Automatic manufacturing device for inner tank of freezer and freezer

A technology for manufacturing equipment and refrigerators, which is applied in the direction of manufacturing tools, heat exchange equipment, metal processing equipment, etc., can solve the problems of low degree of refinement, low heat exchange efficiency of the inner tank, and slow production tempo, so as to improve quality, Improve the heat exchange efficiency and increase the beat effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

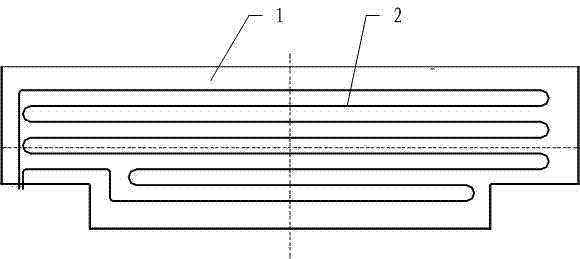

[0065] The invention proposes a brand-new automatic manufacturing equipment for the inner tank of the refrigerator, which changes the traditional inner tank structure assembled from multiple boards. The inner tank includes an integral coaming and an integral bottom plate. The flat plate of the tube group is bent and formed as a whole, and the integral bottom plate is bent and formed separately, and then the integral hoarding and the integral bottom plate are kneaded and buckled to form. The processing procedure is simple and the degree of refinement is high. Specifically, the fabrication process employs the following steps:

[0066] refer to Figure 1-9 as shown,

[0067] (1) Firstly lay the flat plate to be made into the integral coaming 1 on the automatic conveying line, and perform various punching, folding and flipping; the flat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com