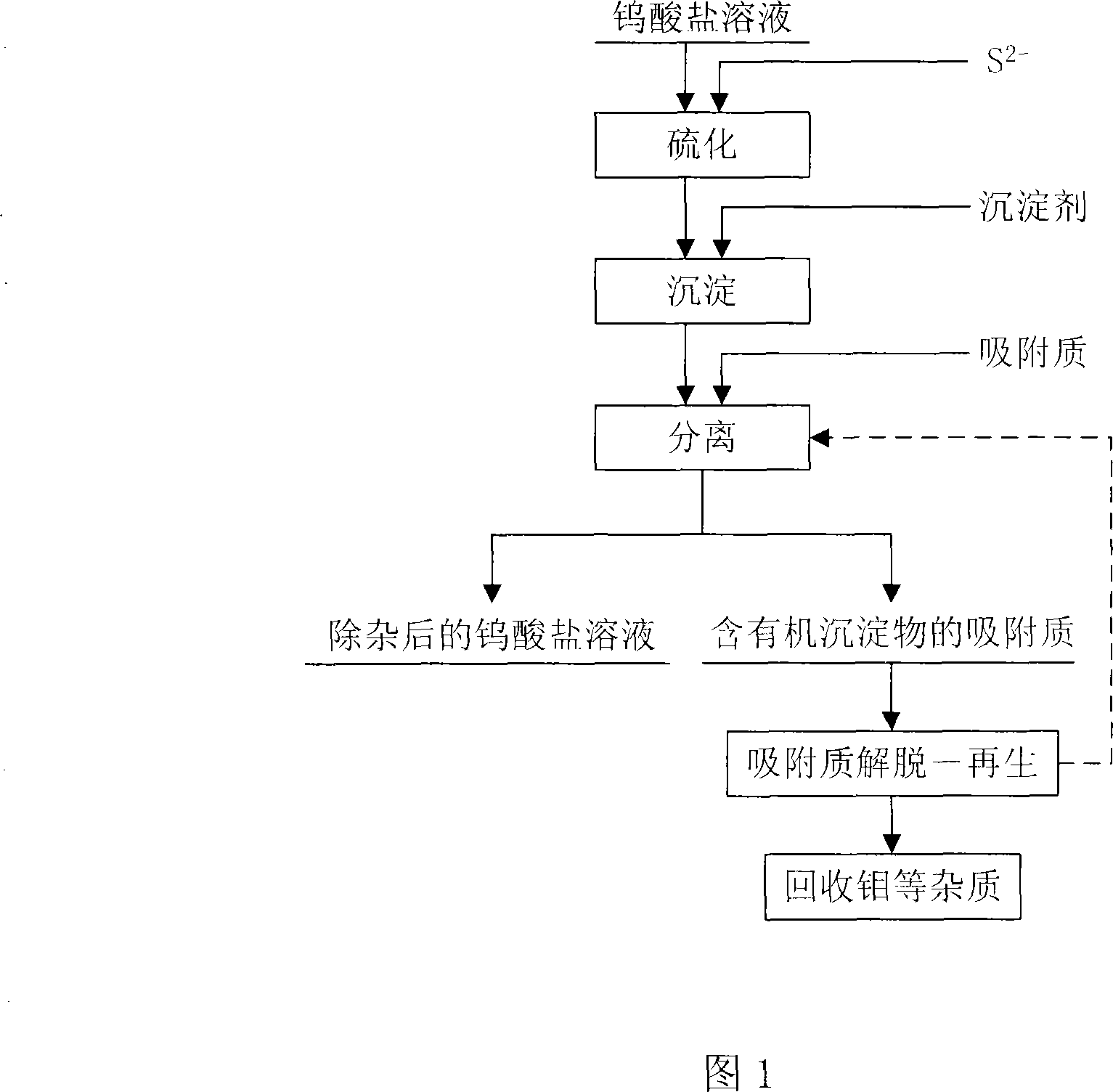

Method for removing molybdenum, arsenic, antimony and stannum from tungstate solution

A tungstate and solution technology, which is applied in the field of tungsten smelting, can solve the problems of large tungsten loss and pollution, and achieve the effects of low production cost, simple equipment and short process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Get ammonium tungstate solution 100ml, wherein WO 3 220g / l, Mo 1.70g / l. First, during vulcanization, S 2- The amount of addition is calculated as an excess of 3.5g / l to add Na 2 S, vulcanized at 20°C for 24 hours; followed by adding the precipitant octadecyltrimethylammonium bromide, the addition amount is 0.9 times of the theoretical amount, that is, the organic precipitant dissolved in pure water is added to the tungstic acid at 20°C ammonium solution and stirred for 1.5 hours; finally, 15 g of fragmented activated carbon fibers were added and stirred for 0.5 hours, and filtered after standing for 0.5 hours. The filtered ammonium tungstate solution contains Mo 0.05g / l, and the molybdenum removal rate is 95.1%. The activated carbon fiber contains W<20ppm after being washed twice with pure water.

Embodiment 2

[0022] Get ammonium tungstate solution 100ml, wherein WO 3 120g / l, Mo 0.25g / l. During vulcanization, S 2- According to the calculation, add Na in excess of 3.0g / l 2 S; Add dodecyltrimethylammonium chloride after vulcanization at 20°C for 24 hours, and the amount of precipitant added is 5 times the theoretical amount, that is, the organic precipitant dissolved in pure water is added to tungsten at 20°C The ammonium acid solution was stirred for 2.0 hours; then 15 g of activated carbon was added and stirred for 0.5 hours, after filtration, the filtrate contained Mo 0.002 g / l, and the molybdenum removal rate was 99.0%.

Embodiment 3

[0024] Get sodium tungstate solution 100ml, wherein WO 3 80g / l, Mo 2.0g / l. The vulcanization is carried out under the condition of sodium tungstate solution pH=7.0, during vulcanization, S 2- The amount of addition is based on the calculation of an excess of 2.6g / l by adding Na 2 S; after vulcanization at 70°C for 2.0 hours, add cetyltrimethylammonium chloride and stir for 0.5 hours, the amount of precipitant added is 3 times the theoretical amount; after standing for 0.5 hours, filter and separate the filtrate Containing Mo 0.1g / l, molybdenum removal rate is 93.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com