Method for preparing tin antimony oxide conductive nano material

A technology of conductive nanometer and tin antimony oxide, which is applied in the direction of tin oxide, etc., can solve the problems of high equipment requirements, low purity, and difficult control of crystal shape, and achieve the effects of low preparation cost, high production efficiency, and easy operation control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

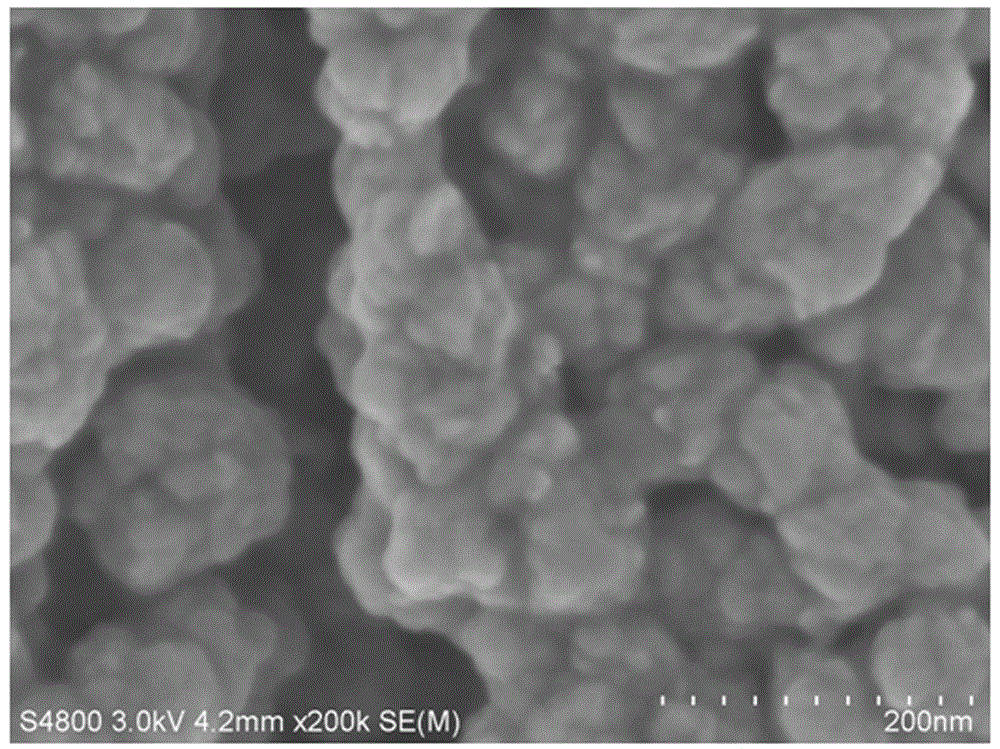

[0034] Under the conditions of a constant temperature of 20°C and a stirring speed of 150 rpm, the methanol solution of the mixture of antimony trichloride and stannous chloride was added dropwise to the aqueous oxalic acid solution. The molar concentration of stannous chloride methanol solution is 0.5 mol / L, and the molar concentration of oxalic acid is 0.5 mol / L. The molar ratio of stannous chloride, antimony trichloride and oxalic acid is 1:1:50 in turn. The speed of dripping antimony trichloride and stannous chloride methanol solution is 180 drops / min, and the stirring reaction time is 10 minutes. After the reaction finishes, filter and wash and dry. The drying time is 3 hours, and the drying temperature is 80°C. The heating rate was 10 °C / min. Calcination was then carried out in a muffle furnace at a calcination temperature of 400 °C, a calcination time of 5 h, and a heating rate of 10 °C / min. After natural cooling, the target product is obtained. The particle size of ...

Embodiment 2

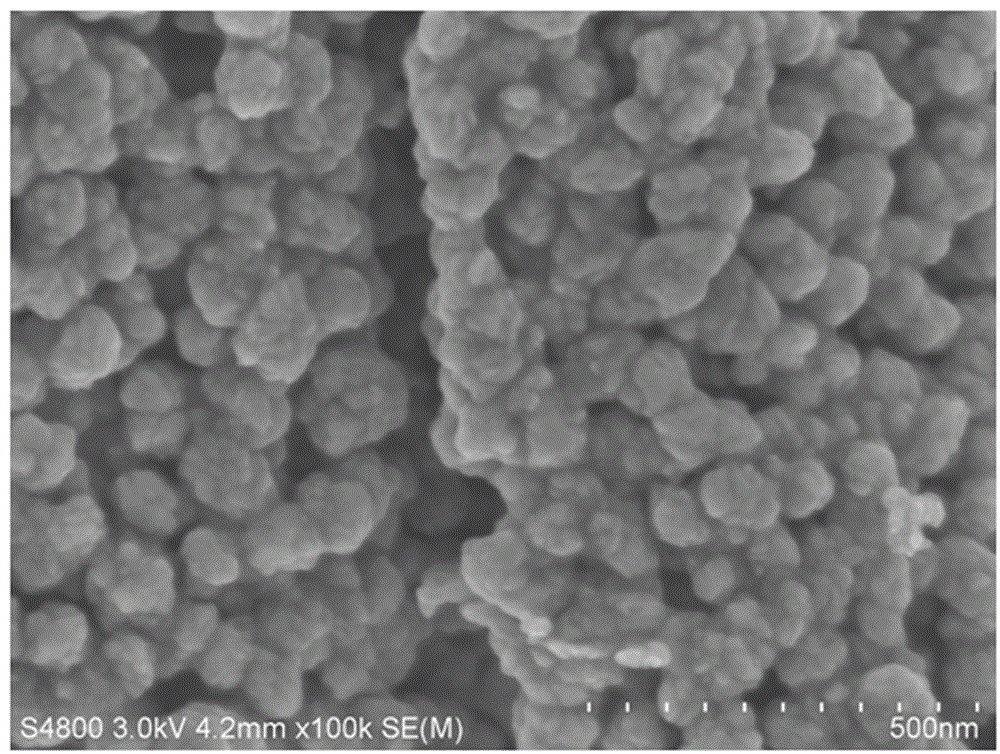

[0036] Under the conditions of a constant temperature of 30°C and a stirring speed of 100 rpm, the methanol solution of the mixture of antimony trichloride and stannous chloride was added dropwise to the aqueous oxalic acid solution. The molar concentration of stannous chloride methanol solution is 0.1 mol / L, and the molar concentration of oxalic acid is 0.5 mol / L. The molar ratio of stannous chloride, antimony trichloride and oxalic acid is 1:0.5:10 in turn. The speed of dripping antimony trichloride and stannous chloride methanol solution is 180 drops / min, and the stirring reaction time is 10 minutes. After the reaction finishes, filter and wash and dry. The drying time is 3 hours, and the drying temperature is 80°C. The heating rate was 10 °C / min. Calcination was then carried out in a muffle furnace at a calcination temperature of 800 °C, a calcination time of 2 h, and a heating rate of 10 °C / min. After natural cooling, the target product is obtained. The particle size o...

Embodiment 3

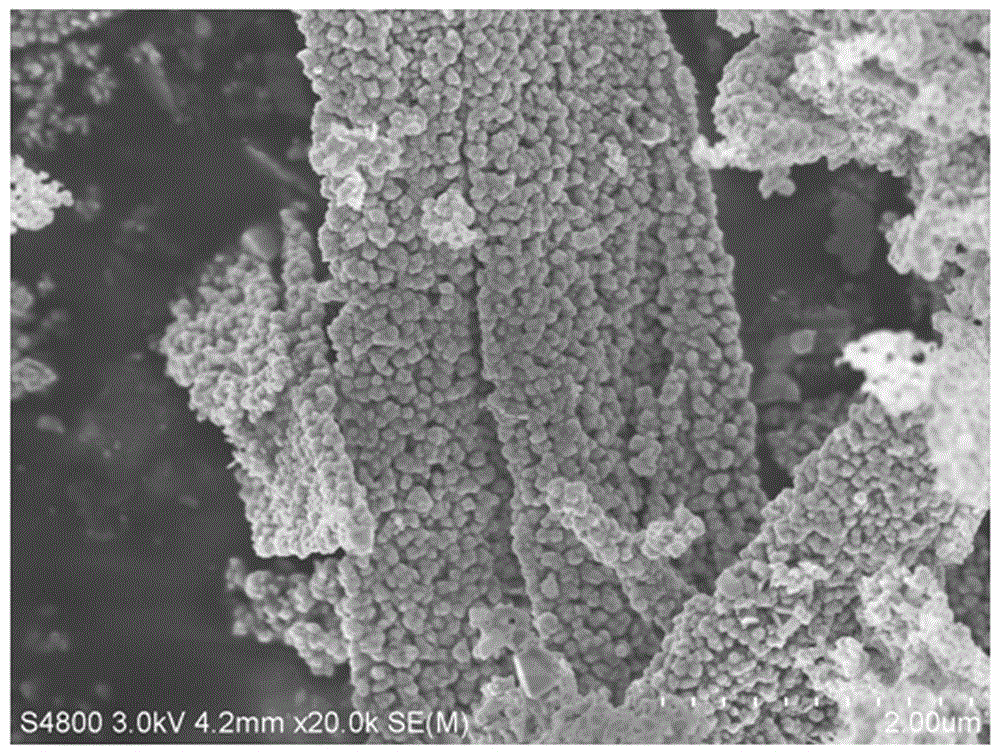

[0038] Under the conditions of a constant temperature of 30°C and a stirring speed of 100 rpm, the methanol solution of the mixture of antimony trichloride and stannous chloride was added dropwise to the aqueous oxalic acid solution. The molar concentration of stannous chloride methanol solution is 0.2 mol / L, and the molar concentration of oxalic acid is 0.5 mol / L. The molar ratio of stannous chloride, antimony trichloride and oxalic acid is 1:2:20 in turn. The speed of dripping antimony trichloride and stannous chloride methanol solution is 180 drops / min, and the stirring reaction time is 10 minutes. After the reaction finishes, filter and wash and dry. The drying time is 3 hours, and the drying temperature is 80°C. The heating rate was 10 °C / min. Calcination was then carried out in a muffle furnace at a calcination temperature of 600 °C, a calcination time of 3 h, and a heating rate of 20 °C / min. After natural cooling, the target product is obtained. The particle size of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com