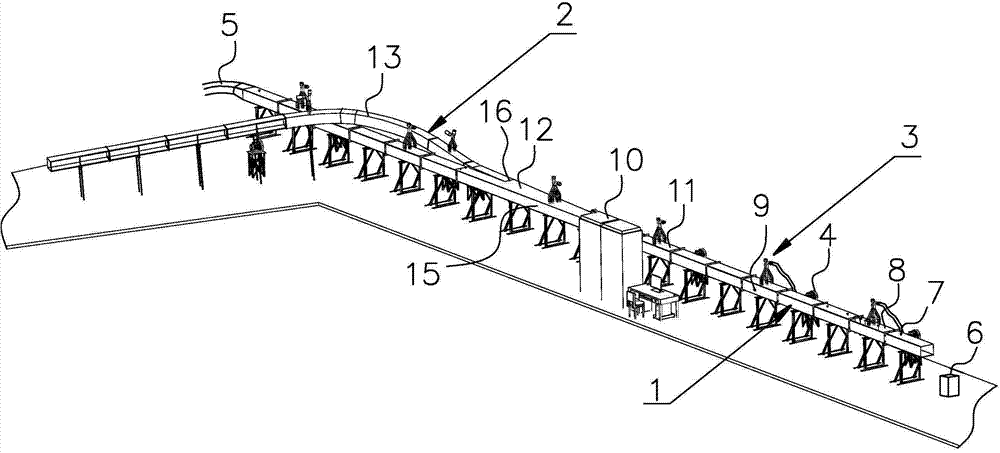

[0066] Such as figure 1 As shown, the present embodiment is a kind of urban tunnel ventilation test device, and the prototype of this urban tunnel ventilation test device is the Zijingang Tunnel in Xihu District, Hangzhou City. ; The total length of the B ramp tunnel is 560m, and the length of the grounding U-shaped slot is 186m; the total length of the C ramp tunnel is 159m, and the length of the grounding U-shaped slot is 130m. The cross-section of the main tunnel is a single-box double-chamber rectangular section with a net height of 5.5m and a net width of 9.75m, of which the net height of the fan section is 6.7m. The clear height of the ramp is the same as that of the main tunnel, the clear width is 7.5m, and the inner wall is made of rough concrete.

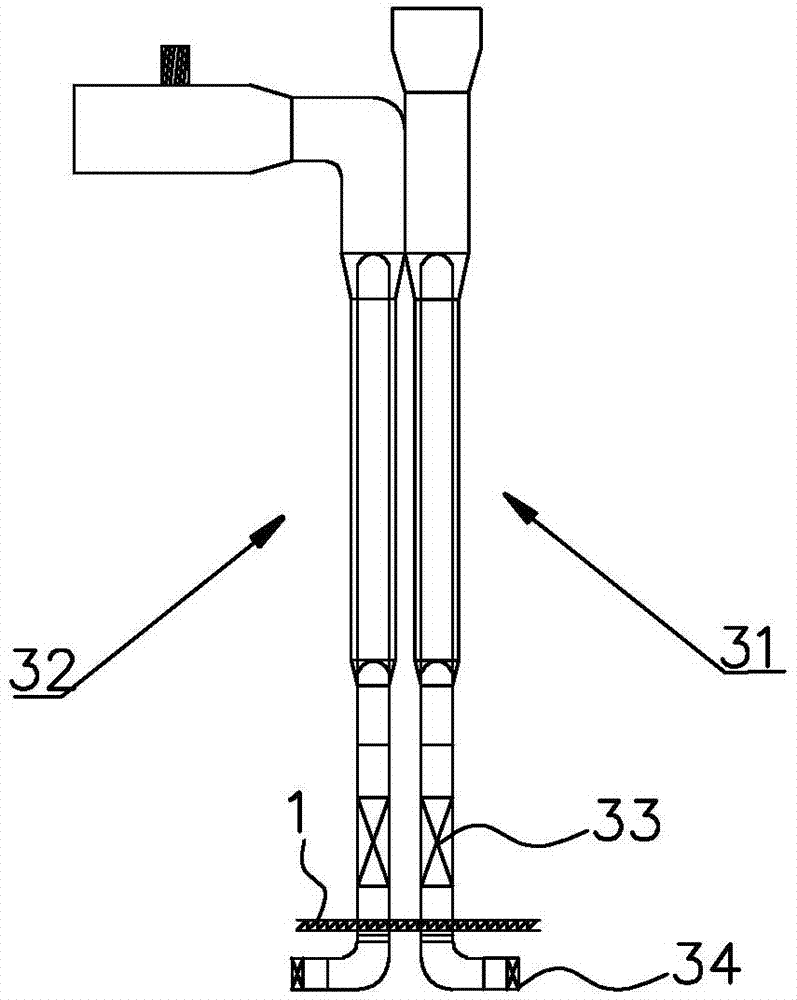

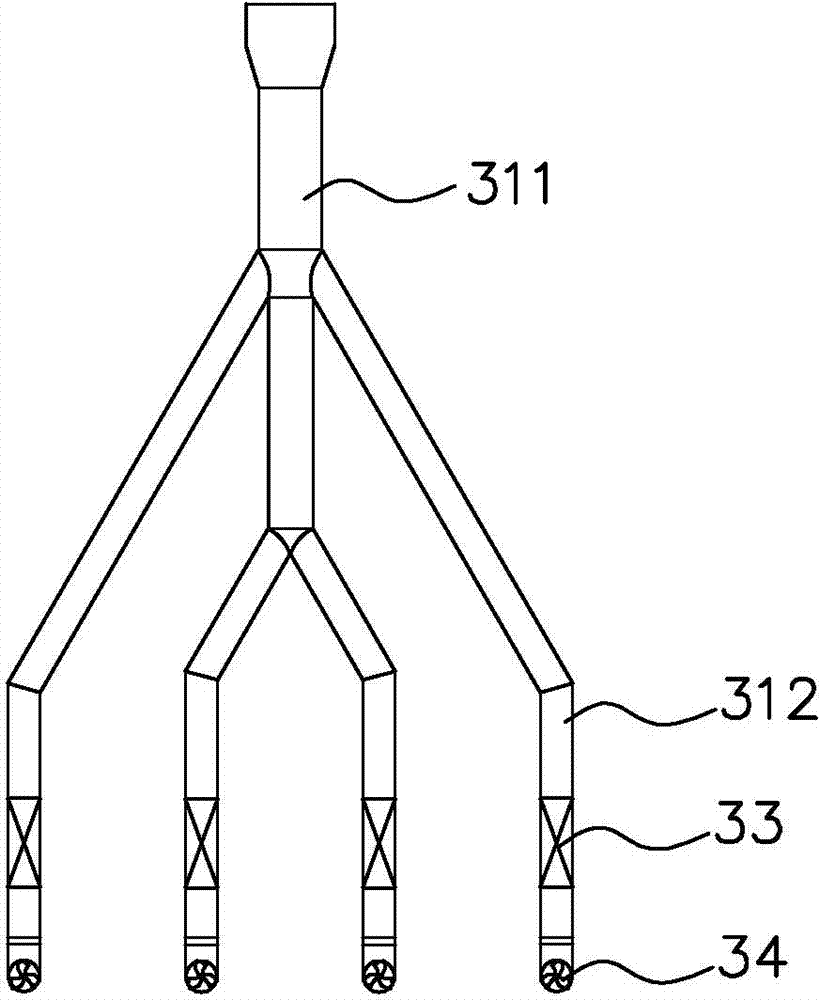

[0067] The urban tunnel ventilation test device of the present embodiment co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com