Preparation device for catalyst-grade antimonous oxide

A technology for preparing antimony trioxide and a device, which is applied in the direction of inorganic chemistry, antimony compounds, chemical instruments and methods, etc., can solve the problems of high production capacity consumption, insufficient purity of antimony trioxide, etc., and achieve cost saving, simple structure, highly active effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

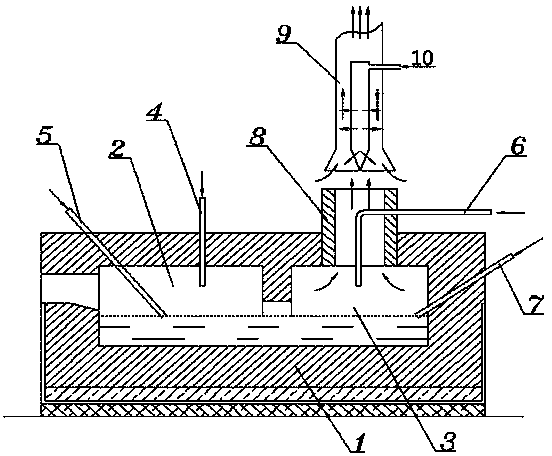

[0025] Using 300g metal antimony as raw material, raise the temperature of antimony white furnace 1 to 1000°C, put metal antimony into the front chamber 2 of antimony white furnace 1 to melt it, and blow air to the top blowing pipe a4 and side of the front chamber 2 The pipe a5 blows into a top blower and a side blower respectively to oxidize and volatilize the antimony to form antimony trioxide furnace gas; guide the antimony trioxide furnace gas into the breech 3, and blow it to the top blower pipe b6 and the side of the breech 3 The blowing pipe b7 blows into the secondary top blowing and the secondary side blowing respectively, so that the furnace gas continues to contact oxygen; after the temperature of the antimony white furnace 1 gas is further raised to 1200 ° C, the antimony trioxide furnace gas is introduced into the reactor 8, And keep the temperature of the reactor 8 stable; Finally, the high-temperature antimony oxide furnace gas is introduced into the annular jet ...

Embodiment 2

[0027] Using 50 kilograms of metal antimony as raw material, raise the temperature of the antimony white furnace 1 to 1000°C, put metal antimony into the front chamber 2 of the antimony white furnace 1 to melt it, and blow the top blowing pipe a4 and the side of the front chamber 2 Blowing pipe a5 blows into a top blowing and a side blowing respectively to oxidize and volatilize the antimony to form antimony trioxide furnace gas; guide the antimony trioxide furnace gas into the breech 3 and send it to the top blowing pipe b6 and the breech 3 The side blowing pipe b7 blows into the secondary top blowing and secondary side blowing respectively, so that the furnace gas continues to contact oxygen; after the temperature of the antimony white furnace 1 gas is further raised to 1300 ° C, the antimony trioxide furnace gas is introduced into the reactor 8 , and keep the temperature of the reactor 8 stable; finally, the high-temperature antimony oxide furnace gas is introduced into the ...

Embodiment 3

[0029] Using 20 kg of metal antimony as raw material, raise the temperature of antimony white furnace 1 to 1000°C, put metal antimony into the front chamber 2 of antimony white furnace 1 to melt it, and blow the top blowing pipe a4 and the side of the front chamber 2 Blowing pipe a5 blows into a top blowing and a side blowing respectively to oxidize and volatilize the antimony to form antimony trioxide furnace gas; guide the antimony trioxide furnace gas into the breech 3 and send it to the top blowing pipe b6 and the breech 3 The side blowing pipe b7 blows into the secondary top blowing and the secondary side blowing respectively, so that the furnace gas continues to contact oxygen; after the temperature of the antimony white furnace 1 gas is further raised to 1250 ° C, the antimony trioxide furnace gas is introduced into the reactor 8 , and keep the temperature of the reactor 8 stable; finally, the high-temperature antimony oxide furnace gas is introduced into the annular jet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com