Production device for large-particle-size antimony trioxide

A technology of antimony trioxide and production equipment, which is applied in the direction of inorganic chemistry, antimony compounds, chemical instruments and methods, etc., can solve the problems of many production processes, complex equipment, low direct yield, etc., and achieve the improvement of production efficiency, temperature field evenly distributed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

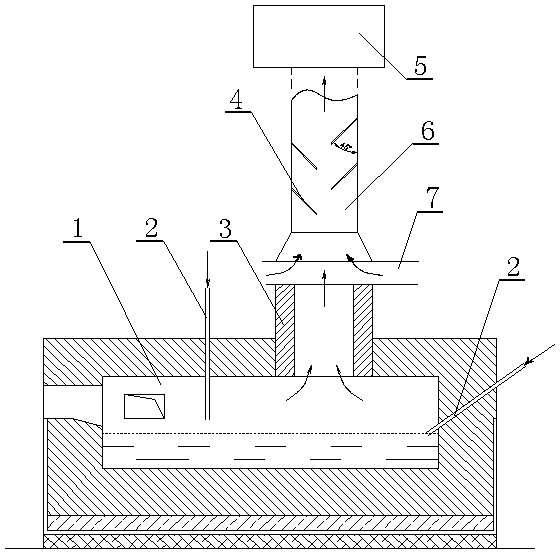

[0016] As shown in the accompanying drawing, the production device of large-diameter antimony trioxide includes an antimony white furnace 1, an air-cooled reactor 3, a crystallizer 6 and a cooling dust collector 5, and the combination of the cooling dust collector 5 and the crystallizer 6 The upper air outlet is connected; the crystallizer 6 is a circular multi-baffle crystallizer, and is vertically installed above the air-cooled reactor 3, and the circular multi-baffle crystallizer 6 is provided with obliquely installed baffles 4. The installation slope of the baffle plate 4 is 45°, and the installation method is dislocation and diagonal installation; the air-cooled reactor 3 is installed at the gas outlet of the hearth of the antimony white furnace 1; the furnace top of the antimony white furnace 1 One air duct 2 is installed on the furnace wall, and four air ducts 2 are installed on the furnace wall. One end of the air duct 2 is connected to the blower, and the other end ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com