Cross-flow filler testing platform used for cooling tower

A technology of a test bench and a cooling tower is applied in the field of research and testing equipment for the basic data of the thermal performance of the cross-flow cooling tower, which can solve the problems of poor testing accuracy, lack of testing methods, and low use significance, and achieve stable air volume testing and measurement accuracy. High, avoid waste effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

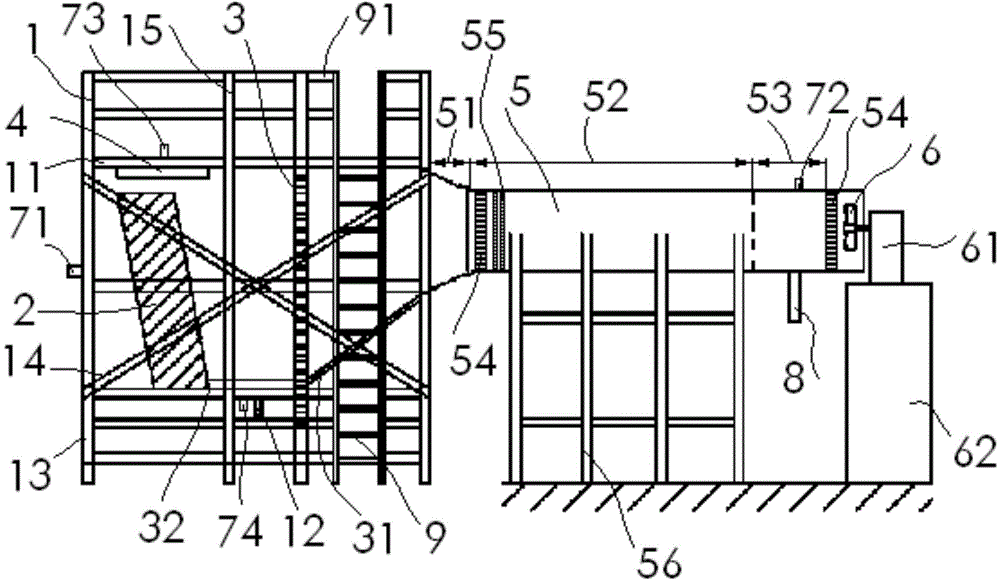

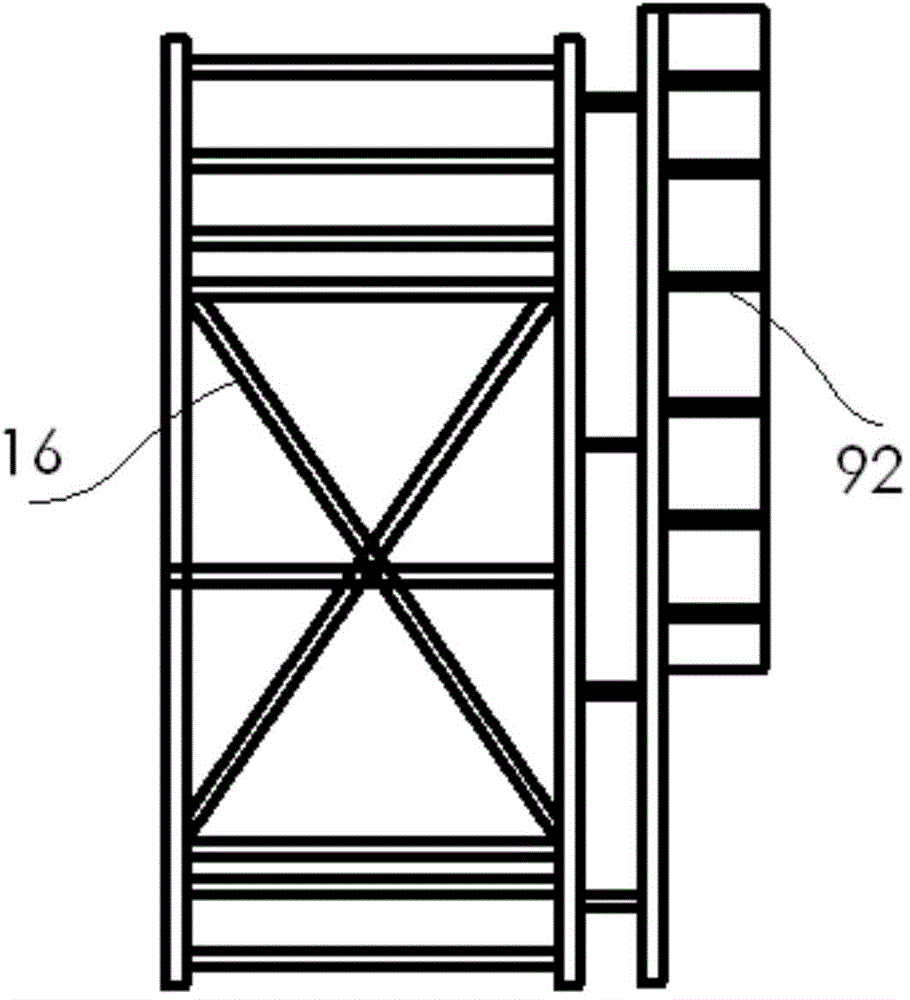

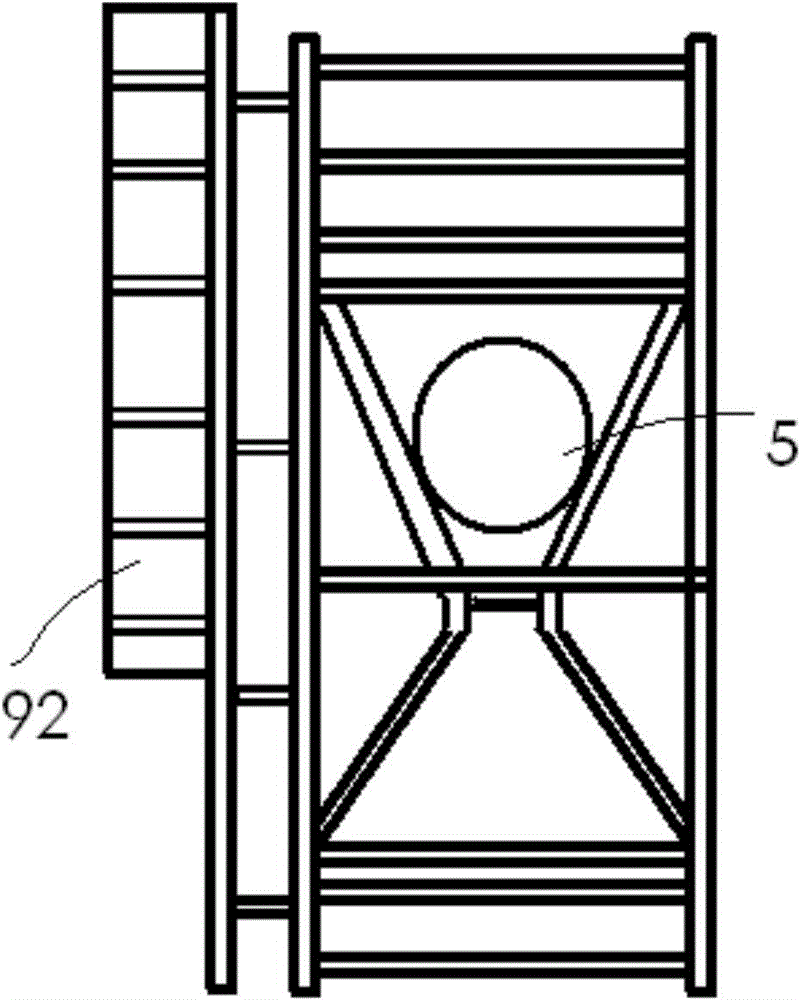

[0038] Example: such as Figure 1-3 As shown, a cross-flow filling test bench for cooling towers includes a framework 1 of a square frame structure, panels are welded on the front side, rear side and bottom of the framework 1, and a sealing plate 11 is arranged on the top of the framework. The interior is provided with air inlets, packing areas 2 and rectifying water blocking curtain 3 at intervals from left to right, and the right side of rectifying water blocking curtain 3 to frame 1 is a transition area for preventing vortex and filtering water drops; The lower bottom surface of the sealing plate 11 is fixedly connected with a shower tank 4, and the lower part of the shower tank 4 is opposite to the packing area 2; the outer surface of the upper part of the right side of the skeleton 1 is connected with a fan tube 5 along a horizontal direction, and the fan tube 5 is close to the right port. Axial-flow FRP fan 6 is installed in the position.

[0039] This test bench has: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com