High-strength and overpressure-resistant submarine cable and preparation method thereof

A submarine cable, high-strength technology, applied in circuits, electrical components, plastic/resin/wax insulators, etc., can solve the complex laying environment, prone to aging, submarine cable strength and voltage resistance can not meet the needs of the market and other problems , to achieve the effect of reducing maintenance costs, extending service life, important market value and social value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

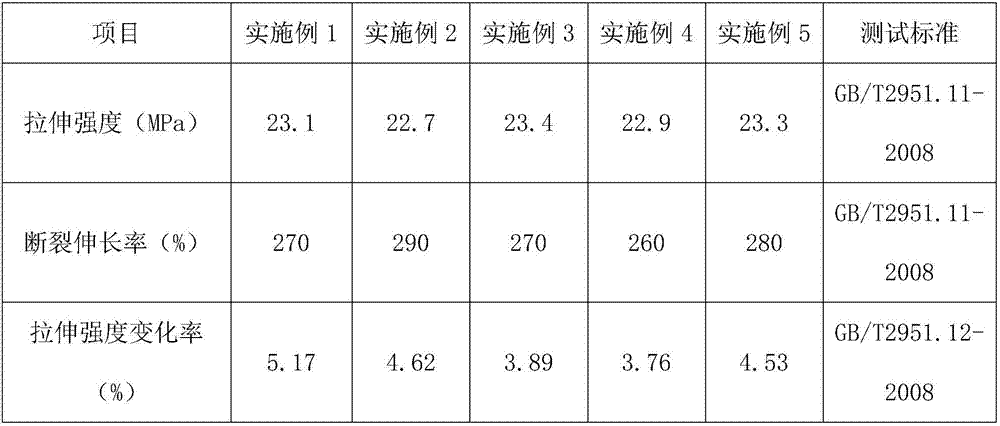

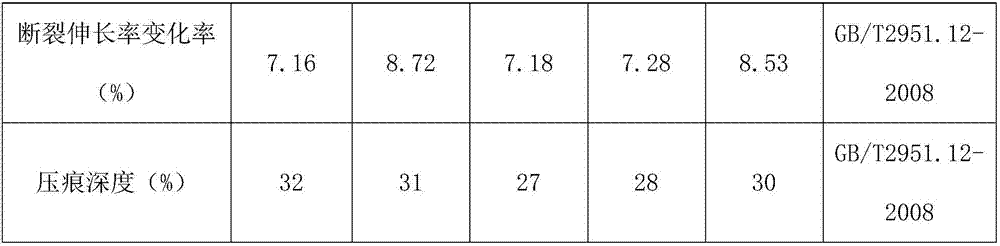

Examples

Embodiment 1

[0019] A high-strength and pressure-resistant submarine cable material is made of the following raw materials in parts by weight: 85 parts of EPDM rubber, 17 parts of nitrile rubber, and 12 parts of maleic anhydride grafted ethylene-ethyl acetate copolymer , 3 parts of butyl stearate, 1 part of barium stearate, 6 parts of ammonium polyphosphate, 2 parts of ethylene distearic acid amine, 2 parts of organic antimony stabilizer, 3 parts of fumed white carbon black, triethylene glycol diethylene glycol 3 parts of isooctanoate, 1 part of antioxidant DLTP, 3 parts of zinc borate, 2 parts of molybdenum trioxide, 4 parts of medical stone, 8 parts of attapulgite.

[0020] In this embodiment, the preparation method of the high-strength and pressure-resistant submarine cable material has the following steps:

[0021] 1) Weigh molybdenum trioxide, medical stone and attapulgite, pulverize, pass through an 80-mesh sieve, combine, and calcinate at 620°C for 2 hours to obtain calcined materia...

Embodiment 2

[0027] A high-strength and pressure-resistant submarine cable material, made of the following raw materials in parts by weight: EPDM rubber 86 parts, nitrile rubber 18 parts, maleic anhydride grafted ethylene-ethyl acetate copolymer 13 parts , 4.7 parts of butyl stearate, 1.8 parts of barium stearate, 8 parts of ammonium polyphosphate, 2.4 parts of ethylene distearic acid amine, 3 parts of organic antimony stabilizer, 3.1 parts of fumed white carbon black, triethylene glycol diethylene glycol 4.5 parts of isooctanoate, 1.7 parts of antioxidant DLTP, 3.7 parts of zinc borate, 2.2 parts of molybdenum trioxide, 5 parts of medical stone, 9.5 parts of attapulgite.

[0028] In this embodiment, the preparation method of the high-strength and pressure-resistant submarine cable material has the following steps:

[0029] 1) Weigh molybdenum trioxide, medical stone and attapulgite, pulverize, pass through an 80-mesh sieve, combine, and calcinate at 630° C. for 2.5 hours to obtain calcine...

Embodiment 3

[0035] A high-strength and pressure-resistant submarine cable material is made of the following raw materials in parts by weight: EPDM rubber 87 parts, nitrile rubber 19 parts, maleic anhydride grafted ethylene-ethyl acetate copolymer 13 parts , 3.9 parts of butyl stearate, 1.6 parts of barium stearate, 7.5 parts of ammonium polyphosphate, 2.6 parts of ethylene bisstearic acid amine, 3.5 parts of organic antimony stabilizer, 3.3 parts of fumed white carbon black, triethylene glycol diethylene glycol 4 parts of isooctanoate, 1.5 parts of antioxidant DLTP, 3.6 parts of zinc borate, 2.4 parts of molybdenum trioxide, 5.5 parts of medical stone, 9 parts of attapulgite.

[0036] In this embodiment, the preparation method of the high-strength and pressure-resistant submarine cable material has the following steps:

[0037] 1) Weigh molybdenum trioxide, medical stone and attapulgite, pulverize, pass through a 90-mesh sieve, combine, and calcinate at 635° C. for 2.5 hours to obtain cal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com