Antimony smelting reverberatory furnace batching device

A reverberatory furnace, antimony oxide technology, applied in furnaces, furnace components, lighting and heating equipment, etc., can solve the problems of large blanking volume, loss of antimony oxide powder, flying antimony oxide powder, etc., to prolong the service life, Eliminate the effect of flying and speeding up

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

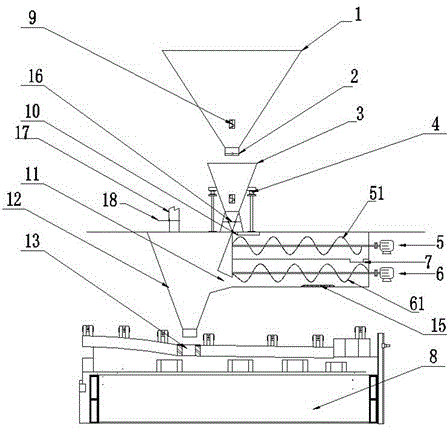

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0029] Refer to the accompanying drawings: a batching device for antimony smelting reverberatory furnace, including antimony oxygen bin 1, vibrator 9, valve 2, feed hopper 12, reverberatory furnace feed port 13 and reverberatory furnace 8, between antimony oxygen bin 1 and feed Measuring buckets 3 are arranged between the buckets 12 . The metering bucket 3 is provided with a metering module 4 . There are two screw mixers 5 and 6 under the metering hopper 3 . There is a primary rotary feeding port 10 between the metering hopper 3 and the screw mixer 5, a secondary rotary feeding port 7 is provided between the screw mixer 5 and the screw mixer 6, and a rotary feeding port 11 is provided on the right side of the screw mixer 6. .

[0030] A flow guiding device 16 is added between the metering hopper 3 and the screw mixer 5 . Once the screw mixer breaks down, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com