Metal mobile phone shell and mobile phone

A mobile phone shell and metal shell technology, applied to the structure of telephones, etc., can solve the problems of strong visual heaviness, heavy visual sense, and single appearance, and achieve slim visual effects, enhanced diversity, and cool appearance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

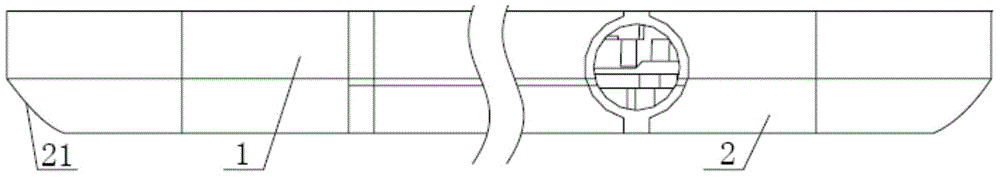

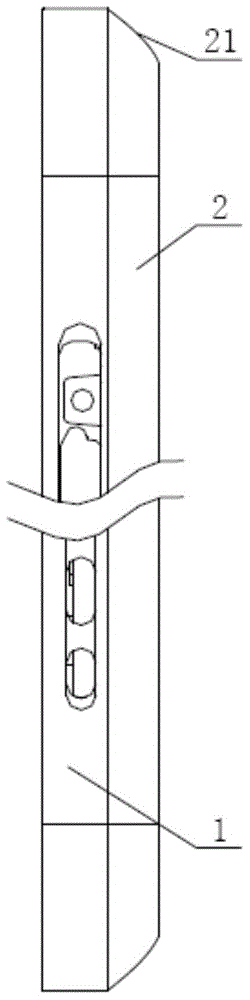

[0031] This embodiment provides the first metal mobile phone case, the structure of the metal mobile phone case is as follows: figure 1 and figure 2 As shown, it includes a middle frame 1 and a battery back cover 2, and the middle frame 1 and the battery back cover 2 form an integrated metal shell structure.

[0032] As a preferred embodiment, the middle frame 1 has a square frame structure, and the battery back cover 2 includes a bottom wall and two side walls symmetrically arranged and connected to the bottom wall, both of which are wide at the top and narrow at the bottom and protruding The arc-shaped surface 21 of the battery back cover 2 is connected to the side walls of the middle frame 1 respectively. In this way, the maximum width of the battery back cover 2 is equal to the width of the middle frame 1, and the battery back cover 2 The width of the bottom wall is smaller than the width of the middle frame 1. Viewed from the side, a stepped structure is formed between...

Embodiment 2

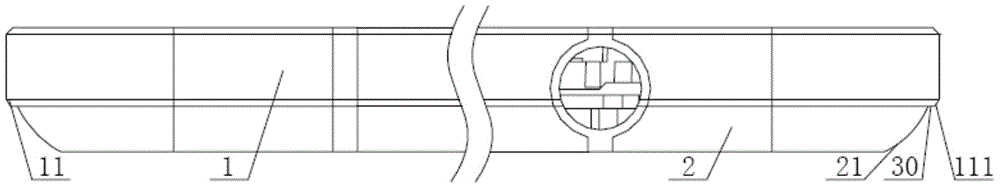

[0037] This embodiment provides the second metal mobile phone shell, such as image 3 and Figure 4 As shown, the difference between the metal mobile phone casing structure described in this embodiment and the metal mobile phone casing structure described in Embodiment 1 is:

[0038] Both upper and lower edges of the side wall of the middle frame 1 are provided with chamfers 11, and the chamfers 11 are straight edge chamfers, and may also be circular arc chamfers. The angle of chamfer 11 can be controlled in the range of 10-60°, and its specific value can be designed according to actual production needs.

[0039] As a preferred solution, the lower end of the side wall of the middle frame 1 is also provided with a connection surface extending toward the middle of the middle frame 1, where the connection surface is connected to the chamfer slope 111 of the chamfer 11 and is connected to the metal mobile phone casing. The middle part of the first horizontal plane 30 extends. T...

Embodiment 3

[0043] This embodiment provides a third metal mobile phone casing, which is slightly improved on the basis of the metal mobile phone casing structure described in Embodiment 2, as Figure 5 and Figure 6 As shown, the difference between the metal mobile phone casing structure described in this embodiment and the metal mobile phone casing structure described in Embodiment 2 is:

[0044] The connection surface includes a second horizontal surface 31, a straight support surface 32 and a transition surface 33. The straight support surface 32 is arranged perpendicular to the battery back cover 2. The transition surface 33 is a concave curved surface with a wide top and a narrow bottom. The second horizontal surface 31 is in line with the implementation The extension direction and structure of the first horizontal plane described in Example 2 are the same. Furthermore, the edge of the second horizontal plane 31 is connected to the lower edge of the chamfered slope 111 of the upper c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com