Production method of large-particle-size antimonous oxide

A technology of antimony trioxide and production methods, which is applied in chemical instruments and methods, inorganic chemistry, antimony compounds, etc. It can solve the problems of large-grained crystals, easy deposition at the bottom of pipelines, and failure to meet production requirements. High direct yield, good and stable quality, and the effect of increasing the number of crystal nuclei produced

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

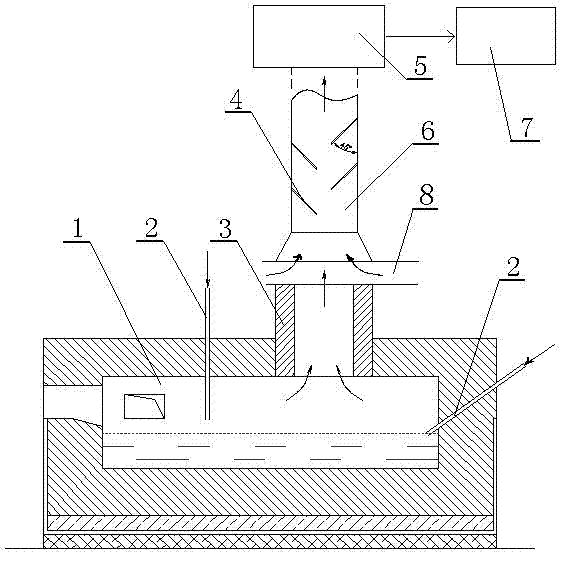

[0021] Example 1: Using No. 2 antimony ingot with a Sb content of 98.66% as raw material, the daily output of antimony trioxide products with large particle size is 18.2 tons, the average particle size is 2.5 μm and the particle size distribution is unimodal, and the main component is Sb 2 o 3 The steps of the production method of the antimony trioxide product of 99.65%, 325 mesh sieve residue less than 0.003%, and chroma L value of 98.7 are:

[0022] ①Use a diesel burner to raise the temperature of the 6m2 antimony white furnace (1) to 1000°C, then put metal antimony into the furnace to melt it into antimony liquid, and keep the temperature of the antimony liquid at 900°C;

[0023] ②Through 1 air pipe (2) installed on the top of the antimony white furnace (1) and 4 air pipes (2) installed on the furnace wall, the top blowing and side blowing are respectively blown into the antimony liquid surface to oxidize the antimony volatilize while maintaining the furnace temperature at...

Embodiment 2

[0026] Example 2: Using No. 2 antimony ingot with a Sb content of 98.66% as raw material, the daily output of antimony trioxide products with large particle size is 20.1 tons, the average particle size is 3.4 μm and the particle size distribution is a single peak, and the main component is Sb 2 o 3 The steps of the production method of the antimony trioxide product of 99.67%, 325 mesh sieve residue less than 0.003%, and chroma L value of 98.4 are:

[0027] ①Use a diesel burner to raise the temperature of the 6m2 antimony white furnace (1) to 1000°C, then put metal antimony into the furnace to melt it into antimony liquid, and keep the temperature of the antimony liquid at 950°C;

[0028] ②Through 1 air pipe (2) installed on the top of the antimony white furnace (1) and 4 air pipes (2) installed on the furnace wall, the top blowing and side blowing are respectively blown into the antimony liquid surface to oxidize the antimony volatilize while maintaining the furnace temperatu...

Embodiment 3

[0031] Example 3: Using No. 2 antimony ingot with a Sb content of 98.66% as raw material, the daily output of antimony trioxide products with large particle size is 19.7 tons, the average particle size is 4.5 μm and the particle size distribution is a single peak, and the main component is Sb 2 o 3 The steps of the production method of the antimony trioxide product with 99.61%, 325 mesh sieve residue less than 0.003%, and chromaticity L value of 98.1 are:

[0032] ①Use a diesel burner to raise the temperature of the 6m2 antimony white furnace (1) to 1000°C, then put metal antimony into the furnace to melt it into antimony liquid, and keep the temperature of the antimony liquid at 1000°C;

[0033] ②Through 1 air pipe (2) installed on the furnace top of the antimony white furnace (1) and 4 air pipes (2) installed on the furnace wall, the top blowing and side blowing are respectively blown into the antimony liquid surface to oxidize the antimony volatilize while maintaining the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com