Aftertreatment method for textile material

A technology of textile materials and fabrics, applied in the field of post-processing of textile materials, can solve the problems of resource consumption, difficulty in large-scale preparation, expensive equipment, etc., and achieve the effects of improving efficiency, reliable technical support, and increasing production quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] The discharge system includes n electrodes, n discharge needles, high-voltage wires, ground wires, DC high-voltage power supply, needle plate and electrode tray.

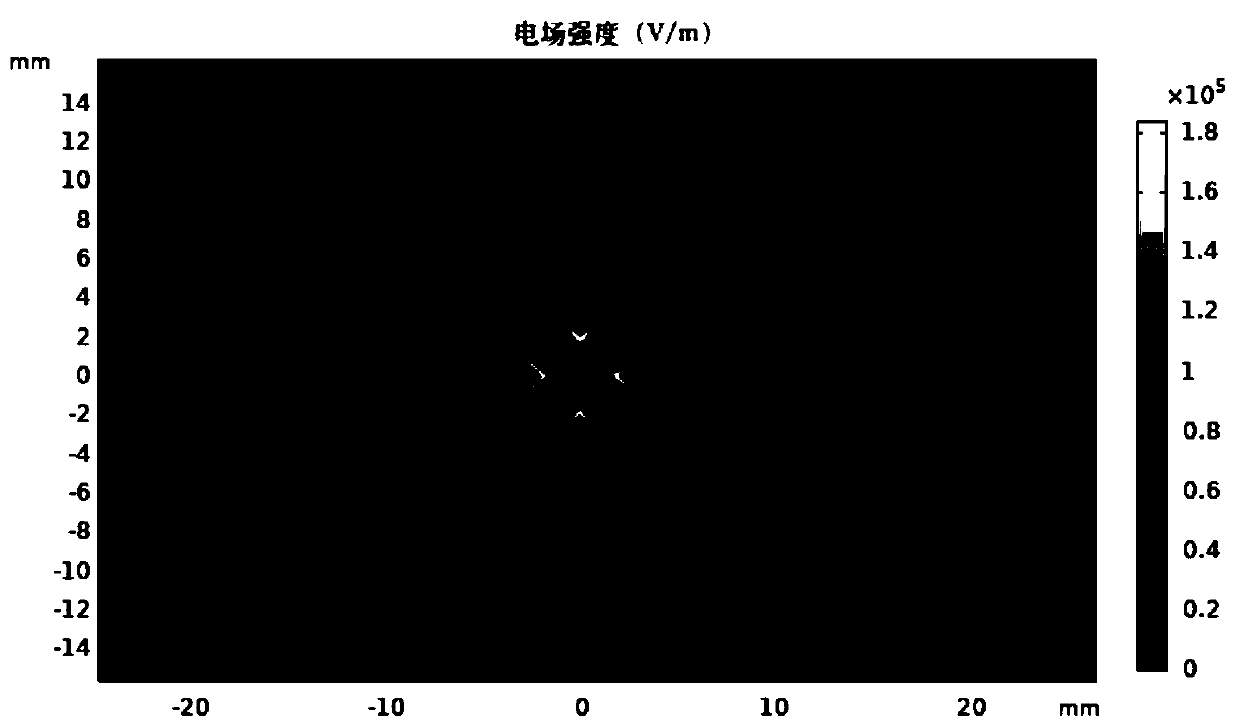

[0051] Among them, the electrode is a hollow cylindrical structure, and its three-dimensional view is as follows Figure 4 As shown; the cross-section of the hollow part 1 of the electrode is an axisymmetric quatrefoil, the quatrefoil is composed of a cross and four cones, the four cones are located at the four ends of the cross, and the cones are sharp The end is connected to the cross shape, the round thick end is far away from the cross shape, and the center of the cross shape is located on the central axis of the electrode; n-1 discharge needles are evenly distributed around the circumference of one discharge needle, and the center distance between two adjacent discharge needles is greater than 2cm; The n electrodes are located directly below the n discharge needles and correspond to them one by one, and ...

Embodiment 2

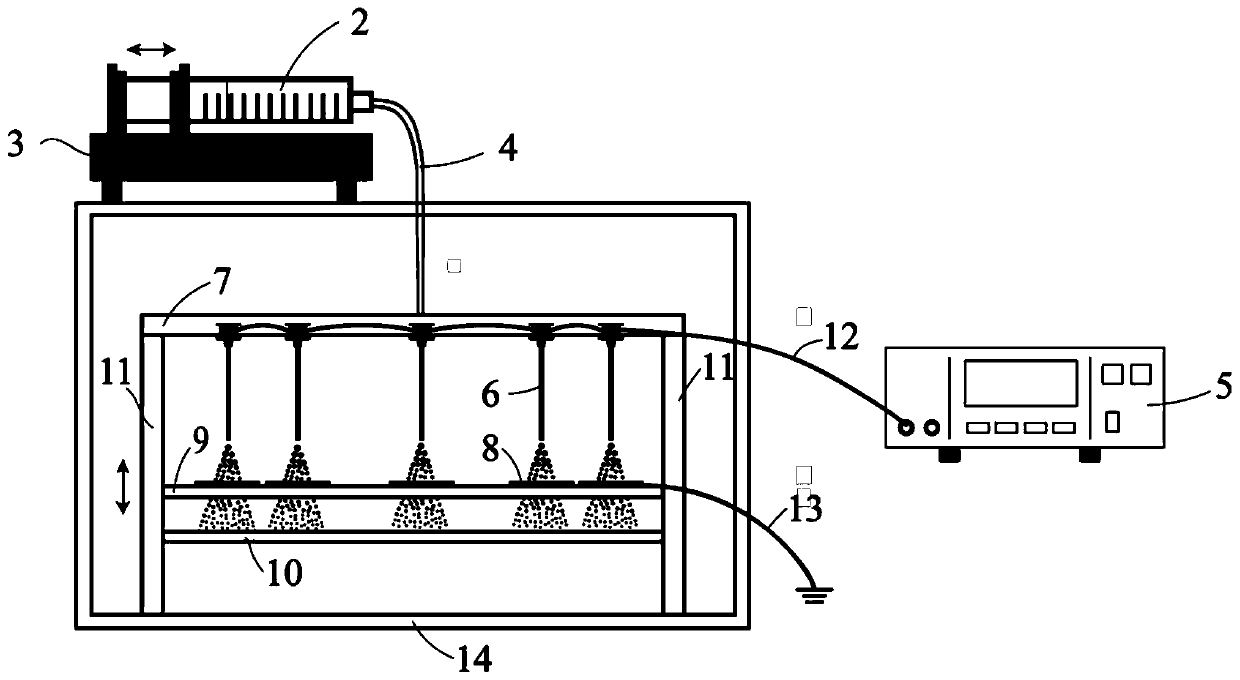

[0056] Nanostructured active water ion generators, such as image 3 As shown, including discharge system, liquid supply system and auxiliary system;

[0057] Discharging system is the discharging system in embodiment 1;

[0058] The liquid supply system consists of a syringe 2, a micro-injection pump 3 and a catheter 4, providing a stable and sufficient source of liquid to ensure that the discharge needle 6 can generate a sufficient number of nanostructured active water ions; wherein, the syringe 2 is used to accommodate the liquid , placed in the micro-injection pump 3, and communicated with n discharge needles 6 through the catheter 4, the micro-injection pump 3 provides a stable linear thrust to ensure that the discharge needle 6 connected to the syringe 2 can maintain a stable Taylor cone liquid;

[0059] The auxiliary system is composed of a stage 10, two lifting rods 11 and a box cover 14; among them, the object stage 10 is located under the electrode tray 9, and the di...

Embodiment 3

[0062] The anti-fluffing and pilling modification method of wool fabric is to lay the wool fabric on the stage of the nanostructure active water ion generating device of embodiment 2, and add 10mL of high-purity water with a resistivity of 18MΩ cm into the syringe at the same time, Start the liquid supply system and the discharge system, keep it for a period of time, and obtain the anti-pilling modified wool fabric, wherein the distance between the discharge needle and the electrode ranges from 0.5 to 2 cm, and the range of the DC voltage of the DC high-voltage power supply -3.8~-7kV, the value range of the infusion rate of the micro injection pump is 0.9~10μL / min, and the value range of the distance between the electrode tray and the stage is 0~10cm.

[0063] The specific processing steps are as follows:

[0064] (1) Cut 100% merino wool weft-knitted plain knitted fabric (the average fiber diameter is 19.5 μm, and the yarn count is 2 / 30Nm) into 15 square samples of 4cm×4cm si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com