Integrated cutting and feeding mechanism of cold heading machine

A feeding mechanism and integrated technology, which is applied in the field of integrated shearing and feeding mechanism, can solve the problems affecting the machining efficiency of cold heading machine, machining accuracy, and long feeding action period, etc., so as to improve machining economic benefits, improve machining efficiency and machining accuracy. , the effect of improving product production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

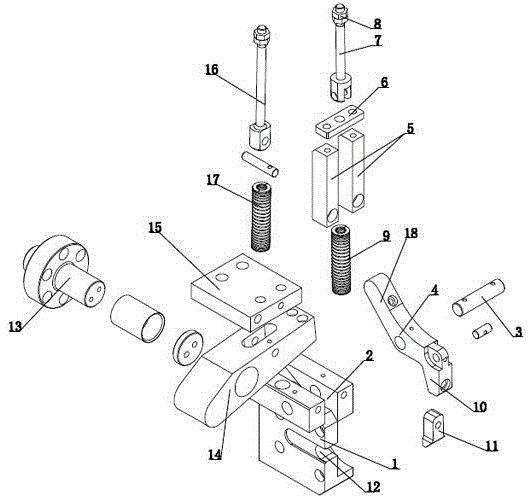

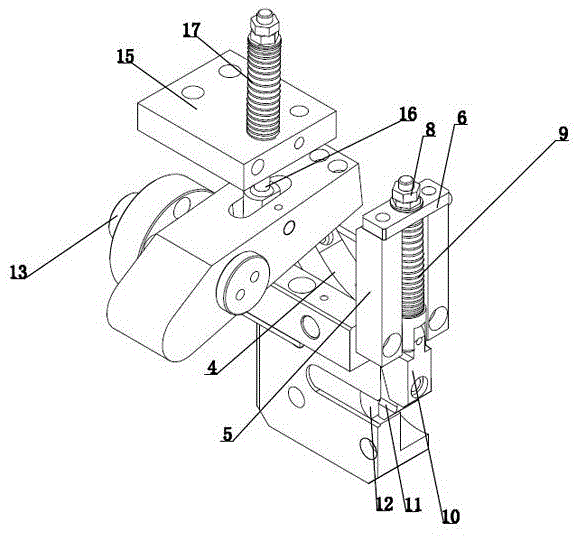

[0029] Such as figure 1 and 2As shown, the integrated shearing and feeding mechanism of a cold heading machine provided in this embodiment includes a scissor plate 1, and an installation groove 2 is opened on the top of the scissor plate 1, and a pair of installation grooves 2 The auxiliary clip shaft 3 is hinged with a scissors auxiliary lever 4 between the side walls of the groove. An auxiliary clip elastic element longitudinal support 5 is also fixed, and an auxiliary clip elastic element transverse support 6 is jointly supported on the above-mentioned two auxiliary clip elastic element longitudinal supports 5, and an auxiliary clip runs through the auxiliary clip elastic element transverse support 6. The elastic element shaft 7, the auxiliary clip elastic element shaft 7 passes through the auxiliary clip elastic element transverse support 6, and is axially limited by screwing a hexagon nut assembly 8, and the above-mentioned auxiliary clip elastic element shaft 7 is sleev...

Embodiment 2

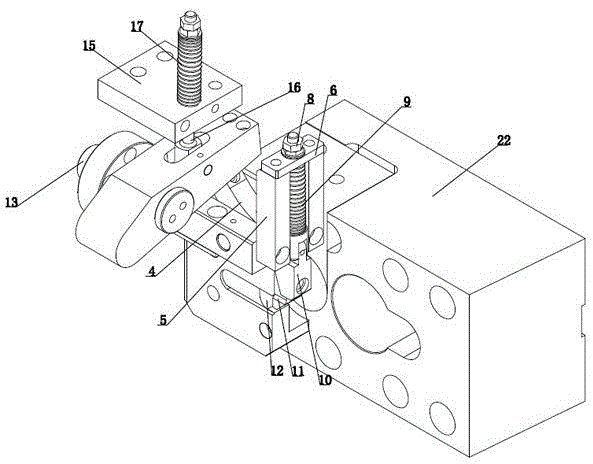

[0032] The integrated shearing and feeding mechanism of a cold heading machine provided in this embodiment has a general structure consistent with that of Embodiment 1, such as Figure 5 As shown, but in the present embodiment, an end portion of the paw release lever 14 is additionally provided with a paw release lever press bar 23, which is in a mutual transmission structure with the relative high end 18 of the above-mentioned scissors auxiliary lever 4.

Embodiment 3

[0034] The integrated shearing and feeding mechanism of a cold heading machine provided in this embodiment has a general structure consistent with that of Embodiment 2, such as Figure 6 and Figure 7 As shown, but in this embodiment, the scissors board 1 is also fixed with a wire stopper 24, and the wire stopper 24 is provided with a stopper notch 25 overlapping with the scissors mouth 12 of the scissors board 1 above.

[0035] The addition of the above-mentioned wire stopper 24 can increase the axial contact area between the scissors mouth 12 and the wire, thereby improving the clamping stability of the auxiliary scissors clip 11 during the entire cutting and feeding process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com