Patents

Literature

30 results about "Antimony isotope" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Antimony has two stable isotopes: 121Sb with a natural abundance of 57.36% and 123Sb with a natural abundance of 42.64%. It also has 35 radioisotopes, of which the longest-lived is 125Sb with a half-life of 2.75 years.

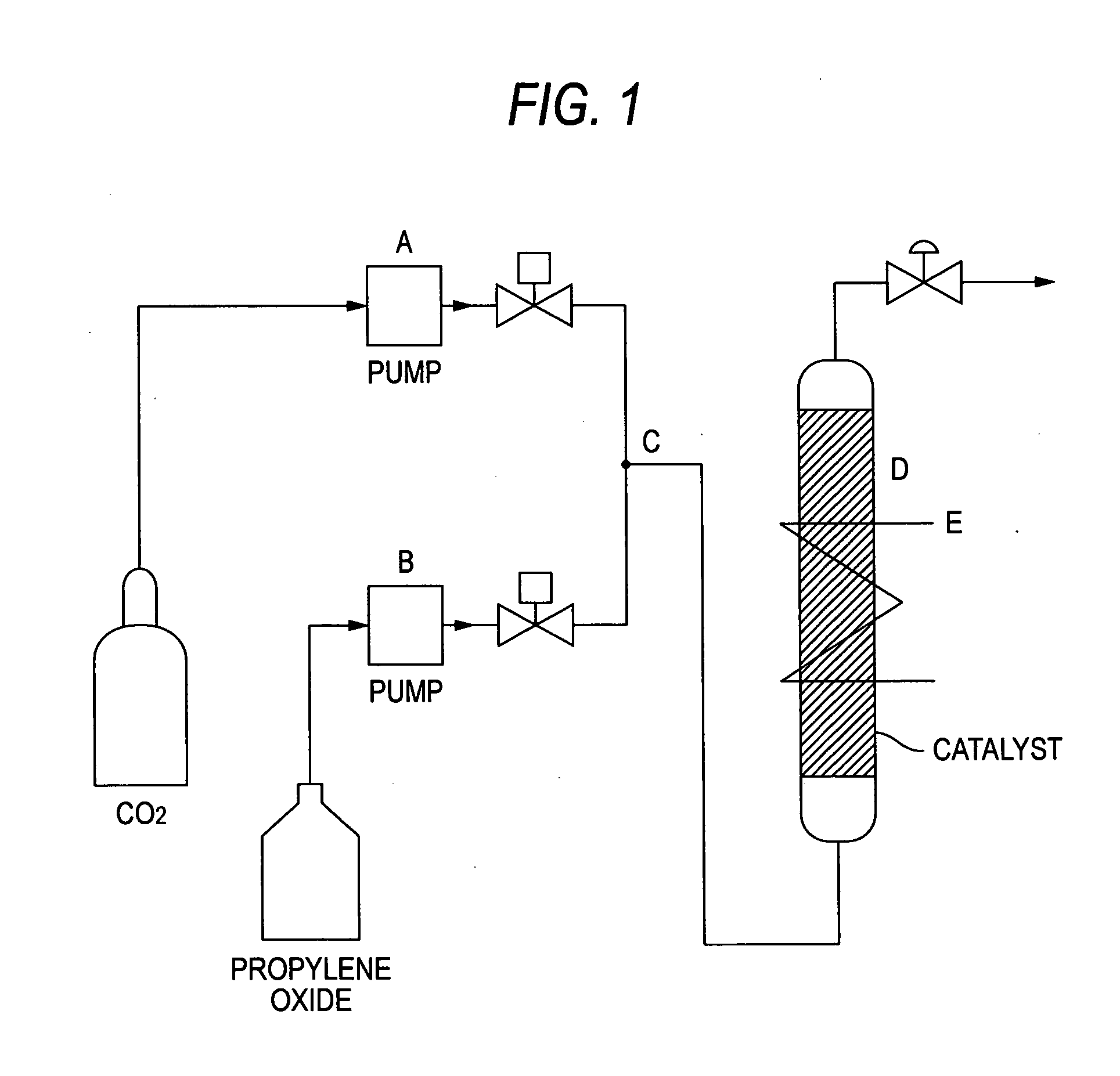

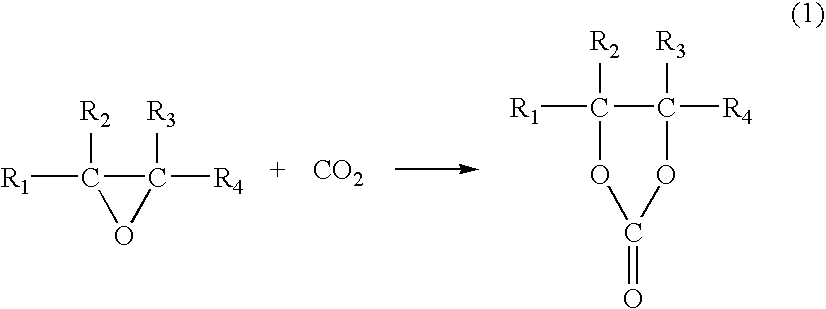

Catalyst for Cyclic Carbonate Synthesis

InactiveUS20080214386A1High yieldSolution to short lifeOrganic chemistryMolecular sieve catalystsPhosphoniumPhosphonium salt

Provided are a solid catalyst which gives a cyclic carbonate at a high yield and a high selectivity, which is stable and which may be readily separated after reaction; and a method of industrially advantageous, inexpensive and safe production of a cyclic carbonate by the use of the catalyst. The catalyst contains an inorganic solid substance having a surface modified with an ionic substance containing a Group 15 element; or contains an ionic substance containing a Group 15 element, and an inorganic solid substance. The modifying group for surface modification of an inorganic solid substance is an ionic substance containing a Group 15 element. The ionic substance containing a Group 15 element is at least one substance selected from organic phosphonium salts, organic ammonium salts, organic arsonium salts and organic antimonium salts.

Owner:NAT INST OF ADVANCED IND SCI & TECH

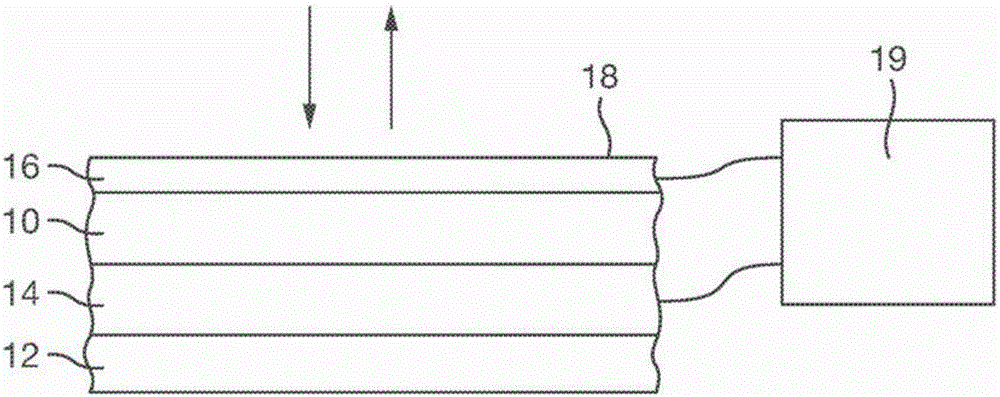

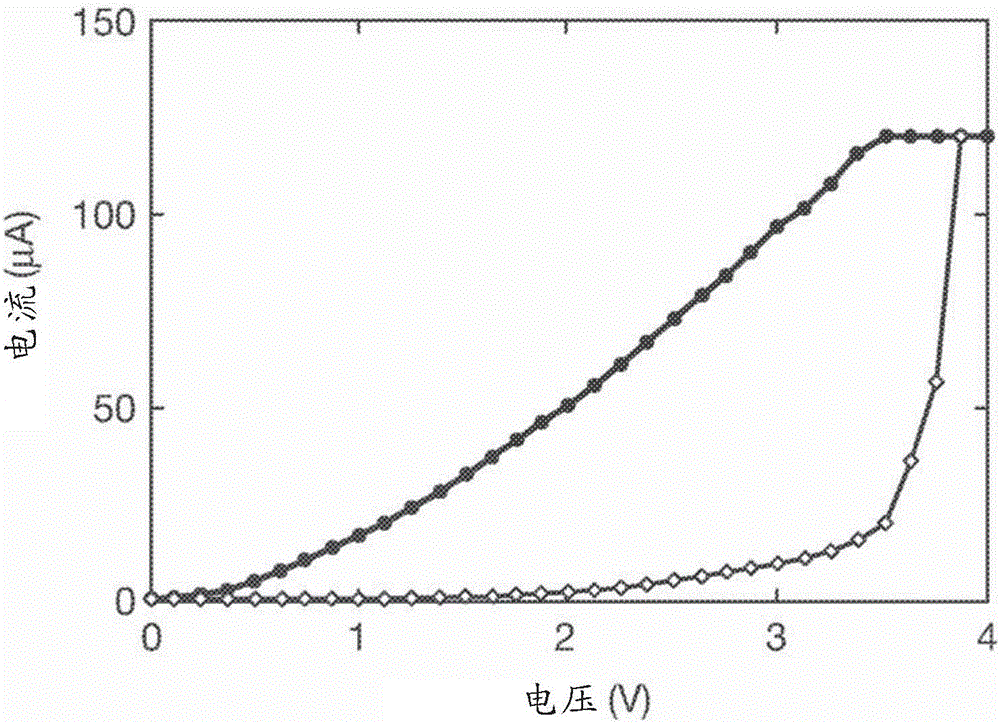

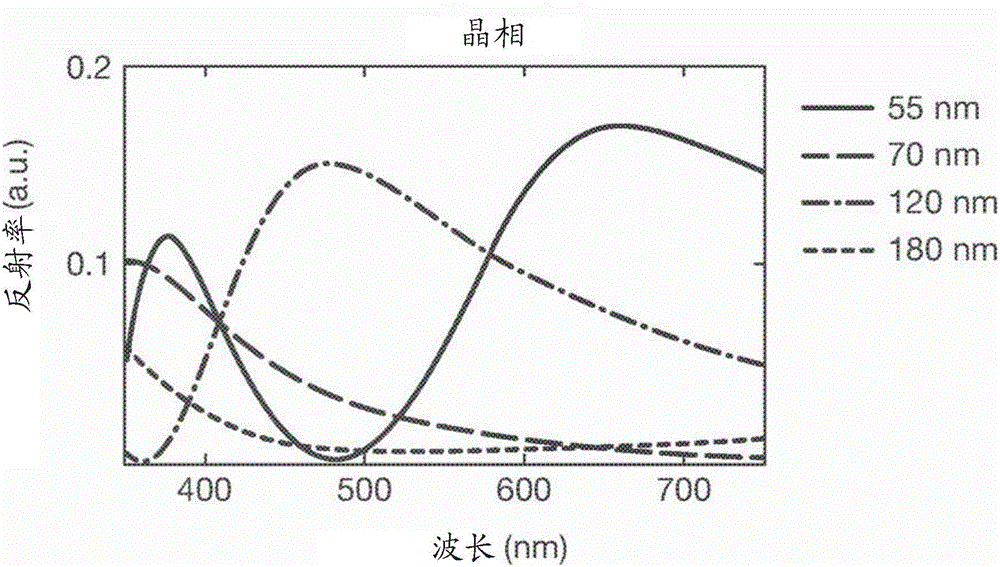

Display device based on phase-change materials

ActiveCN105849626AHigh speed manufacturingRun at high speedNon-linear opticsOptical elementsVanadium dioxideRefractive index

A display device comprises a plurality of pixels, each pixel having a portion (10) of a solid-state, phase-change material such as germanium-antimonium-telluride (GST) or vanadium dioxide, wherein the phase-change material can be reversibly brought into an amorphous state or a crystaline state and has a refractive index that is reversibly, electrically controllable. A plurality of electrodes (14, 16) are provided, at least two of which contact said portion of material (10). A controller (19) is provided that is adapted to apply at least one voltage to said material (10), via said electrodes (14, 16), to change said refractive index. An array of such portions of material can be arranged to make a pixellated display, for example a stereoscopic display of the volumetric type.

Owner:OXFORD UNIV INNOVATION LTD

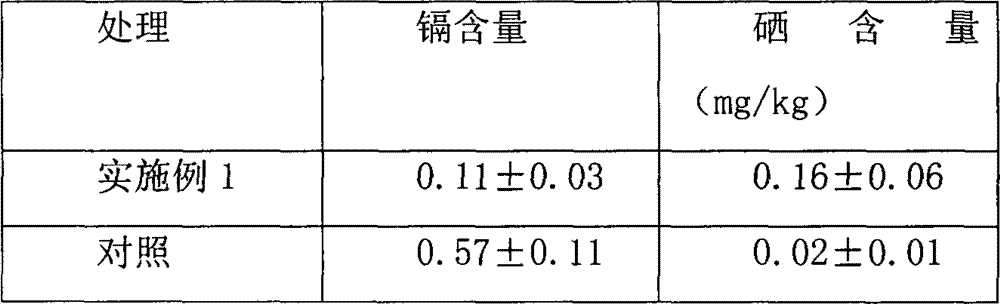

Heavy-metal-resistant plant growth detoxification accelerant and method for using same

InactiveCN102964177APromote photosynthesisHigh in proteinBiocidePlant growth regulatorsSelenateGrowth plant

The invention discloses a heavy-metal-resistant plant growth detoxification accelerant and a method for using the same. The accelerant is characterized by containing low dose of one of selenate or selenite, wherein an amino acid micro element fertilizer is also added, and the accelerant is sprayed onto the leaves for a plurality of times during a period of 7-40 days before crops are harvested. A method for preparing and the method for using are simple and practicable and are convenient to popularize. By the accelerant, the contents of heavy metals of cadmium, antimonium and the like in the crops can be effectively reduced, the crop yield and quality are improved, and the problem that most people in China insufficiently intake selenium can be relieved through a method of reasonably increasing selenium contents in agricultural products, so that the production safety of the agricultural products in heavy metal pollution regions is effectively guaranteed.

Owner:AGRO ENVIRONMENTAL PROTECTION INST OF MIN OF AGRI

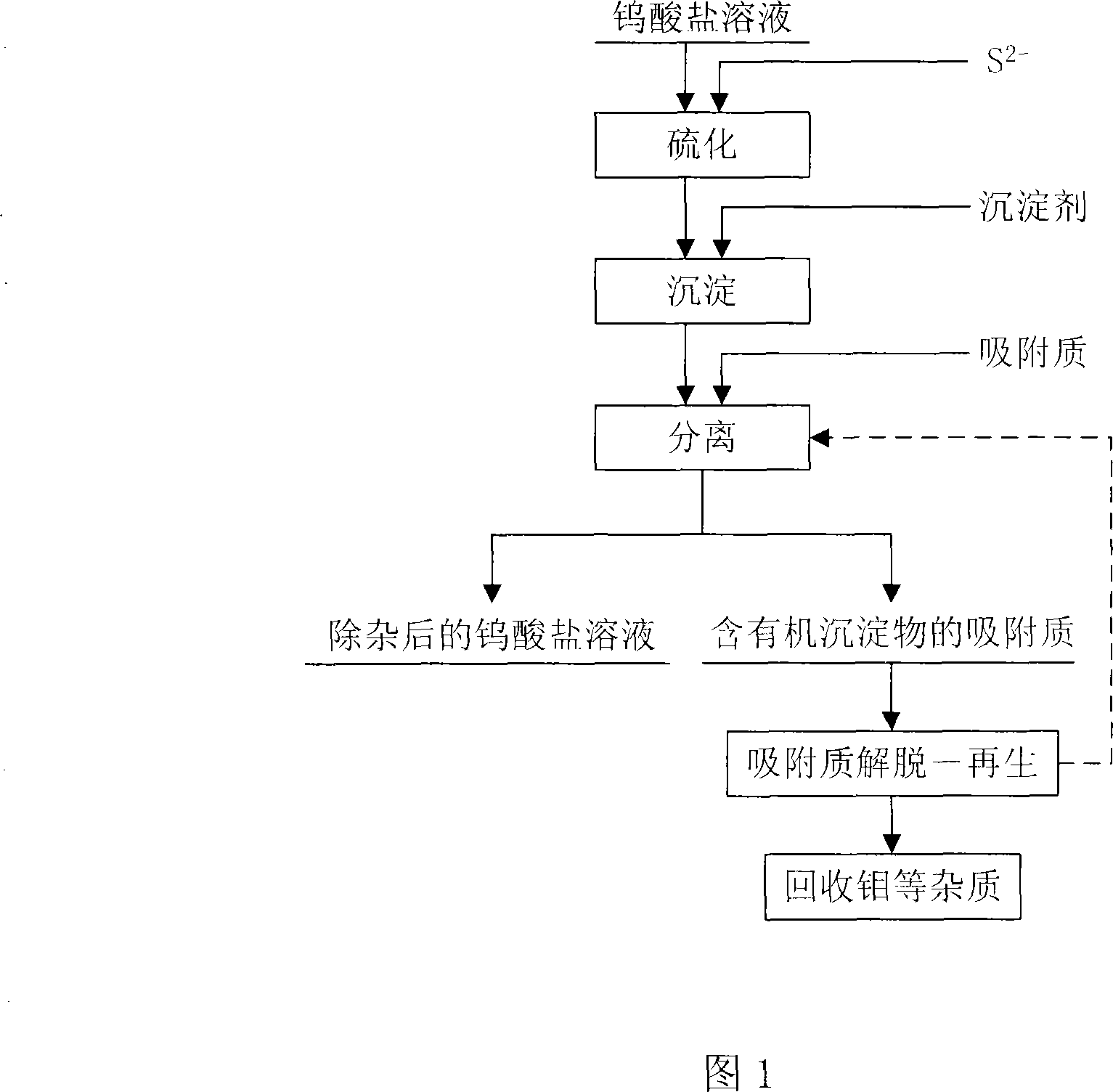

Method for removing molybdenum, arsenic, antimony and stannum from tungstate solution

ActiveCN101177303AGood effect of removing impuritiesReduce manufacturing costTungsten compoundsTungstateOrganic compound

The invention discloses a method of removing molybdenum, arsenic, antimony and tin from the tungstate solution, which belongs to technical field of chemistry and metallurgy. The invention is characterized in that firstly, the tungstate solution is vulcanized; secondly, the precipitator is added and mixed with the thiosalt of the impurity to form the organic compound sediment; thirdly, the adsorbate is added to process filter and separation; fourthly, the filtrate is tungstate solution without impurity, the filter residue is the adsorbate and the organic compound, the adsorbate can be reused through extrication- regeneration. The invention has the advantages of good performance of impurity removal, simple equipment, low production cost, short process, and convenient operation.

Owner:GRIMAT ENG INST CO LTD

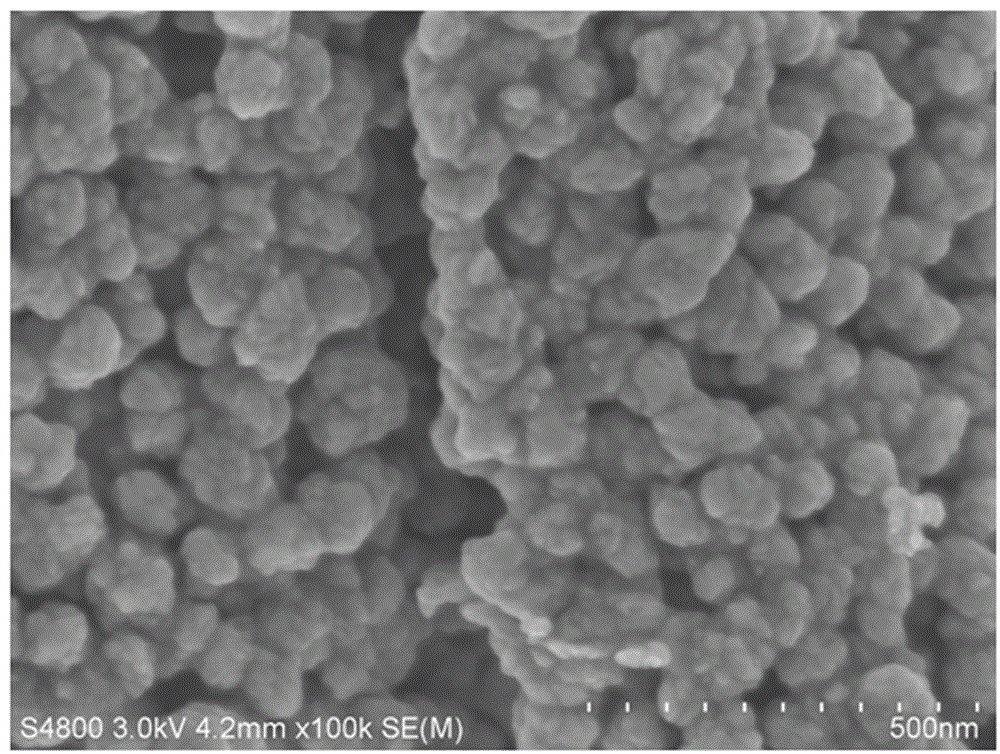

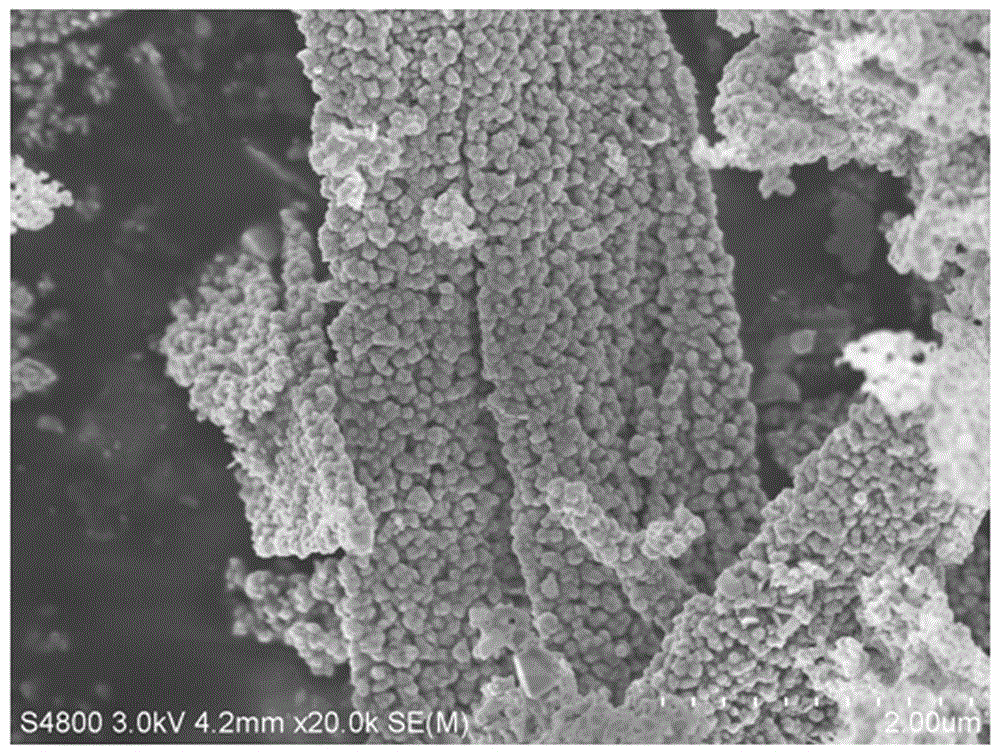

Method for preparing pyrophillite-based antimony-doped tin oxide compound conductive powder

InactiveCN102249293AReduce manufacturing costImprove use valueCable/conductor manufactureTin oxidesAntimonateMaterials science

The invention discloses a method for preparing pyrophillite-based antimony-doped tin oxide compound conductive powder. The method is characterized in that a chemical precipitation process for respectively dropwise adding a tin salt and an antimony salt is adopted. The method is a preparation method for the compound conductive powder, the surface of which is covered with a layer of antimony-doped tin oxide. The method provided by the invention can be used for reducing the preparation cost of conductive powder. The acquired powder has light color and excellent conductivity.

Owner:HANGZHOU TENGSHI TECH

Leadless alloy thread preparation

The invention provides a method for producing leadless alloy wires. The method includes the following steps: the first step: compounding copper, antimonium, stannum and zinc at a ratio, melting the compounded mixture in a melting furnace, stirring intensively, cooling, and performing die-casting to obtain a cylindrical Zn / Sn alloy; the second step: extruding the cylindrical Zn / Sn alloy in an extrusion press under heating to form wire materials, subjecting the wire materials to the first-stage wire-drawing treatment using a speed-down wire-drawing machine and performing the second-stage wire-drawing treatment using a single-head wire-drawing machine to obtain the Zn / Sn alloy wire. The method can effectively control the melting temperature, thereby preventing the metal film from being burned.

Owner:戴兴无

Prepn process of composite tin oxide conducting powder with blended antimony and RE

The preparation process of composite tin oxide conducting powder with blended antimony and RE includes the following steps: 1. compounding mixture solution with RE oxide(s), tin powder, antimony oxide, complexant and nitric acid; 2. compounding alkali solution with ammonia water; 3. dispersing conducting core material in water solution; 4. dropping simultaneously the mixture solution a the alkali solution into deionized water while stirring to obtain precipitant; and 5. washing the precipitant separately with deionized water and organic solvent under stirring, stoving, grinding, sieving and calcining to obtain the composite tin oxide conducting powder with blended antimony and RE. Thus prepared composite tin oxide conducting powder has obviously raised use temperature over 900 deg.c.

Owner:SHANGHAI INST OF TECH

High-tellurium copper slag treatment method

ActiveCN107201448AHigh recovery rateAchieve the purpose of separationElectrolysis componentsProcess efficiency improvementBismuthMaterials science

The invention discloses a high-tellurium copper slag treatment method. The high-tellurium copper slag treatment method comprises the following steps of: (1) ball-milling; (2) acidifying; (3) low-acid leaching; (4) bismuth precipitating; (5) copper precipitating; (6) high-acid pickling; (7) gold, sliver and lead recycling; (8) solution replacing; (9) antimonium precipitating; (10) tellurium leaching; (11) purifying; (12) neutralizing and tellurium precipitating; and (13) electrolyzing and tellurium extracting. The method disclosed by the invention can be adopted to clean and efficiently treat copper slag, comprehensively recycles noble metals such as gold, silver, tellurium, antimonium, bismuth and copper, and radically solves the problems such as a lagged process, poor comprehensive utilization, a low metal recovery rate and severe environmental pollution of the conventional method.

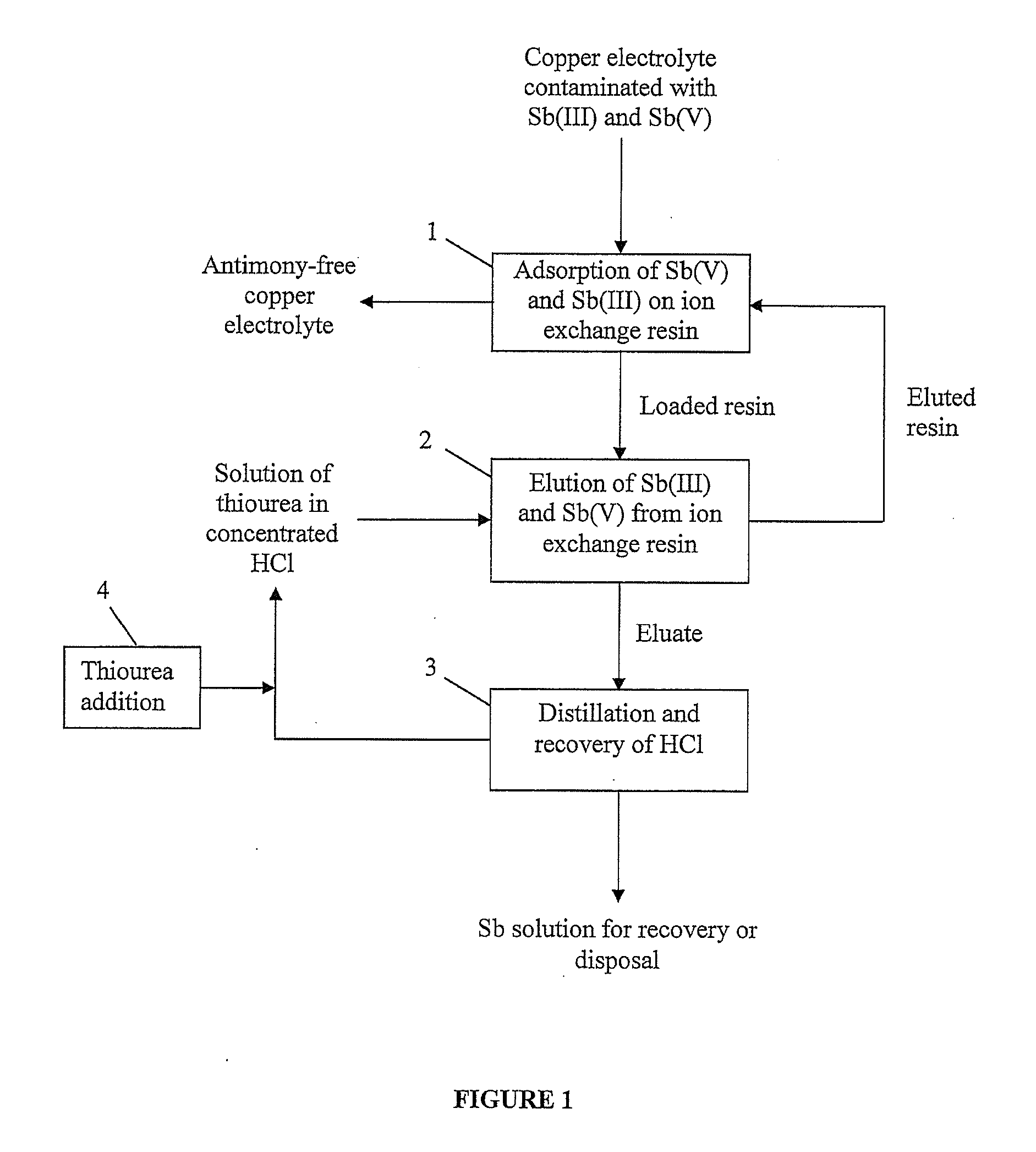

Method to remove antimony from copper electrolytes

InactiveUS20100230294A1Fine surfaceProcess compatibleIon-exchange process apparatusElectrolysis componentsIonAntimony isotope

A method and solution for eluting one of antimony(V) and a mixture of antimony(III) and antimony(V) from an ion exchange resin, comprises contacting the resin with an eluting solution comprising thiourea having a concentration of at least 0.002 M and hydrochloric acid having a concentration of at least 3 M. The method can be used for electrolytes in an industrial electrorefining process, by the further steps of contacting the electrolyte with an ion exchange resin to adsorb the antimony from the electrolyte and separating the resin from the electrolyte, before contacting the resin with the eluting solution comprising thiourea and hydrochloric acid. The method and solution address the difficulties of removing antimony(V), and allow for increased reuse of the resins.

Owner:HER MAJESTY THE QUEEN & RIGHT OF CANADA REPRESENTED BY THE MIN OF NATURAL RESOURCES

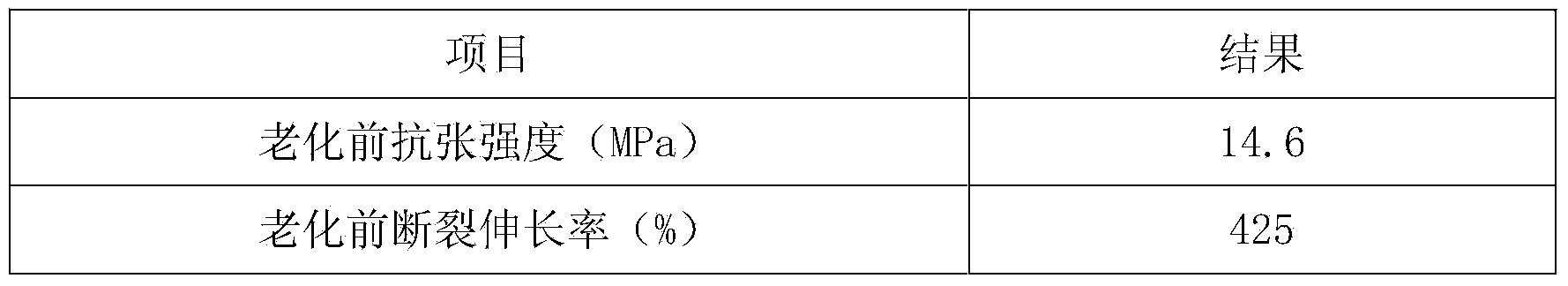

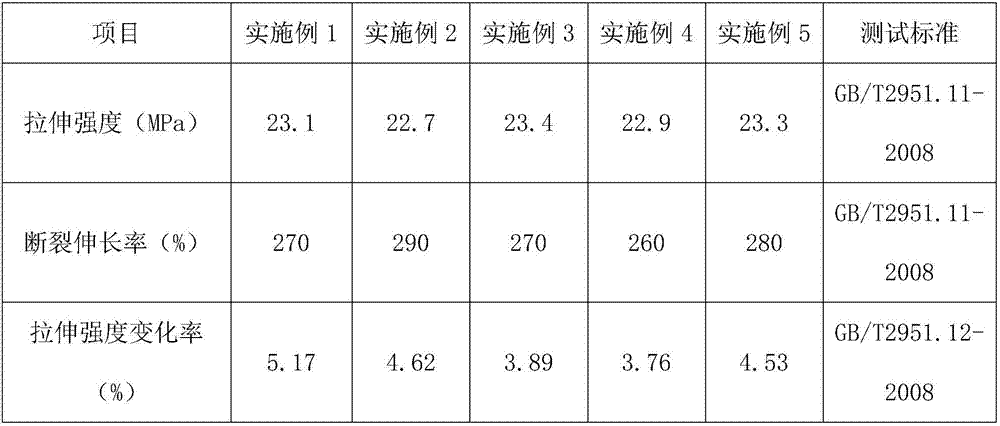

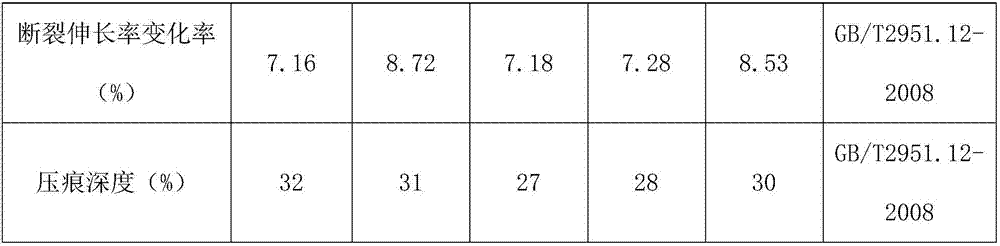

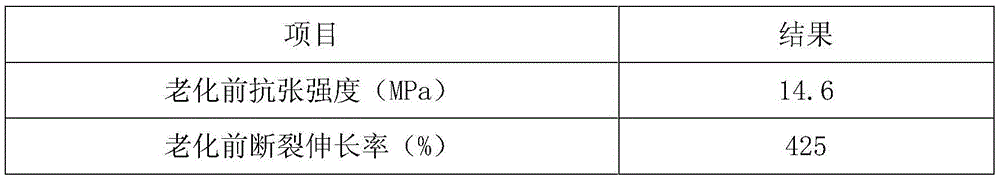

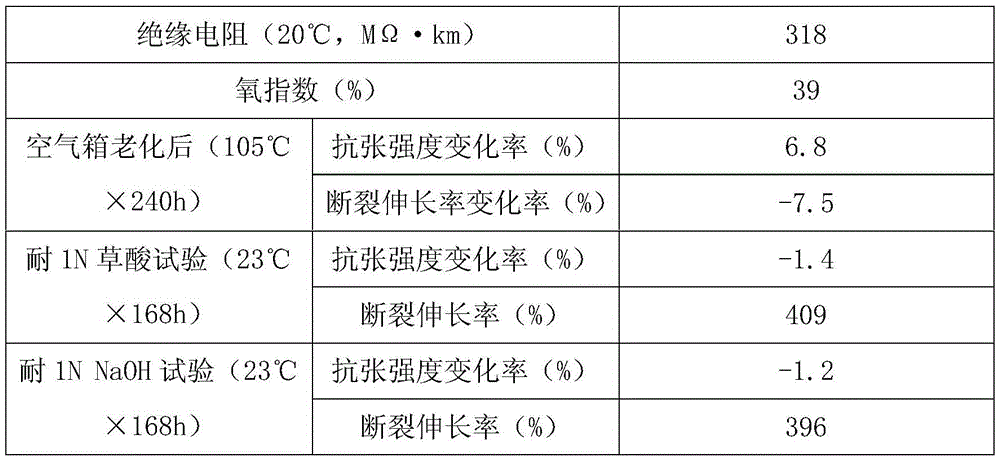

High-strength cable material used for railway vehicle, and preparation method thereof

ActiveCN104017365AHigh mechanical strengthImprove thermal stabilityPlastic/resin/waxes insulatorsGlycidyl methacrylatePhosphine oxide

The invention discloses a high-strength cable material used for a railway vehicle, and a preparation method thereof. The high-strength cable material is prepared from the following raw materials by weight: 85-105 parts of polyphenylene sulfide, 40-60 parts of aromatic polycarbonate, 25-35 parts of ethylene-methyl acrylate-glycidyl methacrylate terpolymer, 4-8 parts of diphenyl-methane-diisocyanate, 12-16 parts of bis(4-carboxyphenyl)phenyl-phosphine oxide, 10-15 parts of zinc aluminate, 20-30 parts of magnesium hydroxide,8-12 parts of basalt short fibers, 2-3 parts of methacryloyloxy propyltrimethoxysilane, 3-5 parts of tri-(stearic mercaptoacetate)antimonium, 2-3 parts of calcium stearate, 1.5-2.5 parts of barium stearate, 4-8 parts of erucyl amide, 3-6 parts of polyethylene wax, 15-20 parts of calcined clay, 10-15 parts of basic magnesium chloride whiskers, 20-30 parts of precipitated white carbon black, 14-18 parts of modified stone powder, 10-15 parts of epoxidized methyl acetorieinoleate and 2-3 parts of an antioxidant 1222. The cable material provided by the invention has the advantages of high mechanical strength, high flame retardance, fire resistance, good thermal stability, excellent electrical insulation property, wide usage temperature range, etc.

Owner:ANHUI KANGLIYA CO LTD

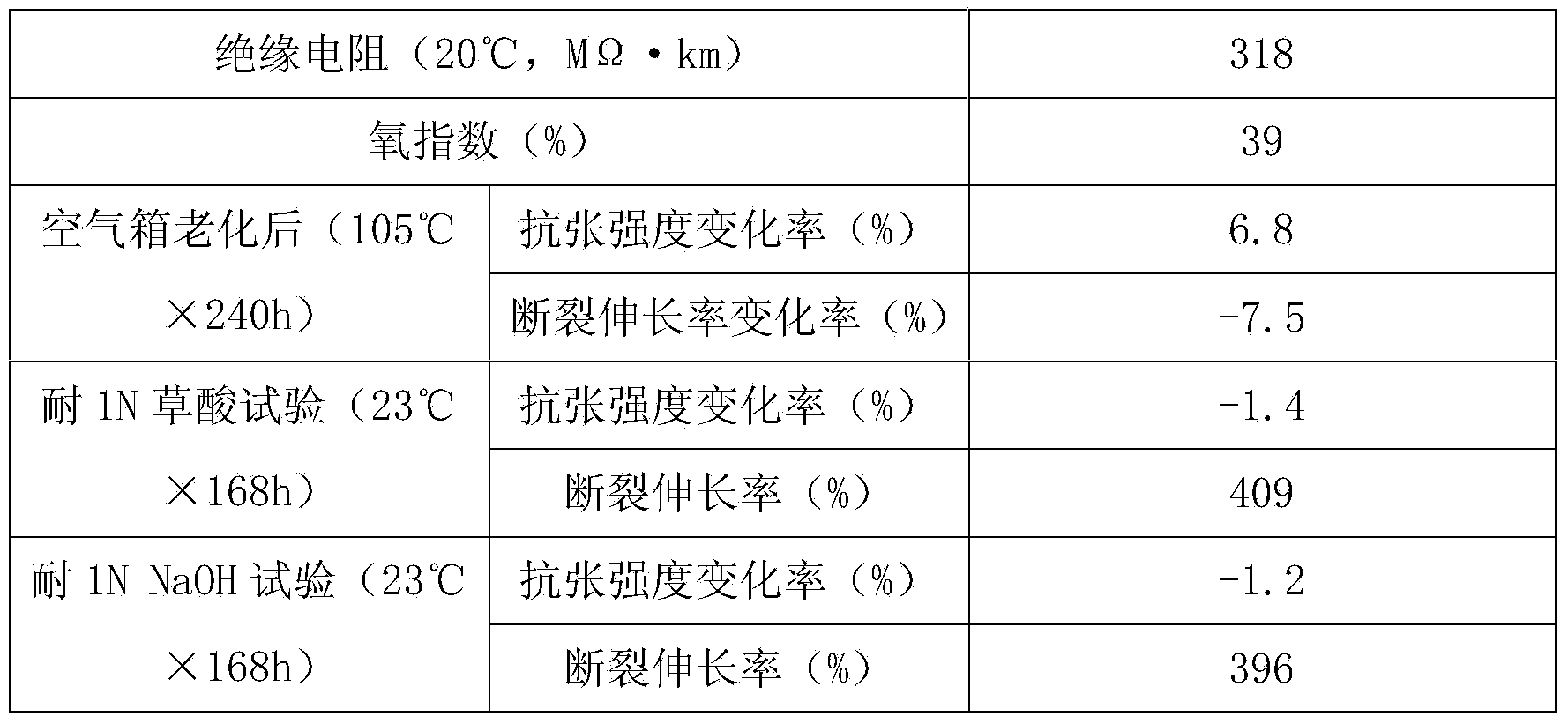

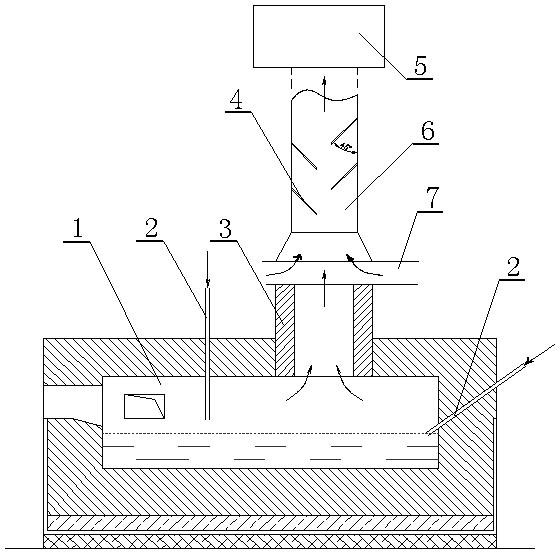

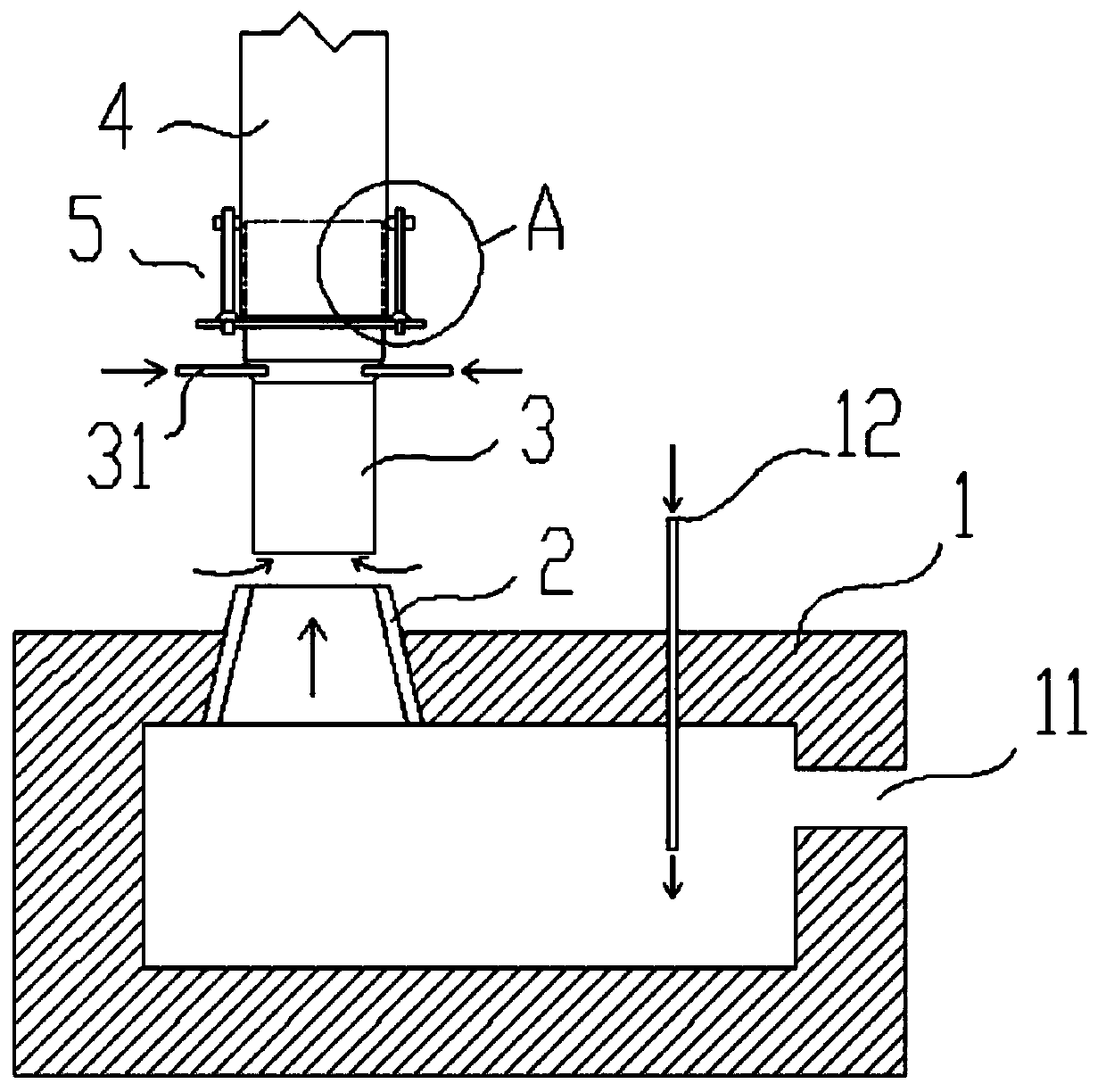

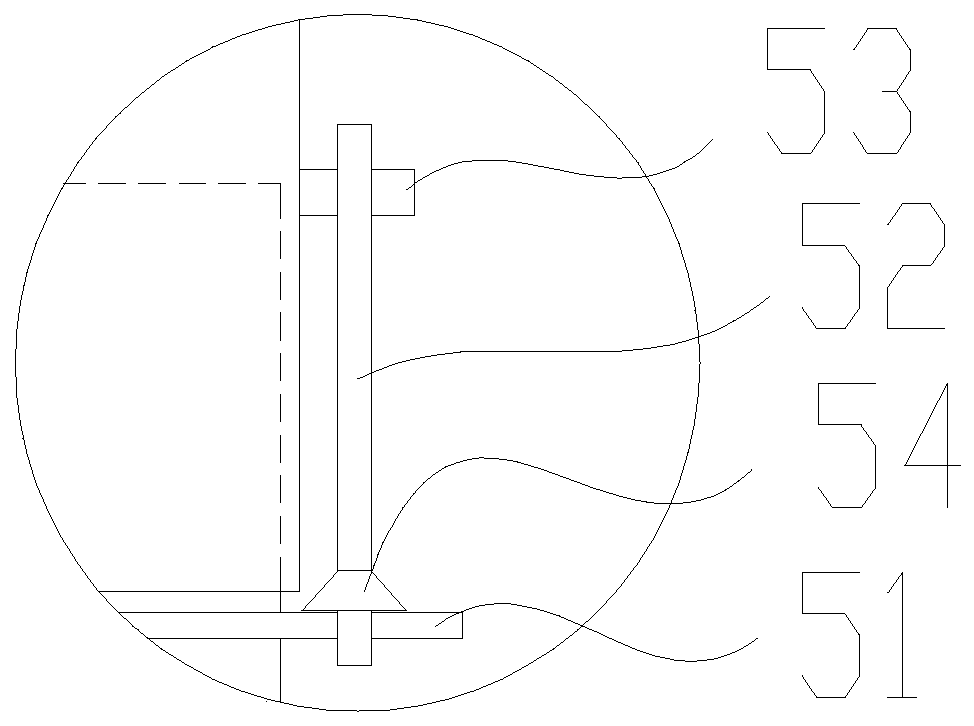

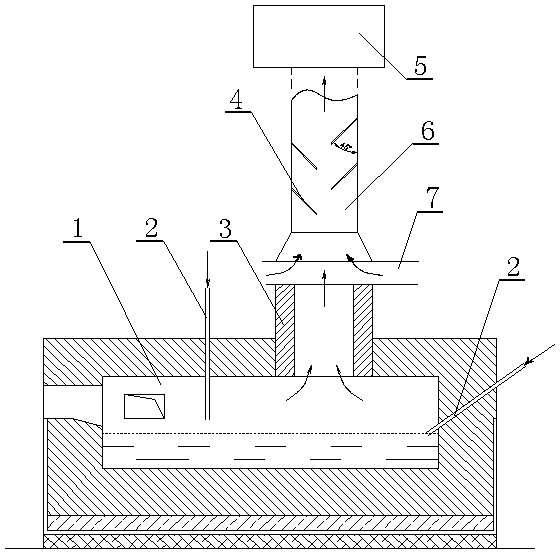

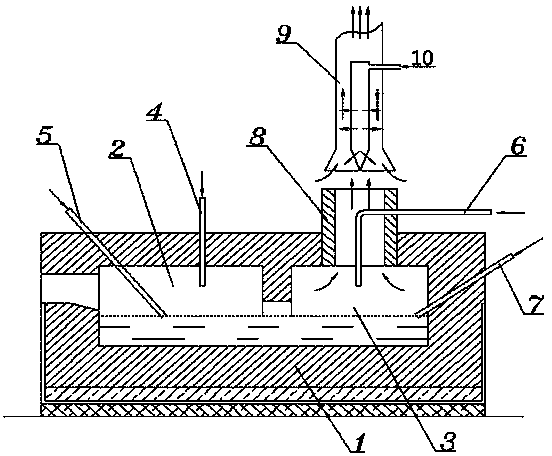

Antimony smelting reverberatory furnace batching device

The invention discloses a proportioning device for an antimony smelting reverberatory furnace. The proportioning device comprises an antimony oxygen bin (1), a vibrator (9), a valve (2), a feed hopper (12), a reverberatory furnace material inlet (13) and the reverberatory furnace (8), wherein a measuring hopper (3) is arranged between the antimony oxygen bin (1) and the feed hopper; two spiral stirrers (5, 6) are arranged below the measuring hopper. The proportioning device for the antimony smelting reverberatory furnace, produced by adopting the method, has the advantages that the proportioning measurement is accurate and the stirring is uniform.

Owner:湖南东港锑品有限公司

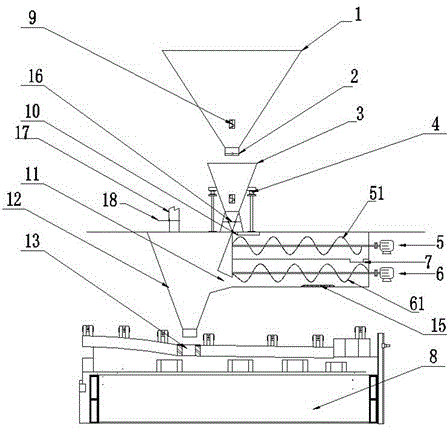

Production device for large-particle-size antimony trioxide

The invention discloses a production device for large-particle-size antimony trioxide. The production device comprises an antimony white furnace (1), an air cooled type reactor (3), a crystallizer (6) and a cooling dust collector (5), wherein the cooling dust collector (5) is communicated with an air outlet above the crystallizer (6). The production device is characterized in that: the crystallizer (6) is a circular multi-baffle crystallizer and is vertically arranged above the air cooled type reactor (3); baffles (4) which are obliquely arranged are arranged in the circular multi-baffle crystallizer (6); the air cooled type reactor (3) is arranged at an air outlet of a hearth of the antimony white furnace (1); and the furnace top and the furnace wall of the antimony white furnace (1) are provided with air pipes (2). The production device provided by the invention has the advantages of simple structure, high productivity, high recovery efficiency and low production cost.

Owner:广西华锑科技有限公司

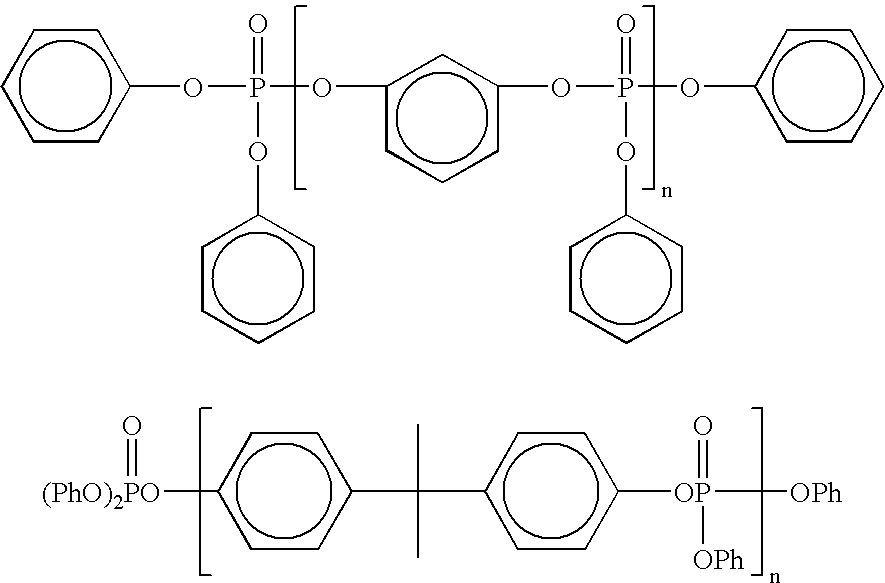

Synthetic resin extrudable composition

The invention relates to a synthetic resin extrudable composition, lacking halogens, which comprises a polycarbonate resin associated with an ABS resin and incorporating phosphate, polysiloxane, fluorinated, zinc and / or antimonium oxide salt and inorganic extender type flame-retardant agents. The composition according to the invention has a high level of fire-resistance corresponding to the I2 classification of the French norm NF-F16.102.

Owner:APARELLAJE ELECTRICO

High-strength and overpressure-resistant submarine cable and preparation method thereof

ActiveCN107200934AExtended service lifeReduce maintenance costsRubber insulatorsPlastic/resin/waxes insulatorsStearateFumed silica

The invention discloses a high-strength and overpressure-resistant submarine cable which is prepared from the following raw materials of ethylene-propylene-diene monomer, nitrile rubber, maleic anhydride grafting ethylene-acetic ether copolymer, butyl stearate, barium stearate, ammonium polyphosphate, ethylene di-stearyl aminebis stearamide, an organic antimonium stabilizer, fumed silica, triethylene glycol di-2-ethylhexoate(triglycol dioctate), an antioxidant DLTP, zinc borate, molybdenum trioxide, medical stone and attapulgite. The invention further discloses a preparation method of the high-strength and overpressure-resistant submarine cable. The submarine cable prepared by the invention has good strength and excellent overpressure resistance and can meet a use requirement of a submarine environment, the service life of the submarine cable is prolonged, maintenance cost of the submarine cable is reduced, and the submarine cable has important market value and social value.

Owner:JIANGXI JIEN HEAVY IND

Antimony metal passivator and bimetal passivator

InactiveCN110252418AImprove stabilityIncrease brightnessCatalytic crackingCatalyst protectionDecompositionPetrochemical

The invention belongs to the field of petrochemical industry and particularly relates to an antimony metal passivator and a bimetal passivator. The antimony metal passivator provided by the invention is prepared according to the following steps: a) mixing citric acid and ethanolamine in water, so as to obtain a mixed solution with a pH value of 4 to 6; and b) subjecting the mixed solution, antimony trioxide and hydrogen peroxide to a hybrid reaction, thereby obtaining the antimony metal passivator. According to the antimony metal passivator, water serves as a dispersion system, citric acid and ethanolamine are adopted as double dispersants, and thus, the stability and transparency of the passivator are improved; and meanwhile, through adjusting a pH value of a reaction system by using the dispersants, the decomposition of hydrogen peroxide of a reaction process is inhibited, and the safety of process is improved. The antimony metal passivator provided by the invention is of homogeneous liquid under normal-temperature conditions and can be dissolved with water at a random ratio, and products are high in stability and easy in storage and use. The preparation of the passivator does not need harsh production conditions such as high temperatures and high pressure, the production process is simple, the cost is relatively low, and no waste gases, waste water and waste residues is produced.

Owner:SHANDONG EFIRM BIOCHEMISTRY & ENVIRONMENTAL PROTECTION CO LTD

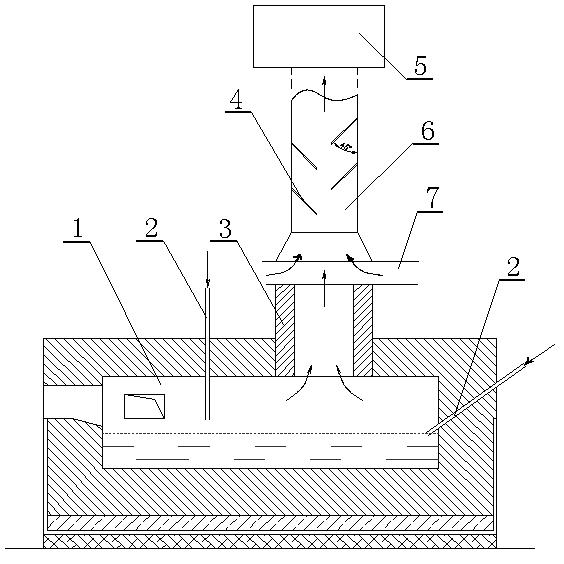

A kind of antimony trioxide powder crystallization system

ActiveCN108622933BAdjustable lengthDwell time is easy to controlAntimony oxides/hydroxides/oxyacidsHeat exchange cooling cystallizationProduction lineFrequency conversion

The invention provides an antimonous oxide powder crystallization system. The antimonous oxide powder crystallization system comprises an antimony white furnace, a reactor, a crystallizer and a powdercollector, wherein the antimony white furnace is provided with an air hose and a feeding opening, a frequency conversion adjustable draught fan is arranged between the reactor and the crystallizer, the crystallizer and the powder collector are connected in a sleeving way and are fixed by using a regulating mechanism, and a low temperature air hose is arranged on the crystallizer. The length of the crystallizer is adjustable, the dwell time of an antimonous oxide material in a crystallization forming section is convenient to control, the crystal form and the grain size of an antimonous oxide power are further controlled, the product specifications of the antimonous oxide are guaranteed to be flexibly regulated on the same production line, the conversion of the crystal form is complete, theproduct quality is further controlled, the low-efficiency investment is avoided, the equipment production line is prevented from being left unused and being wasted, the difficulty in fund flow of theindustry is avoided, and due to the two-section air cooling mode, the whole system reaches rapid quenching, and the product index stably reaches the standard.

Owner:广东宇星阻燃新材股份有限公司

A kind of production method of tellurium selenium copper rod

The invention relates to a production method of a tellurium-selenium copper bar. The tellurium-selenium copper bar comprises the following components of, by mass percent, 0.4-0.7% of tellurium, 0.004-0.012% of phosphorus, 0.1-0.15% of selenium, 0.05-0.1% of sulfur and 0.1-0.15% of antimony, wherein the ratio of the selenium content to the antimony content is 1:1. In addition, the tellurium-selenium copper bar comprises any two elements of silver, titanium, cerium, boron, cobalt, chromium, nickel, niobium and the like, and the content of each of the two arbitrary elements is 0.001-0.005%. The tensile strength of the prepared tellurium-selenium copper bar is greater than 300MPa, the elongation percentage is greater than 15%, and the electric conductivity is greater than 88% IACS.

Owner:徐州鸿誉环境科技有限公司

A kind of high-strength cable material for rail vehicle and preparation method thereof

ActiveCN104017365BHigh mechanical strengthImprove thermal stabilityPlastic/resin/waxes insulatorsGlycidyl methacrylatePhosphine oxide

The invention discloses a high-strength cable material used for a railway vehicle, and a preparation method thereof. The high-strength cable material is prepared from the following raw materials by weight: 85-105 parts of polyphenylene sulfide, 40-60 parts of aromatic polycarbonate, 25-35 parts of ethylene-methyl acrylate-glycidyl methacrylate terpolymer, 4-8 parts of diphenyl-methane-diisocyanate, 12-16 parts of bis(4-carboxyphenyl)phenyl-phosphine oxide, 10-15 parts of zinc aluminate, 20-30 parts of magnesium hydroxide,8-12 parts of basalt short fibers, 2-3 parts of methacryloyloxy propyltrimethoxysilane, 3-5 parts of tri-(stearic mercaptoacetate)antimonium, 2-3 parts of calcium stearate, 1.5-2.5 parts of barium stearate, 4-8 parts of erucyl amide, 3-6 parts of polyethylene wax, 15-20 parts of calcined clay, 10-15 parts of basic magnesium chloride whiskers, 20-30 parts of precipitated white carbon black, 14-18 parts of modified stone powder, 10-15 parts of epoxidized methyl acetorieinoleate and 2-3 parts of an antioxidant 1222. The cable material provided by the invention has the advantages of high mechanical strength, high flame retardance, fire resistance, good thermal stability, excellent electrical insulation property, wide usage temperature range, etc.

Owner:ANHUI KANGLIYA CO LTD

Production device for large-particle-size antimony trioxide

The invention discloses a production device for large-particle-size antimony trioxide. The production device comprises an antimony white furnace (1), an air cooled type reactor (3), a crystallizer (6) and a cooling dust collector (5), wherein the cooling dust collector (5) is communicated with an air outlet above the crystallizer (6). The production device is characterized in that: the crystallizer (6) is a circular multi-baffle crystallizer and is vertically arranged above the air cooled type reactor (3); baffles (4) which are obliquely arranged are arranged in the circular multi-baffle crystallizer (6); the air cooled type reactor (3) is arranged at an air outlet of a hearth of the antimony white furnace (1); and the furnace top and the furnace wall of the antimony white furnace (1) are provided with air pipes (2). The production device provided by the invention has the advantages of simple structure, high productivity, high recovery efficiency and low production cost.

Owner:广西华锑科技有限公司

High tellurium copper slag treatment method

ActiveCN107201448BHigh recovery rateAchieve the purpose of separationElectrolysis componentsProcess efficiency improvementSorghumBismuth

The invention discloses a high-tellurium copper slag treatment method. The high-tellurium copper slag treatment method comprises the following steps of: (1) ball-milling; (2) acidifying; (3) low-acid leaching; (4) bismuth precipitating; (5) copper precipitating; (6) high-acid pickling; (7) gold, sliver and lead recycling; (8) solution replacing; (9) antimonium precipitating; (10) tellurium leaching; (11) purifying; (12) neutralizing and tellurium precipitating; and (13) electrolyzing and tellurium extracting. The method disclosed by the invention can be adopted to clean and efficiently treat copper slag, comprehensively recycles noble metals such as gold, silver, tellurium, antimonium, bismuth and copper, and radically solves the problems such as a lagged process, poor comprehensive utilization, a low metal recovery rate and severe environmental pollution of the conventional method.

Owner:HUNAN RONGPENG ENVIRONMENTAL PROTECTION TECH CO LTD

Process for synthesizing organometallic antimonide

InactiveCN1891708BAvoid disproportionationImprove conversion rateAntimony organic compoundsPolyesterSolubility

This invention discloses a new synthesis technology of diatomic alcohol antimonium of organic antimonide used for polyester polycondensation. The technology uses antimonious material and diatomic alcohol to synthesize diatomic alcohol antimonium in the presence of reducing substances through reaction, filtration, crystallization and drying. The material combined with good solubility, high purity,high catalytic activity and the advantages of color, and the excessive alcohol can be recycled.

Owner:李绍通

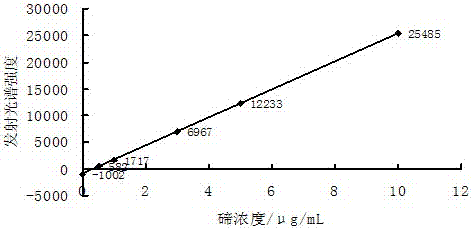

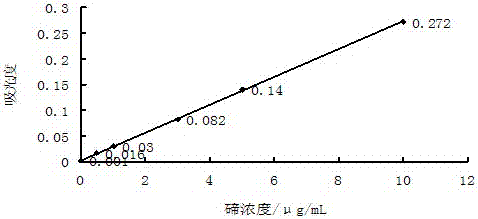

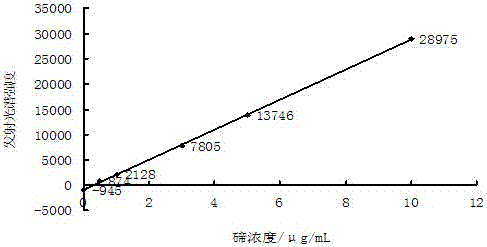

Determination method of tellurium content in antimony and antimony trioxide

ActiveCN104034668BFast measurementSimple and fast operationPreparing sample for investigationColor/spectral properties measurementsTe elementAntimony trioxide

The invention relates to a method for measuring the content of tellurium in antimony and antimonous oxide. The method comprises the steps of dissolving antimony through chloroazotic acid or dissolving antimonous oxide through hydrochloric acid, then adding sulfuric acid and hydrobromic acid for volatilizing antimony under the temperature of 200-340 DEG C, repeatedly adding hydrochloric acid and bromic acid, heating under low temperature to volatilize and remove antimony, adding hydrochloric acid to dissolve residues, and performing dilution to make up to the volume; measuring a standard tellurium solution through an electric inductance coupling plasma emission spectrometer or a flame atom absorption spectrometer and drawing a working curve, then measuring the emission spectrum intensity or the absorbancy of an impurity, namely tellurium in a test sample, and constructing methods for analyzing tellurium in antimony and antimonous oxide in sequence according to a linear relation between concentration of tellurium and the emission spectrum intensity or the absorbancy in a certain concentration range; and calculating the concentration of tellurium in test liquid according to the working curve of the measured standard tellurium solution, and further calculating the mass percentage of tellurium. The method disclosed by the invention has the advantages of high sensitivity, high precision, high accuracy, wide linear range, high analysis efficiency and the like.

Owner:锡矿山闪星锑业有限责任公司

Processing process of tellurium-selenium-copper rod

The invention relates to a processing process of a tellurium-selenium-copper rod. The tellurium-selenium-copper rod comprises the following components in percentage by mass: 0.4-0.7% of tellurium, 0.004-0.012% of phosphorus, 0.1-0.15% of selenium, 0.05-0.1% of sulphur and 0.1-0.15% of antimony, wherein the ratio of the selenium content to the antimony content is 1:1; the tellurium-selenium-copper rod further comprises any two of the following elements: silver, titanium, cerium, boron, cobalt, chromium, nickel and niobium; and the content of each of the any two elements is 0.001-0.005%. The processing process of the tellurium-selenium-copper rod comprises the following steps: performing upward continuous casting on the tellurium-selenium-copper rod, milling, performing continuous rolling and annealing, drawing, straightening, slitting and the like.

Owner:四川孚孚新材料科技有限公司

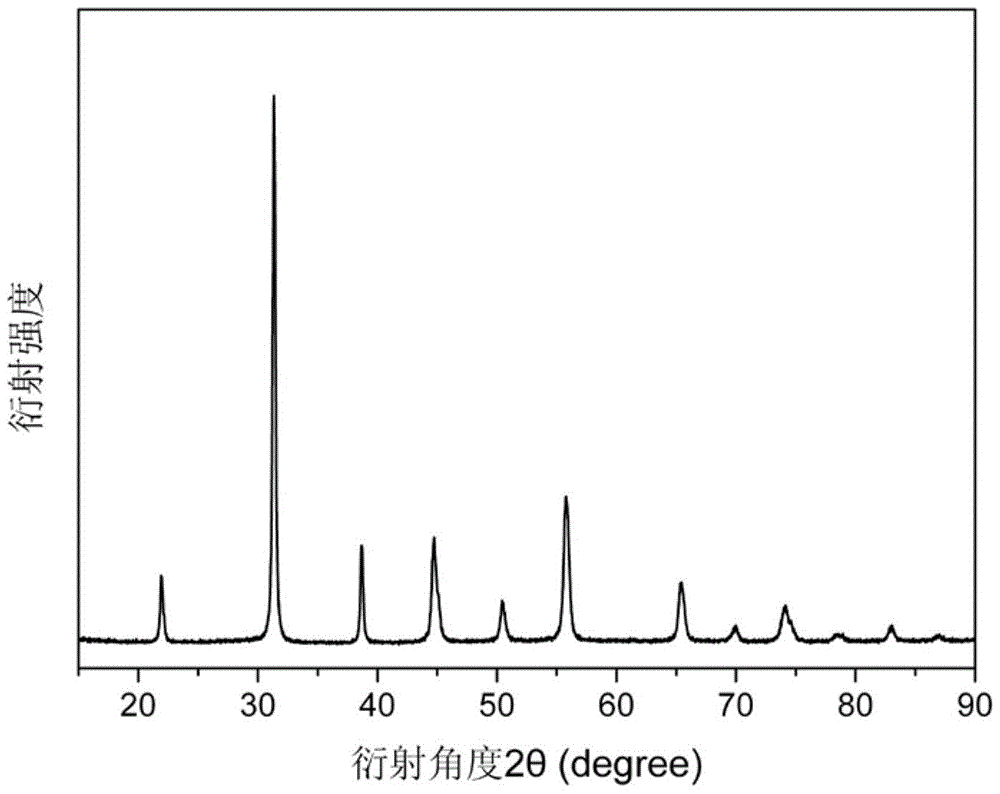

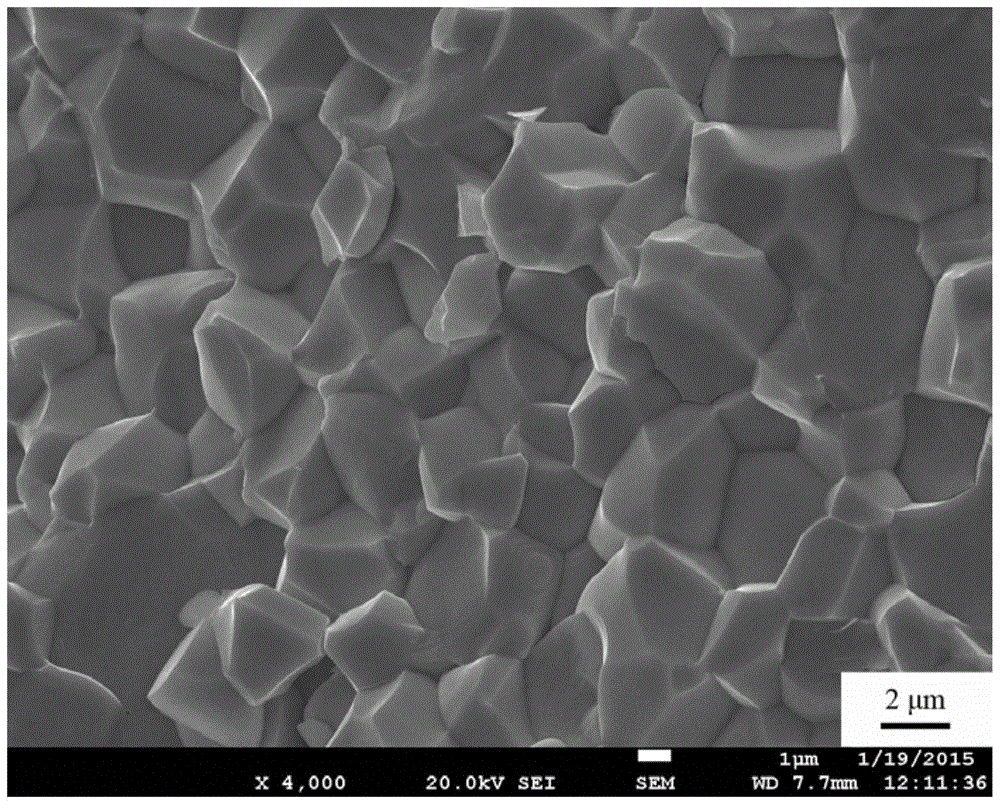

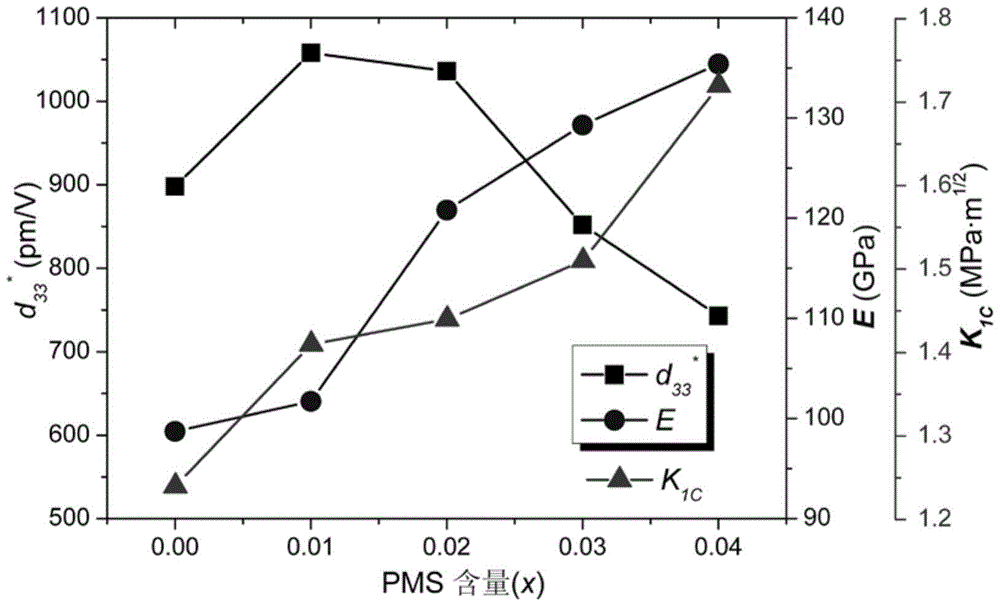

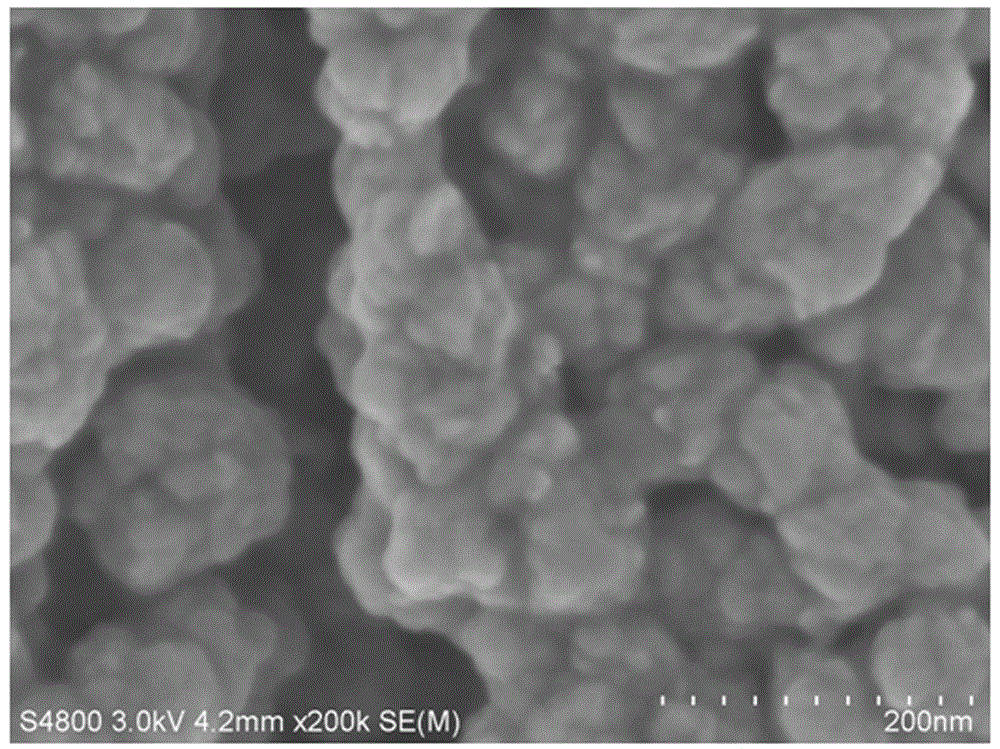

A niobium-nickel-lead zirconate titanate piezoelectric ceramic doped with manganese lead antimonate

ActiveCN104844202BHigh piezoelectric coefficientImprove mechanical propertiesPiezoelectric/electrostrictive/magnetostrictive devicesLead zirconate titanateNiobium

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

Method for producing free-cut conductive sulfur-copper bar

The invention relates to a method for producing a free-cut conductive sulfur-copper bar. A copper bar comprises the following chemical components in percentage by weight: 0.2-0.5% of sulfur, 0.002-0.005% of phosphorus, 0.1-0.15% of selenium and 0.1-0.15% of antimony, wherein the ratio of selenium to antimony is 1:1; the tensile strength of the copper bar is greater than 320MPa; the ductility of the copper bar is greater than 5%; the conductivity of the copper bar is greater than 82% IACS (International Annealed Copper Standard); and the cutting rate of the copper bar is over 82% that of free-cut brass (of which the copper content is 61%, the zinc content is 36% and the lead content is 3%).

Owner:HESHAN JINZHOU COPPER IND

Method for preparing tin antimony oxide conductive nano material

The invention belongs to the technical field of preparation of functional materials, and relates to a method for preparing a tin antimony oxide conductive nano material. A methanol solution of a stannous chloride and antimony butter mixture is dropwise added into an oxalic acid water solution, reacting is carried out under the conditions of constant temperature and stirring till precursor sediment is generated, and filtering, washing and drying are carried out; then thermal temperature is carried out in a muffle furnace, and the tin antimony oxide conductive nano material is obtained. The process is simple and easy to carry out, the purity is high, the impurity content is low, the product preparation cost is low, performance is excellent, and industrial mass production can be achieved. The prepared tin antimony oxide conductive nano material has good conductivity, heat insulation performance, transparency and other performance, and can be applied to plastic, transparent coatings and various kinds of resin to achieve the functions of achieving transparency, insulating heat, preventing static and the like.

Owner:BOHAI UNIV

Preparation device for catalyst-grade antimonous oxide

Owner:广西华锑科技有限公司

A kind of method of producing sodium antimonate with antimony oxide

InactiveCN106277052BPromote conversionIncrease profitAntimonates/antimonitesReaction temperatureRoom temperature

The invention relates to a method using antimony oxide to produce sodium antimonate. The method includes: heating the antimony oxide for 20 minutes, adding into a reactor container, adding hydrochloric acid and water, adding sodium polyacrylate while stirring, adding sodium hydroxide into the reaction container, continuing stirring, controlling reaction temperature to be 50-60 DEG C to perform reaction for 30-40 minutes, and feeding oxygen into the reaction container; slowly adding hydrogen peroxide, controlling reaction temperature to be 40-50 DEG C, and continuing performing reaction for 10 minutes after the adding of the hydrogen peroxide is completed in 30-50 minutes, and stopping stirring; standing, cooling to room temperature to filter out precipitates, washing the precipitates with water, and drying the washed precipitates until the moisture of the precipitates is smaller than 0.3% to obtain the sodium antimonate. By the method, the conversion of the antimony oxide during reaction is promoted, conversion rate is increased, and accordingly the production efficiency of the sodium antimonate is increased, raw material utilization rate is increased, the production time of the sodium antimonate is lowered effectively, and raw material use amount is reduced.

Owner:陈安民

Solder alloy, solder paste, and electronic circuit board

ActiveUS20180311773A1Low melting pointLow costWelding/cutting media/materialsPrinted circuitsIndiumMass ratio

In a solder alloy consisting essentially of tin, silver, copper, bismuth, antimony, indium, and nickel, the content ratio of the silver is 0.05 mass % or more and below 0.2 mass %; the content ratio of the copper is 0.1 mass % or more and 1 mass % or less; the content ratio of the bismuth is above 4.0 mass % and 10 mass % or less; the content ratio of the antimony is 0.005 mass % or more and 8 mass % or less; the content ratio of the indium is 0.005 mass % or more and 2 mass % or less; the content ratio of the nickel is 0.003 mass % or more and 0.4 mass % or less; and the content ratio of the tin is the remaining ratio and the mass ratio (Bi / Ni) of the bismuth content with respect to the nickel content is 35 or more and 1500 or less.

Owner:HARIMA CHEM INC

A kind of antimony ingot feeding method for antimony smelting

ActiveCN105821220BReduce labor intensityAvoid affecting the workshop environmentCharge manipulationFurnace temperatureIngot

The invention provides an antimony ingot feeding method of antimony smelting. An antimony ingot temperature-resistant material collection hopper is installed on an antimony metallurgical furnace. Antimony ingots are arranged in the temperature-resistant material collection hopper, move downwards in the temperature-resistant material collection hopper under the effect of gravity, and fall on a heated material melting table arranged at the bottom of the interior of the furnace. Melt in the furnace slowly melts the bulk antimony ingots, and molten antimony liquid flows downwards to effectively supplement molten liquid in the furnace so that the molten liquid can be kept at a certain liquid level for a long time. By means of the antimony ingot feeding method of antimony smelting, raw materials do not need to be input regularly and quantitatively in the production process; and in this way, the labor intensity of operators can be lowered, and meanwhile the production efficiency can be improved. In addition, it can be avoided that because excessively-large furnace temperature fluctuation is caused by human factors in the production process and especially workshop environments are influenced by high-temperature melt splashing, smoking and the like when workers conduct throwing, the production condition in the furnace is not stable and the product quality is influenced.

Owner:YIYANG SHENGLI CHEM IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com