Patents

Literature

30results about How to "Accelerate the speed of maturation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cultivation method of ginkgo trees

InactiveCN105309157AAccelerate the speed of maturationImprove survival rateHorticultureSeedlingSprigging

The invention provides a cultivation method of ginkgo trees, belongs to the field of agriculture, particularly relates to the cultivation method of the ginkgo trees and provides a scientific and reasonable planting method of the ginkgo trees. The cultivation method of the ginkgo trees comprises steps as follows: (1), selection of land for seedling raising: a flat and leeward place which has deep soil layers, loose and fertile soil and good water drainage property, is exposed to the sun and can be conveniently watered and well-drained is selected for seedling raising; (2), germination acceleration and sowing: sowing can be performed immediately after sowing in autumn, and germination acceleration is unnecessary; (3), seedling management: seedlings have a short growth period and stop growing soon, root systems are not strong, and fertilizer application and dressing can promote growth of the seedlings remarkably; (4), cutting of the seedlings: the land with loose soil and good water drainage property is selected, and base fertilizers are sufficiently applied; (5), scion treatment: branches growing for 1-3 years are selected from a superior ginkgo tree growing strongly and cut into cuttings with the length of 10-15 cm, and the lower ends of the cuttings are treated with rooting powder and soaked for 10 seconds.

Owner:庄芳

Seed germination and rapid propagation method for cymbidium orchid

InactiveCN106258960AAccelerate the speed of maturationFast growthHorticulture methodsPlant tissue cultureOrchisSpore germination

The invention discloses a seed germination and rapid propagation method for cymbidium orchid, and relates to the technical field of plant tissue culture. The method comprises the steps that culturing is conducted through a seed germination culture medium and then conducted through a protocorm seedling differentiation culture medium, wherein the seed germination culture medium is a VW culture medium containing 6-benzyl adenine with the concentration of 0.5 mg / L to 1.0 mg / L, and the protocorm seedling differentiation culture medium is a KC culture medium containing banana juice with the mass fraction of 10%. According to the method, the seed germination and propagation speed of the cymbidium orchid can be significantly increased, the method is especially suitable for Zijingxiangyun cymbidium orchid and Laoranzi varieties difficult to germinate and culture, the culture time can be shortened, the culture technology is simple, conditions are created for commercialized production of the cymbidium orchid, and the orchid market demand exceeding supply is met.

Owner:SHANDONG CROP GERMPLASM CENT

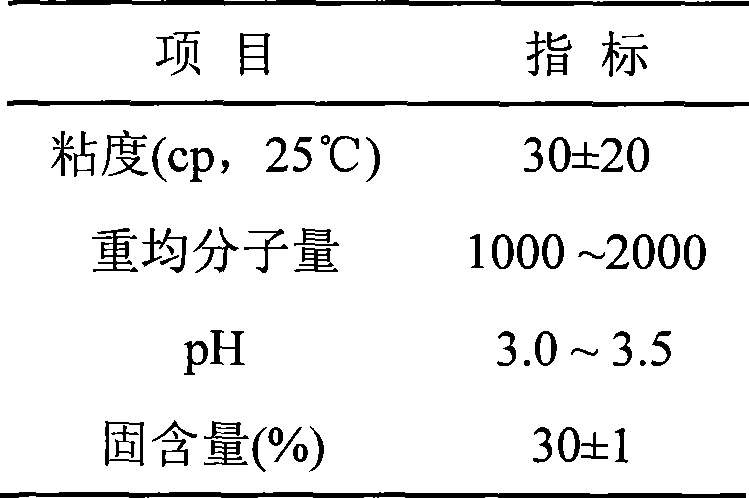

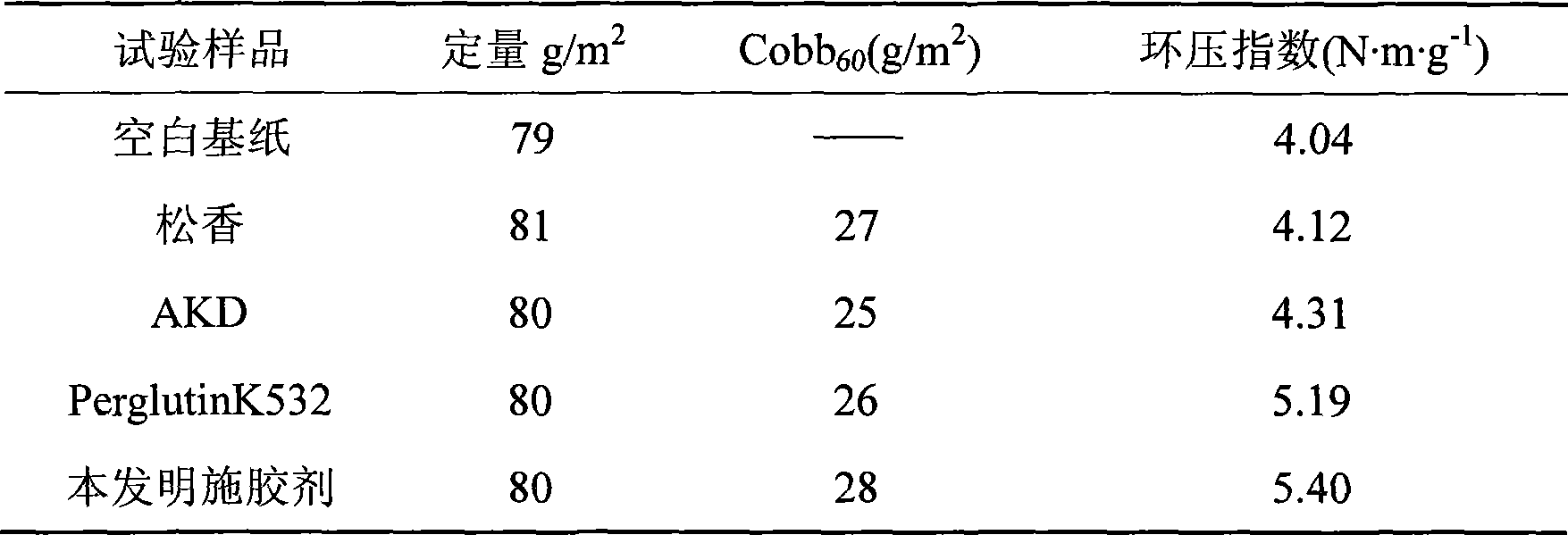

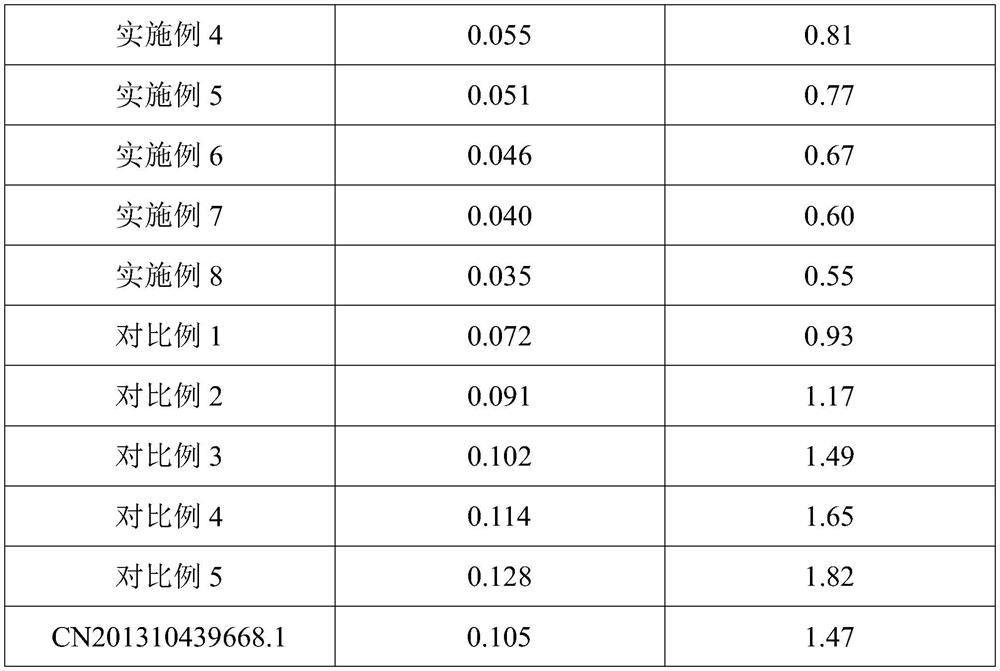

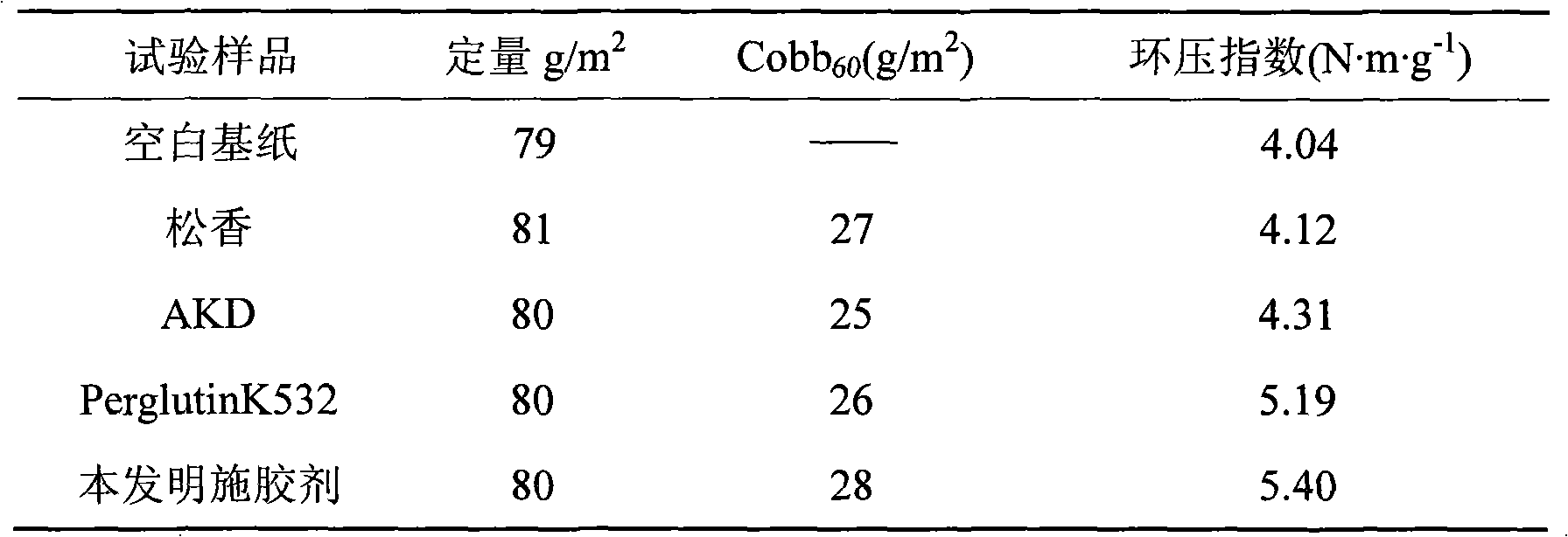

Synthetic method for cationic surface sizing agent

ActiveCN101519859AImprove conversion rateMild responseWater-repelling agents additionOrganic solventEmulsion polymerization

The invention provides a synthetic method for a cationic surface sizing agent, which comprises the following steps: taking an organic solvent as a homogeneous reaction medium, taking styrene, acrylic ester and cationic monomer as comonomers, and adding a chain transfer agent and an initiator for polyreaction to prepare the cationic surface sizing agent with weight average molar mass between 1,000 and 2,000; and the weight percentage of the components is as follows: 60 to 75 percent of the organic solvent, 10 to 15 percent of the styrene, 10 to 15 percent of the acrylic ester, 2 to 10 percent of the cationic monomer, 0.1 to 1 percent of the chain transfer agent and 0.1 to 1 percent of the initiator. The synthetic method adopts a homogeneous non-emulsion polymerization process and a high-efficiency catalytic system, and has high conversion rate; and the prepared surface sizing agent can improve the ring crush strength of paper, improve a Cobb value, quicken mature speed without getting damp, reduce linting and dusting of the paper, obviously improve water resistance and strength of the paper, and improve application performances such as wear resistance, hydrophilicity of printing ink, ventilation property, stiffness and the like.

Owner:广州星业科技股份有限公司

Potato planting method applicable to barren area

InactiveCN107926565AIncrease plant robustnessIncrease growth rateFertilising methodsRoot crop cultivationShootCuticle

The invention provides a potato planting method suitable for barren areas with fast growth, high yield and strong plants. A method for planting potatoes suitable for barren areas comprises the following steps. (1) Select seed potatoes with fresh skin color, no cracks, no disease spots, and the size of the potato pieces is about 30-50 grams. (2) Treatment of seed potatoes; tubers. When cutting, it should be cut longitudinally from the top to the navel. (3) Germination; before germination and sowing, put the seed potatoes in a room at 15-20°C and cover them with 2 cm thick moist sandy soil; when the buds grow to 0.5-1 cm, put them in a greenhouse for budding. (4) Choose fertilizer according to the growth period. Applying enough base fertilizer can promote the luxuriant branches and leaves of potatoes in the early stage and the root system to develop. (5) Field management, early topdressing seedling fertilizer, see seedling topdressing budding fertilizer and long potato fertilizer.

Owner:彭钦龙

Preparation method of broad bean paste

ActiveCN107981219AExtended shelf lifeFirmly lock in nutrientsFood ingredient as antioxidantFood preservationMicroorganismAdditive ingredient

The invention provides a preparation method of broad bean paste. The preparation method comprises the following steps: (A) preparing broad bean halves from dried bean halves; (B) boiling with ChineseToona bark, tupelo bark, funnel and water to obtain soup to cover the broad bean halves; (C) covering, in layers, with golden leaves, folium cinnamomi longepaniculati, bay leaves and pumpkin leaves, and performing primary fermentation; (D) removing mould and impurities; (E) adding salt and soy sauce and performing secondary fermentation; (F) adding chilies, rhizoma kaempferiae and ingredients forthird fermentation, and performing third fermentation; (G) preparing pickling main ingredients; (H) uniformly mixing the bean halves after the three fermentation, the pickling main ingredients, soy sauce, garlic and the like; (I) preparing chili oil and uniformly mixing the chili oil with the mixture obtained in the step (H) to obtain the broad bean paste. According to the preparation method provided by the invention, peculiar smell generated by repeated natural fermentation can be effectively controlled, water loss is reduced, sufficient reaction of microorganisms is promoted, and the producthas bright color and rich sauce aroma.

Owner:平昌县文家何大妈食品有限公司

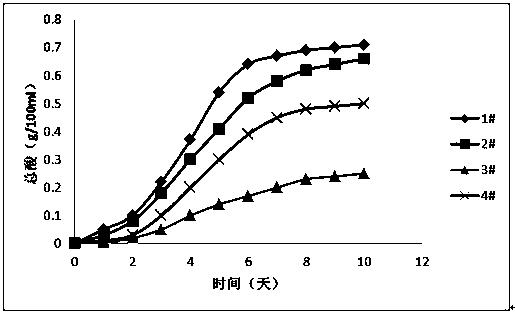

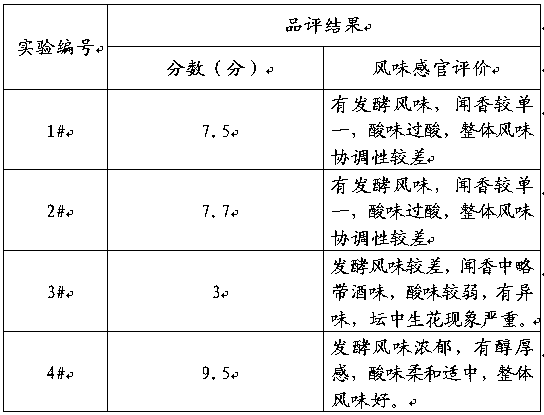

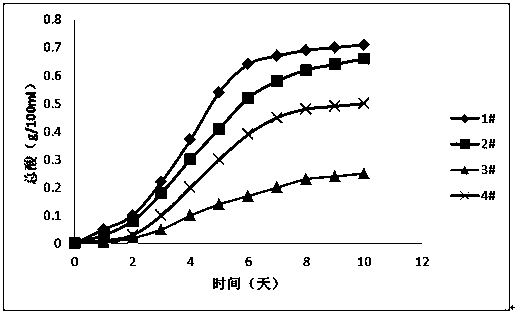

A kind of method for fermenting flavored pickled vegetables

ActiveCN104543896BGrowth inhibitionFermentation is fast, safe and high qualityClimate change adaptationFood scienceYeastSalt water

The invention belongs to the field of food processing, and in particular discloses a method for fermenting flavor pickled green vegetables. The method comprises the following steps: 1) washing and removing sand from fresh green vegetables, and draining off the water for later use; 2) putting 100 parts of the fresh green vegetables obtained in the step 1) into a pickling jar, adding 100 parts of salt water with 1-20% by mass of salt, and keeping the contents of the green vegetables and the salt of the water in the pickling jar being both 1-10%; 3) adding 0.1-1 part of lactobacillus plantarum and 0.1-0.5 part of yeast into the pickling jar of the step 2), adding jar opening sealing water for sealing to ferment for 1-10 days at normal temperature, and taking out the flavor pickled green vegetables to eat directly. As lactobacillus plantarum and yeast are used in match in the green vegetable fermentation process, lactic acid in the flavor pickled green vegetables can be rapidly produced and accumulated because of the lactobacillus plantarum, the aging speed of the flavor pickled green vegetables is increased, and the fermentation time is shortened; due to addition of the ester-producing yeast, the flavor pickled green vegetables can be enriched in fragrance and fermented, and ester substances in the flavor pickled green vegetables can be rapidly generated.

Owner:UNI PRESIDENT ENTERPRISES CHINA INVESTMENT CO LTD KUNSHAN RES & DEV CENT +1

Method for cultivating black fungus

InactiveCN109496679AImprove survival rateIncrease growth rateCultivating equipmentsMushroom cultivationAgaricObserved Survival

The invention discloses a method for cultivating black fungus. The method comprises the following steps: (1) seed production; (2) black fungus wood preparation; (3) inoculation; (4) transplanting management; (5) bulk pile arrangement on a yard; and (6) fruiting management. The method has the advantages of high yield, easiness in management, low planting cost, increase of the survival rate of the black fungus by a scientific black fungus planting process, increase of the growth rate and the ripening rate of the black fungus, and convenience in promotion of the black fungus.

Owner:宁远盛景农业发展有限公司

Tomato facility organic cultivation soilless culture solution and use method

InactiveCN109206200AFull of ruddyColor cost favoriteMagnesium fertilisersExcrement fertilisersBiotechnologyInorganic salts

The invention relates to a tomato facility organic cultivation soilless culture solution, which comprises: 100-200l of biogas slurry, 5-10g of sodium selenite, inorganic salt component and water. Thefermentation preparation process of the biogas slurry includes: adding a mixture of rice bran, fern root, perlite, straw, sludge, animal dung, corn flour and peanut shell chips into a biogas slurry fermentation pool for fermentation for 50-80 days. The tomato facility organic cultivation soilless culture solution provided by the invention is added with sodium selenite, can add organic selenium element to the cultivated tomatoes to acquire selenium-rich tomatoes, which have fuller ruddiness than the original ones without adding of sodium selenite, the color and cost are pleasing, the added value of tomatoes is increased, the yield of the obtained selenium-rich tomatoes is 20-25% higher than that of other cultivation methods, and the selenium content is as high as 0.06-0.15mg / kg.

Owner:天津市君利种植专业合作社

Planting method of ginger

InactiveCN107593350AImprove survival rateIncrease growth rateFertilising methodsRoot crop cultivationObserved SurvivalMoisture

The invention relates to a planting method of ginger. The planting method includes following steps: S1, planting; S2, shading: shading ginger; S3, intertilling for weeding: intertilling for weeding from seedling emergence to shoot bud collection, and maintaining soil loose and free of weed; S4, watering reasonably: according to weather and soil moisture, appropriately watering, and watering once aweek to maintain soil wet as water demand is high in the vigorous growing period; watering for a time after ginger harvesting is finished; S5, fertilizing scientifically; S5, harvesting ginger: harvesting and breaking off by hands, and digging out seed roots for tillering and replanting after the ginger is harvested continuously for three years. The planting method has the advantages that survival rate, growing speed and maturing speed of the ginger are increased, yield of the ginger is increased, and yield increase and income increase of growers are realized.

Owner:GUILIN WEIMEIYUAN RESTAURANT MANAGEMENT

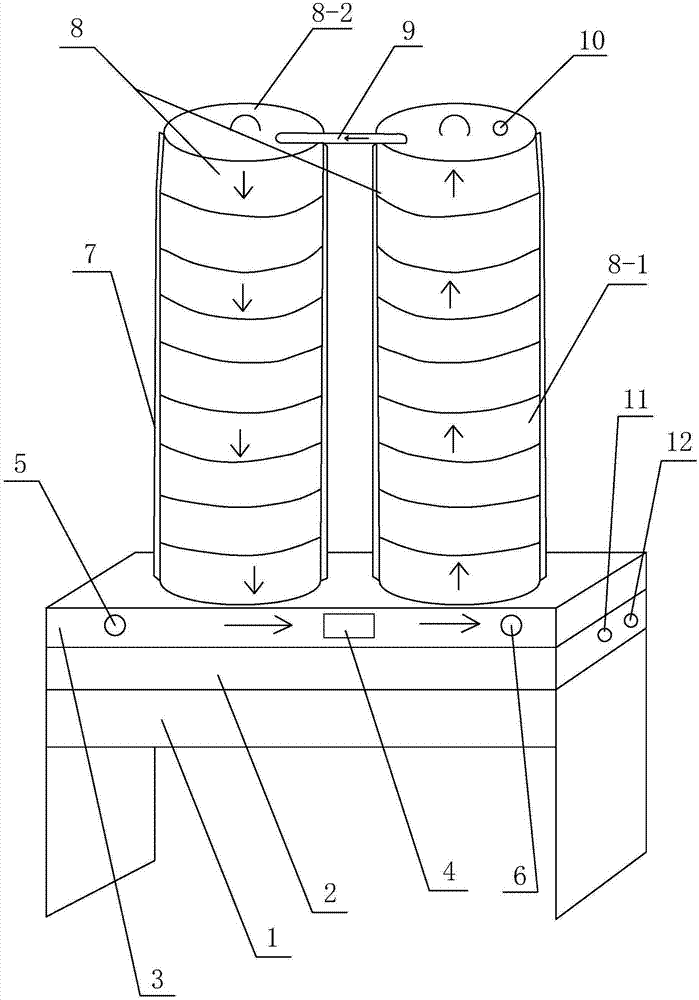

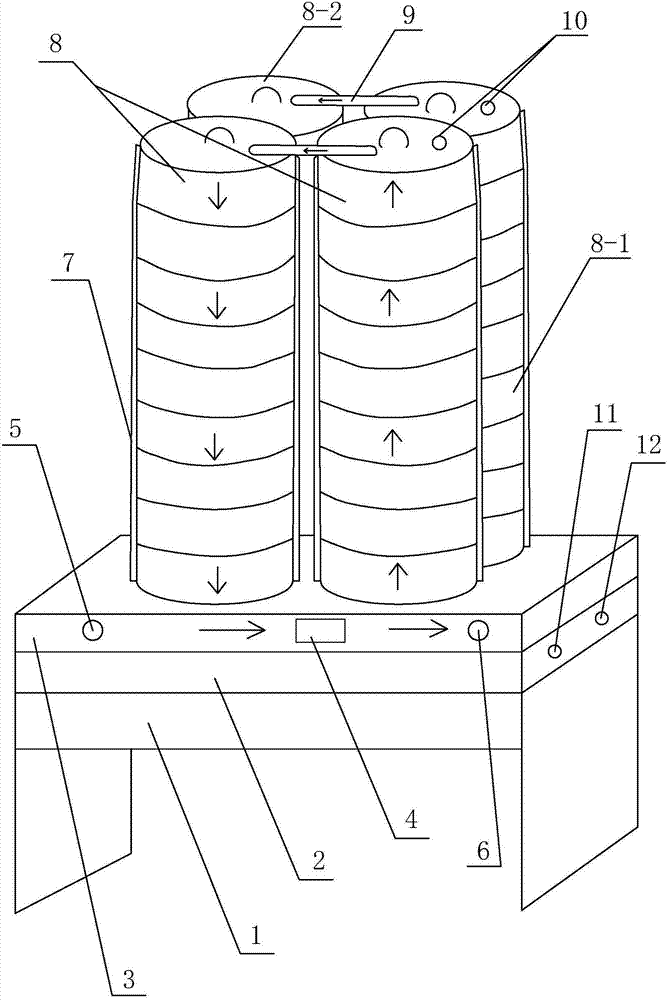

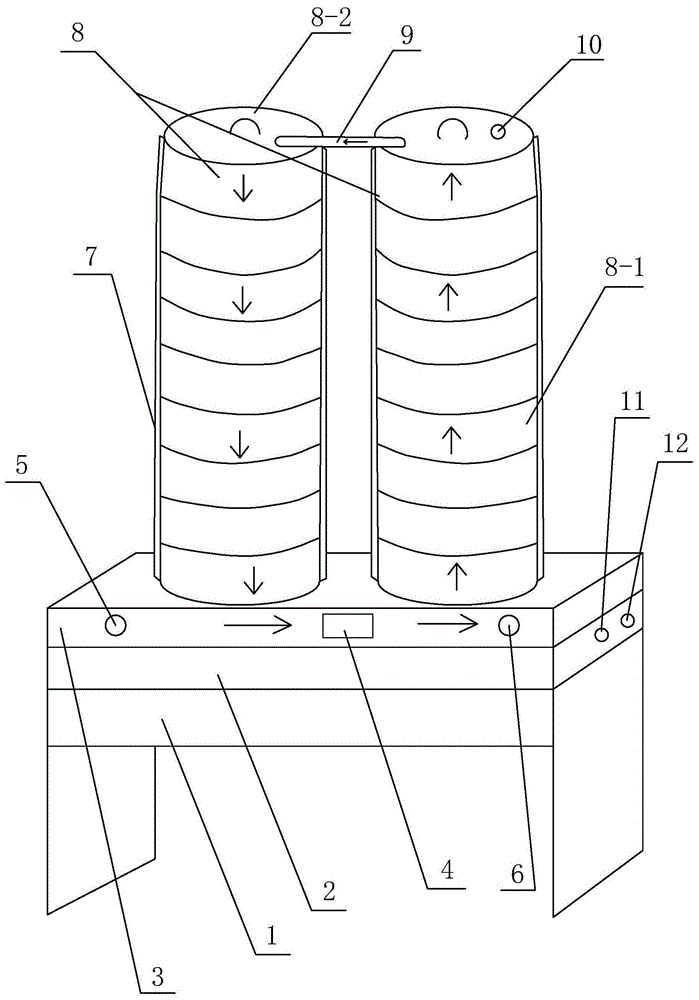

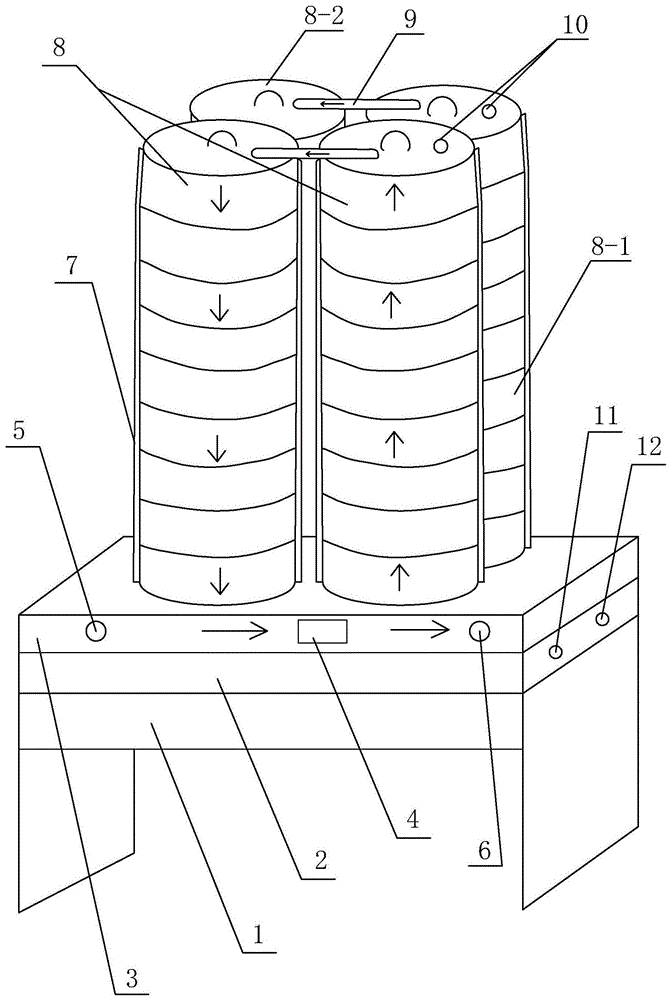

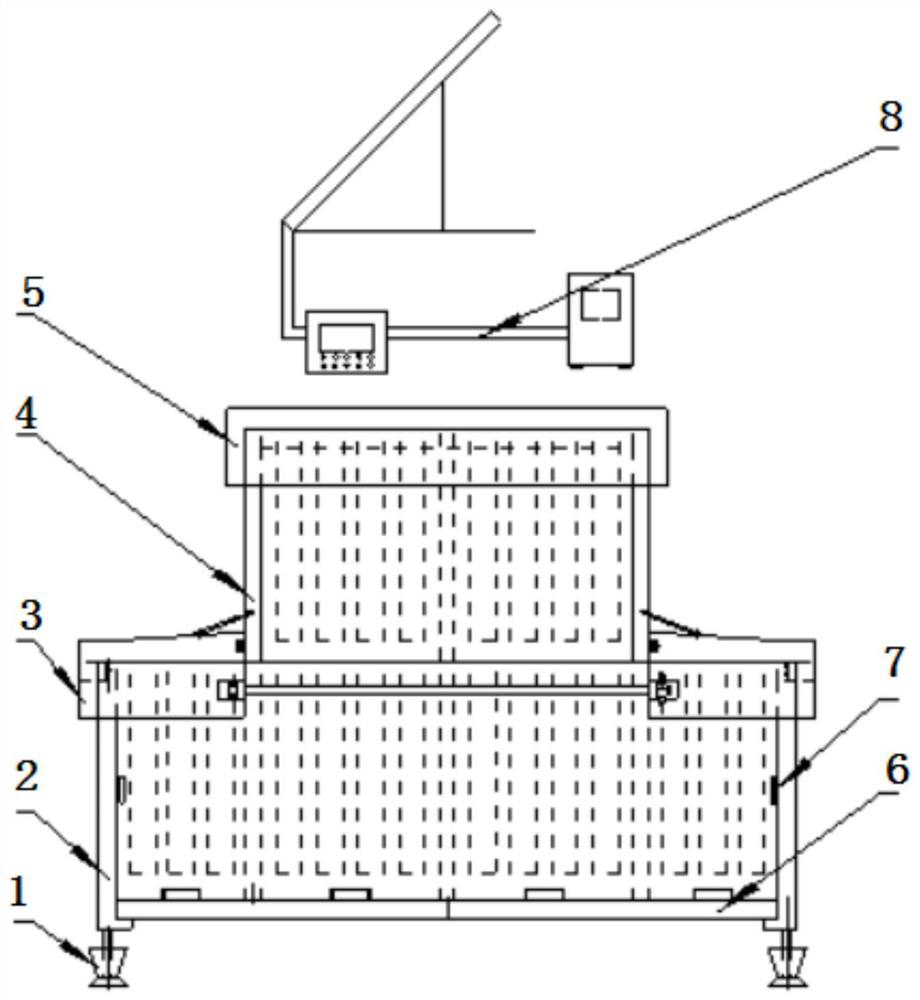

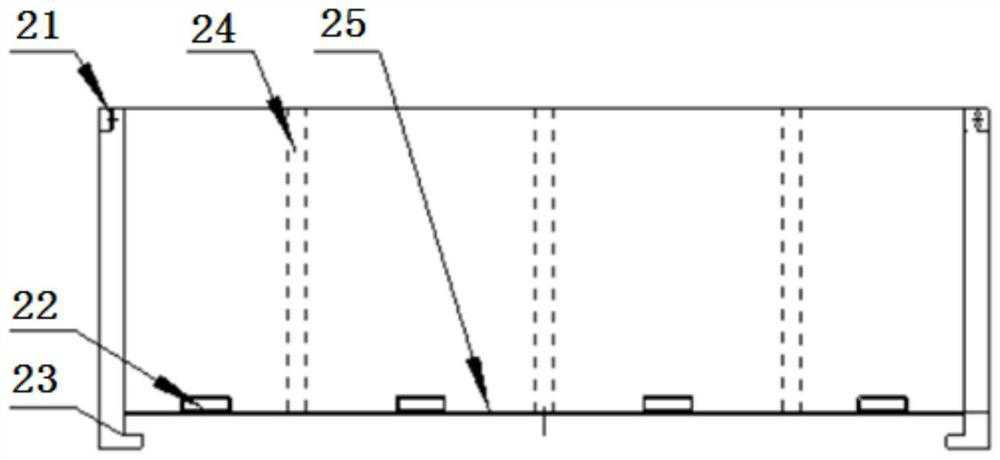

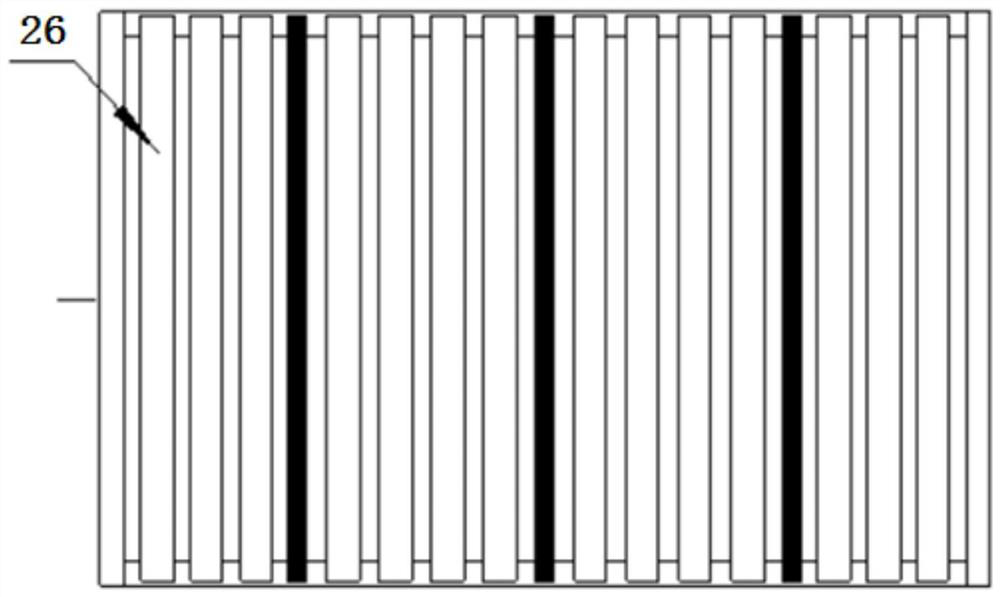

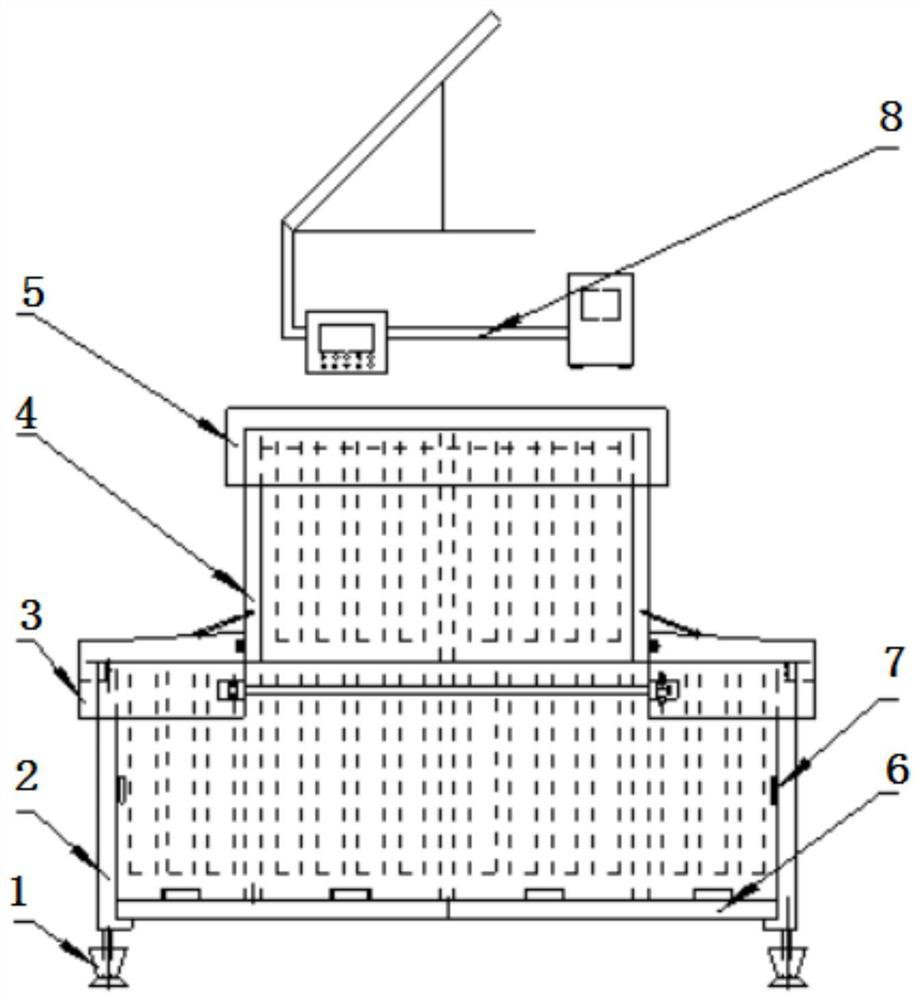

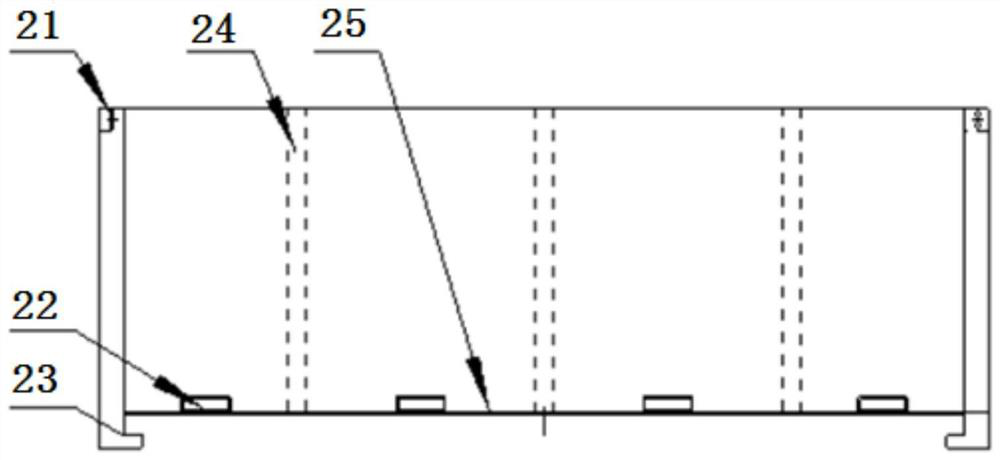

Circulation type energy-saving and water-saving food steamer

ActiveCN104490256AEvenly heatedAccelerate the speed of maturationSteam cooking vesselsEngineeringControl switch

The invention discloses a circulation type energy-saving and water-saving food steamer. The circulation type energy-saving and water-saving food steamer comprises a steam furnace, a food steamer base and an air pump arranged in the food steamer base; the food steamer base is installed on the steam furnace; the circulation type energy-saving and water-saving food steamer further comprises a steam storage tank and at least one set of food steamer bodies; the steam storage tank is arranged between the steam furnace and the food steamer base; each set of food steamer bodies comprises two food steamer bodies; the food steamer bodies are installed on the food steamer base; each food steamer body is mainly composed of a plurality of layers of stacked food steamer drawers and a food steamer cover arranged on the food steamer drawer on the top layer in a covering mode, and an air tube is connected between two food steamer covers of each set of food steamer bodies. An air inlet of the air pump is connected with the bottom of one food steamer body of each set of food steamer bodies, and an air outlet of the air pump is connected with the bottom of the other one of each set of food steamer bodies; and a pressure limiting valve is arranged on the food steamer covers of each set of food steamer bodies, and a control switch is further arranged on the steam storage tank. The circulation type energy-saving and water-saving food steamer has the beneficial effects of being simple in structure and high in steaming time and saving energy and water; the steaming capacity can be improved; and the circulation type energy-saving and water-saving food steamer can be used for heat preservation fermentation.

Owner:曹传喜

A kind of Cymbidium seed germination rapid propagation method

InactiveCN106258960BAccelerate the speed of maturationFast growthPlant tissue cultureHorticulture methodsOrchisCulture mediums

The invention discloses a seed germination and rapid propagation method for cymbidium orchid, and relates to the technical field of plant tissue culture. The method comprises the steps that culturing is conducted through a seed germination culture medium and then conducted through a protocorm seedling differentiation culture medium, wherein the seed germination culture medium is a VW culture medium containing 6-benzyl adenine with the concentration of 0.5 mg / L to 1.0 mg / L, and the protocorm seedling differentiation culture medium is a KC culture medium containing banana juice with the mass fraction of 10%. According to the method, the seed germination and propagation speed of the cymbidium orchid can be significantly increased, the method is especially suitable for Zijingxiangyun cymbidium orchid and Laoranzi varieties difficult to germinate and culture, the culture time can be shortened, the culture technology is simple, conditions are created for commercialized production of the cymbidium orchid, and the orchid market demand exceeding supply is met.

Owner:SHANDONG CROP GERMPLASM CENT

Low-salt semi-dry fermentation method for pickled vegetables

InactiveCN113017045AReduce moistureReduce salt contentClimate change adaptationFood scienceBiotechnologyLactic acid bacterium

The invention belongs to the field of food, and particularly relates to a low-salt semi-dry state fermentation method for pickled vegetables. The method provided by the invention comprises the following steps: preparing low-salt lactic acid bacteria liquid saline water, soaking fresh vegetables, performing low-temperature vacuum dehydration, and performing sealed anaerobic fermentation. The preparation method comprises the following steps: firstly preparing low-salt lactic acid bacteria liquid salt water, then putting fresh vegetables into the low-salt lactic acid bacteria liquid salt water for dipping, then fishing out the dipped vegetables, performing vacuum dehydration under a low-temperature condition, finally putting the dehydrated vegetables into a closed container, pressing, and performing anaerobic fermentation until the vegetables are mature to obtain the low-salt semi-dry state fermented pickled vegetables. The pickled vegetables prepared by the method disclosed by the invention are low in salt content, rich in flavor substance components and stable in quality, zero discharge of salting wastewater and cleaning wastewater is realized, and the pickled vegetables are clean and environment-friendly.

Owner:付桂英

Circulating energy-saving water-saving steamer

ActiveCN104490256BEvenly heatedAccelerate the speed of maturationSteam cooking vesselsWater savingEngineering

The invention discloses a circulation type energy-saving and water-saving food steamer. The circulation type energy-saving and water-saving food steamer comprises a steam furnace, a food steamer base and an air pump arranged in the food steamer base; the food steamer base is installed on the steam furnace; the circulation type energy-saving and water-saving food steamer further comprises a steam storage tank and at least one set of food steamer bodies; the steam storage tank is arranged between the steam furnace and the food steamer base; each set of food steamer bodies comprises two food steamer bodies; the food steamer bodies are installed on the food steamer base; each food steamer body is mainly composed of a plurality of layers of stacked food steamer drawers and a food steamer cover arranged on the food steamer drawer on the top layer in a covering mode, and an air tube is connected between two food steamer covers of each set of food steamer bodies. An air inlet of the air pump is connected with the bottom of one food steamer body of each set of food steamer bodies, and an air outlet of the air pump is connected with the bottom of the other one of each set of food steamer bodies; and a pressure limiting valve is arranged on the food steamer covers of each set of food steamer bodies, and a control switch is further arranged on the steam storage tank. The circulation type energy-saving and water-saving food steamer has the beneficial effects of being simple in structure and high in steaming time and saving energy and water; the steaming capacity can be improved; and the circulation type energy-saving and water-saving food steamer can be used for heat preservation fermentation.

Owner:曹传喜

Selenium-enriched potato planting method suitable for barren areas

InactiveCN107853113AIncrease plant robustnessIncrease growth rateFertilising methodsRoot crop cultivationCuticleShoot

The invention provides a selenium-enriched potato planting method suitable for barren areas with fast growth rate, high yield and strong plants. A method for planting selenium-enriched potatoes suitable for barren areas, comprising the following steps: 1) selecting seed potatoes with fresh skin color, no cracks, no disease spots, and the size of the potato pieces being preferably about 30-50 grams. 2) Treatment of seed potatoes; tubers. When cutting, it should be cut longitudinally from the top to the navel. 3) Germination; before germination and sowing, put the seed potatoes in a room at 15-20°C and cover with 2 cm thick moist sandy loam; when the buds grow to 0.5-1 cm, put them in a greenhouse for budding. 4) Choose fertilizer according to the growth period. Applying sufficient base fertilizer can promote the luxuriant branches and leaves of potatoes in the early stage and the root system to develop. 5) Field management, topdressing seedling fertilizer early, watching seedling topdressing budding fertilizer and long potato fertilizer.

Owner:吴绍玲

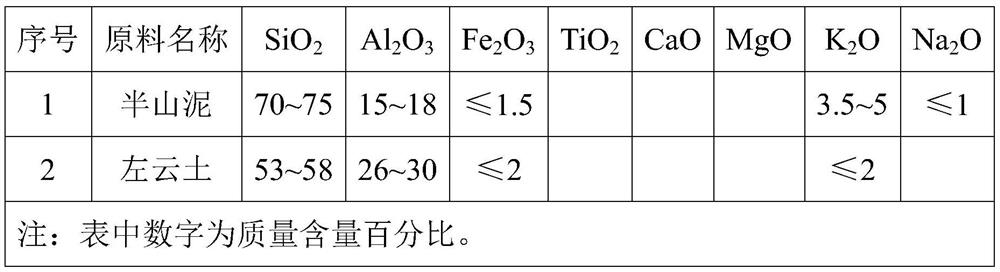

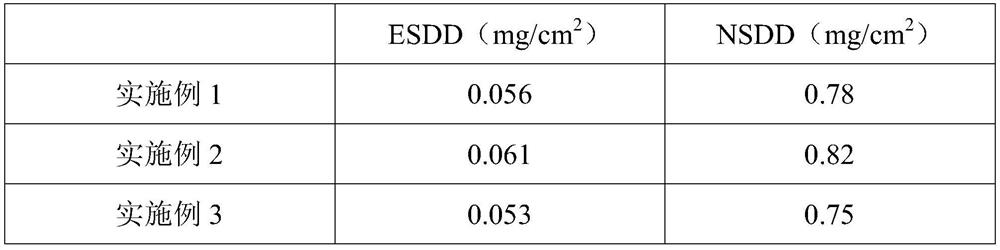

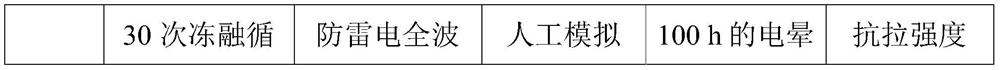

A kind of glaze for ultra-high voltage porcelain insulator and its making method

The invention provides a formula and a preparation method of a glaze for UHV porcelain insulators. The formula includes the following raw materials in parts by weight: 20-33 parts of quartz, 10-18 parts of illite, 10-15 parts of mountain clay, silicon 10-15 parts of zirconium acid powder, 4-7 parts of white corundum powder, 1-5 parts of nano-silica, 3-6 parts of wollastonite, 1-2 parts of barium carbonate, 7-12 parts of levodolite, manganese oxide 5-7 parts, 1-2 parts of iron oxide, 1-2 parts of chromium oxide, 3-5 parts of antimony oxide, 2-8 parts of sepiolite powder, 2-8 parts of bentonite. The preparation method comprises the steps of preparing nano silicon dioxide composite modified sepiolite powder, preparing solid solution, wet ball milling and adjusting the specific gravity of glaze slurry. The glaze obtained by the formula and method of the invention makes the insulator have very excellent pollution resistance and voltage equalization performance, and the mechanical performance and electrical performance are also greatly improved, which is suitable for the UHV direct current transmission system.

Owner:江西高强电瓷集团有限公司

Synthetic method for cationic surface sizing agent

ActiveCN101519859BImprove conversion rateMild responseWater-repelling agents additionPrinting inkSizing

Owner:广州星业科技股份有限公司

Special foliar fertilizer for citrus reiculata blanco and preparation method thereof

InactiveCN108997053APromote growthHigh in nutrientsMagnesium fertilisersAlkali orthophosphate fertiliserRare-earth elementPhosphate

The invention provides a special foliar fertilizer for citrus reiculata blanco and a preparation method thereof, and belongs to the technical field of foliar fertilizers for the citrus reiculata blanco. The foliar fertilizer is prepared by mixing the following raw materials in parts by weight: 40-50 parts of urea, 5-7 parts of potassium dihydrogen phosphate, 1.0-1.2 parts of calcium nitrate, 3-5 parts of rare earth elements, 2-3 parts of 6-benzylaminopurine, 6-8 parts of amino acid, 2-3 parts of EDTA-Mg, 1-2 parts of EDTA-Fe, 3-4 parts of zinc sulfate and 2-3 parts of a microbial inoculum. Theinvention further provides the preparation method of the foliar fertilizer. The preparation method is simple, and is suitable for large-scale application; the obtained foliar fertilizer is rich in avariety of mineral trace elements and other beneficial components and can meet growth and development needs of citrus reiculata blanco fruits.

Owner:博白县百家水果专业合作社

Iron-enriched potato planting method applicable to barren area

InactiveCN107926562AIncrease plant robustnessIncrease growth rateFertilising methodsRoot crop cultivationFertilizerGram

The invention provides an iron-rich potato planting method suitable for barren areas with fast growth, high yield and strong plants. A method for planting iron-rich potatoes suitable for barren areas, comprising the following steps. (1) Select seed potatoes, choose fresh skin color, no cracks, no disease spots, and the size of the potato pieces is about 30-40 grams. (2) Treatment of seed potatoes; tubers. When cutting, it should be cut longitudinally from the top to the navel. (3) Germination; before germination and sowing, put the seed potatoes in a room at 15-20°C and cover with 2 cm thick moist clay; when the buds grow to 1-1.5 cm, put them in a greenhouse for budding. (4) Choose fertilizer according to the growth period. Applying enough base fertilizer can promote the luxuriant branches and leaves of potatoes in the early stage and the root system to develop. (5) Field management, early topdressing seedling fertilizer, see seedling topdressing budding fertilizer and long potato fertilizer.

Owner:吴绍玲

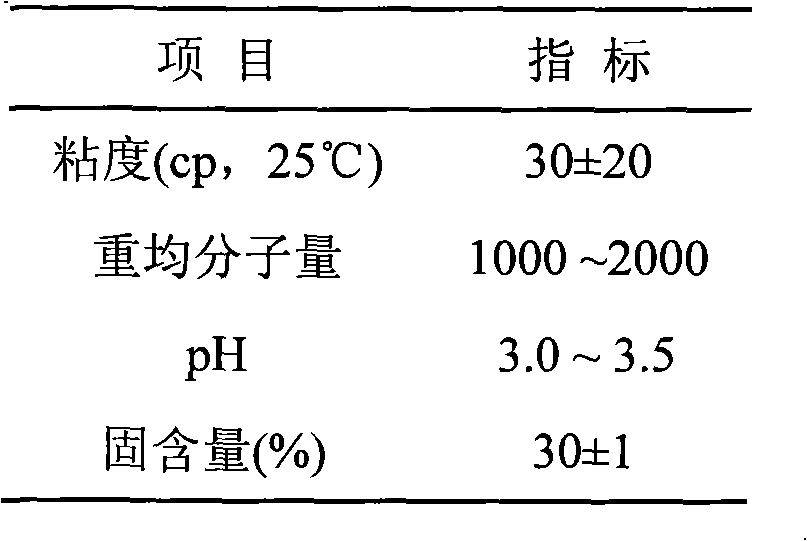

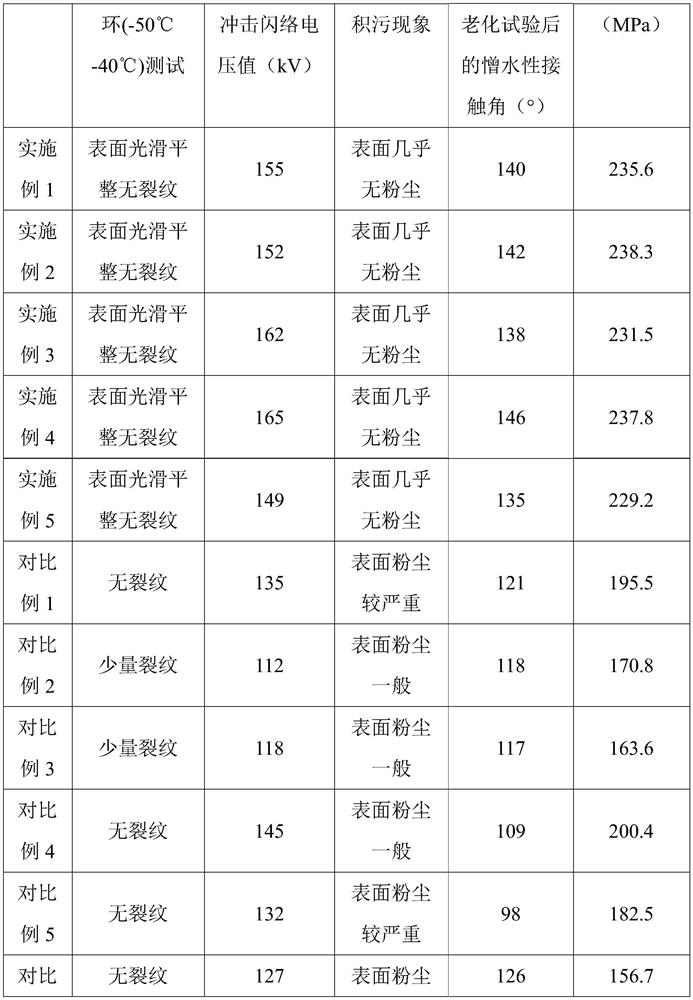

A high-strength anti-aging porcelain insulator and its preparation method

ActiveCN110845224BHigh hardnessImprove compactnessCeramic materials productionClaywaresFiberBoron nitride

The invention provides a high-strength anti-aging porcelain insulator, which comprises the following raw materials in parts by weight: 20-32 parts of illite, 22-30 parts of quartz, 15-25 parts of molecular sieve, 10-18 parts of aluminum oxide, 10-18 parts of zirconium, 10-20 parts of reinforcing fiber, 1-8 parts of nano-titanium dioxide, 1-8 parts of nano-silicon dioxide, 1-8 parts of nano-silicon nitride, 1-8 parts of nano-boron nitride, sepiolite powder 2 to 8 parts, 2 to 8 parts of bentonite. The insulator of the invention adopts multiple functional raw materials to compound, so as to improve the aging resistance and mechanical strength of the insulator. The present invention also provides a preparation method of a high-strength anti-aging porcelain insulator, comprising the following steps: preparation of nano-silica composite modified alumina-sepiolite powder; mixing and ball milling; sieving and iron removal; Filtration and aging; blank forming and drying; glazing and firing; cutting and polishing, glue binding and curing. The insulator obtained by the method of the invention has the advantages of high mechanical strength, pollution resistance, flashover resistance and aging resistance.

Owner:江西高鑫电瓷电器有限公司

Beehive for producing ripe honey and method for producing ripe honey

The embodiment of the present invention relates to the technical field of bee breeding, and provides a beehive for producing mature honey. The beehive for producing mature honey provided by the embodiment of the present invention includes a first box body, a second box body and a vertical king partition, wherein the beehive has a configuration in a state of flowing honey, and in the configuration of a flowing honey state, the vertical The king partition is detachably arranged inside the first box, and divides the first box into a breeding area and a honey storage area, and at least one second box is detachably superimposed on the top surface of the first box , and the inside of at least one second box communicates with the honey storage area and is isolated from the breeding area through a vertical king partition. In the beehive for producing mature honey provided by the embodiment of the present invention, the vertical king partition is arranged in the first box, so that the bees can be in the honey storage area of the first box and at least one second box that is superimposed Production, honey brewing and honey storage have improved the efficiency of collecting and brewing honey, accelerated the speed of honey maturation, and increased the output of mature honey.

Owner:BEE RES INST CHINESE ACAD OF AGRI SCI

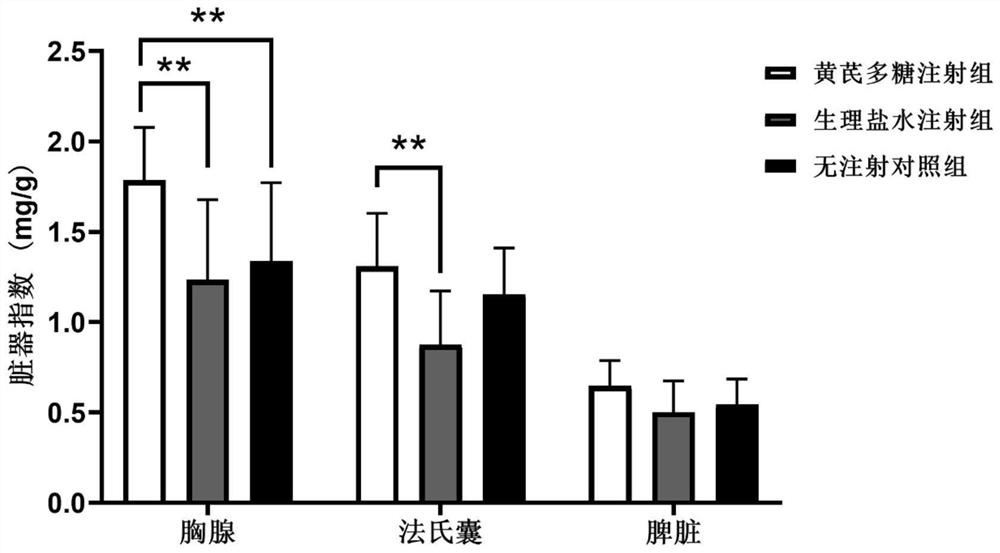

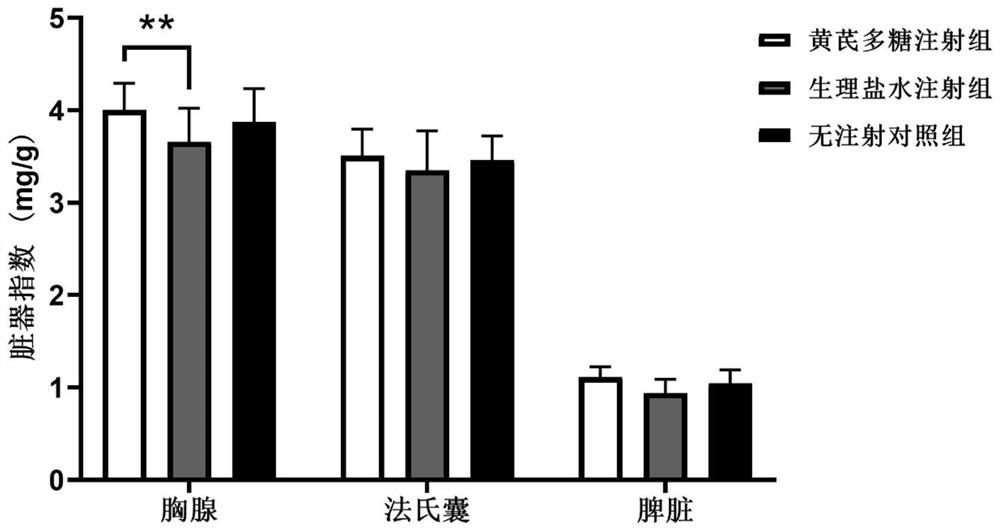

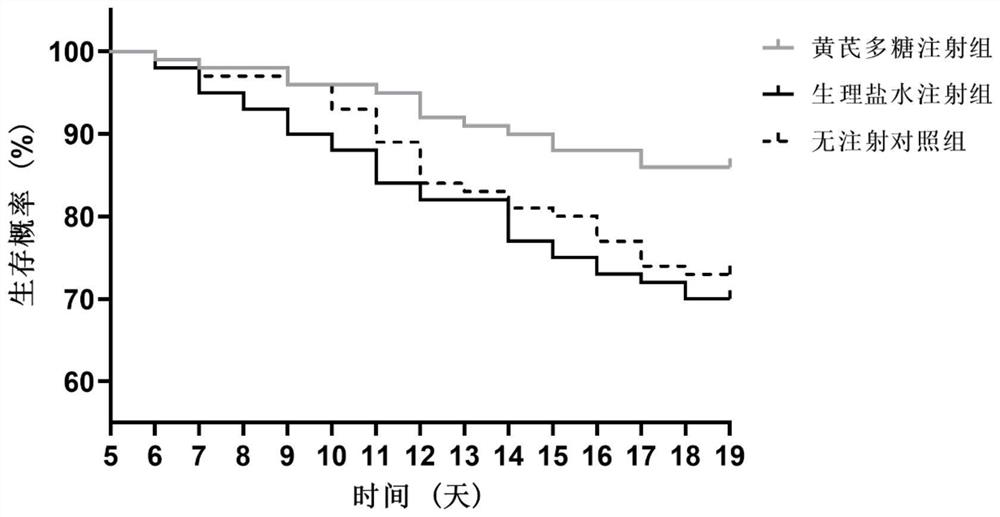

Intra-ovum injection for improving salmonella resistance of newborn poultry and application

PendingCN113577095AImproves resistance to SalmonellaImprove immunityAntibacterial agentsOrganic active ingredientsBiotechnologyAstragalus polysaccharide

The invention belongs to the technical field of agricultural animal husbandry production, and particularly relates to an intra-ovum injection for improving the salmonella resistance of newborn poultry and the application of the intra-ovum injection. The technical problem to be solved by the invention is to provide the in-ovum injection which is used for poultry embryos, has small toxic and side effects and no drug residue and is used for preventing newborn poultry from being infected with salmonella and the application of the intra-ovum injection. The intra-ovum injection comprises the following active ingredient: astragalus polysaccharide. The injection provided by the invention can effectively improve the development and maturation speed of immune organs of newborn poultry and improve the capability of resisting salmonella of poultry infected within one week old, and has a better effect of preventing infection of newborn poultry than conventional astragalus drugs.

Owner:PANZHIHUA UNIV

Beehive used for producing mature honey and method used for producing mature honey

Embodiments of the invention relate to the technical field of bee breeding, and provide a beehive used for producing mature honey. The beehive used for producing the mature honey comprises a first beehive body, a second beehive body and vertical queen bee isolation plates, wherein the beehive has a honey flowing state configuration; in the honey flowing state configuration, the vertical queen beeisolation plates are detachably arranged in the first beehive body and divide the first beehive body into breeding areas and honey storage areas; at least one second beehive body is detachably arranged on the top surface of the first beehive body in an overlapped mode; and the interior of at least one second beehive body communicates with the honey storage areas and is isolated from the breeding areas through the vertical queen bee isolation plates. According to the beehive used for producing the mature honey provided by the embodiments of the invention, the vertical queen bee isolation platesare arranged in the first beehive body, so bees can produce, make honey and store the honey in the honey storage areas of the first beehive body and at least one overlapped second beehive body; the honey collecting and honey making efficiency is improved; the maturing speed of the honey is increased; and the yield of mature honey is increased.

Owner:BEE RES INST CHINESE ACAD OF AGRI SCI

High-yield planting method for ginger

InactiveCN107493949AGuaranteed disease-freeIncrease growth rateSeed and root treatmentFertilising methodsBudDisease free

The invention relates to a high-yield planting method for ginger. The high-yield planting method comprises the following steps: land selection, seed selection, seeding, fertilization, management and harvesting. According to the high-yield planting method, old ginger with favorable quality serves as ginger seeds, together with disinfection treatment, the ginger seeds are disease-free to an utmost extent, and a foundation is laid for planting high-yield ginger. Planting is performed through reasonable bud forcing treatment, and fertilization is performed according to different growth stages, so that sufficient nutrition is provided for the whole growth process of ginger, and the growth speed and the maturation speed of ginger are improved. Through later disease management, harms of pests and diseases to the yield of ginger are avoided, and such harms as root burning and rotting of ginger can be effectively prevented. Ginger planted by the method has the characteristics of big piece, good quality and high yield.

Owner:桐梓县小水芦柑专业合作社

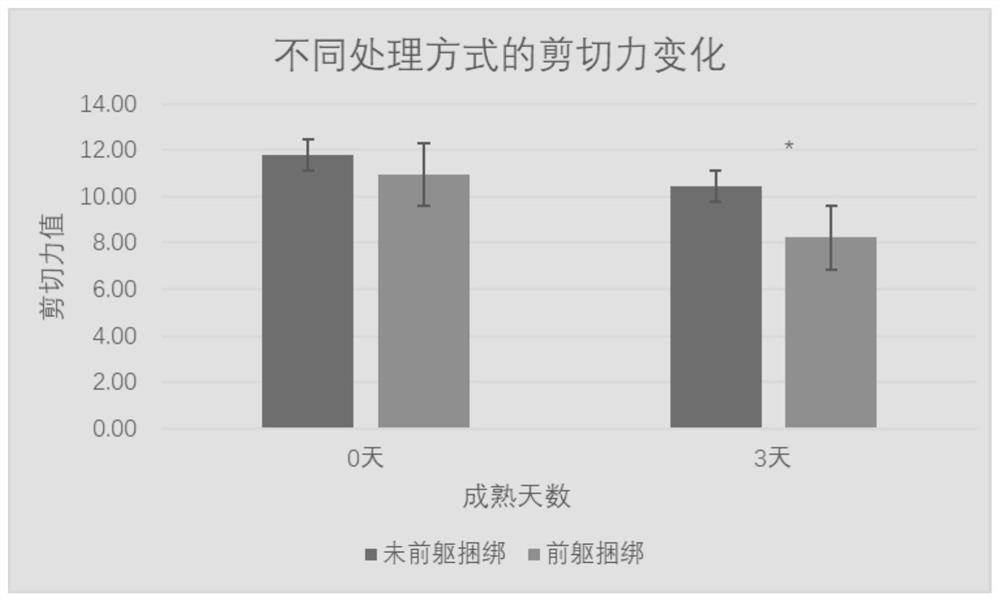

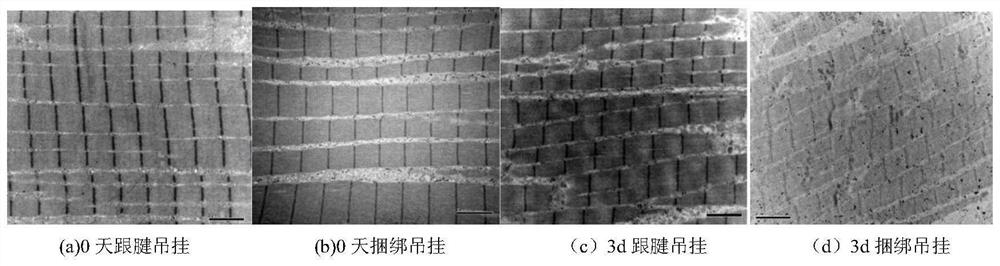

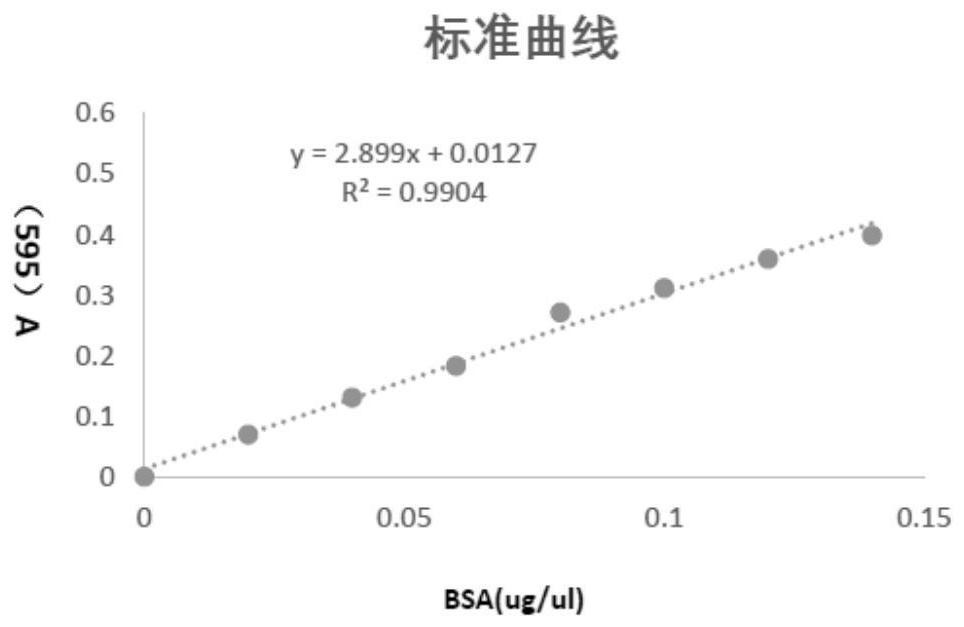

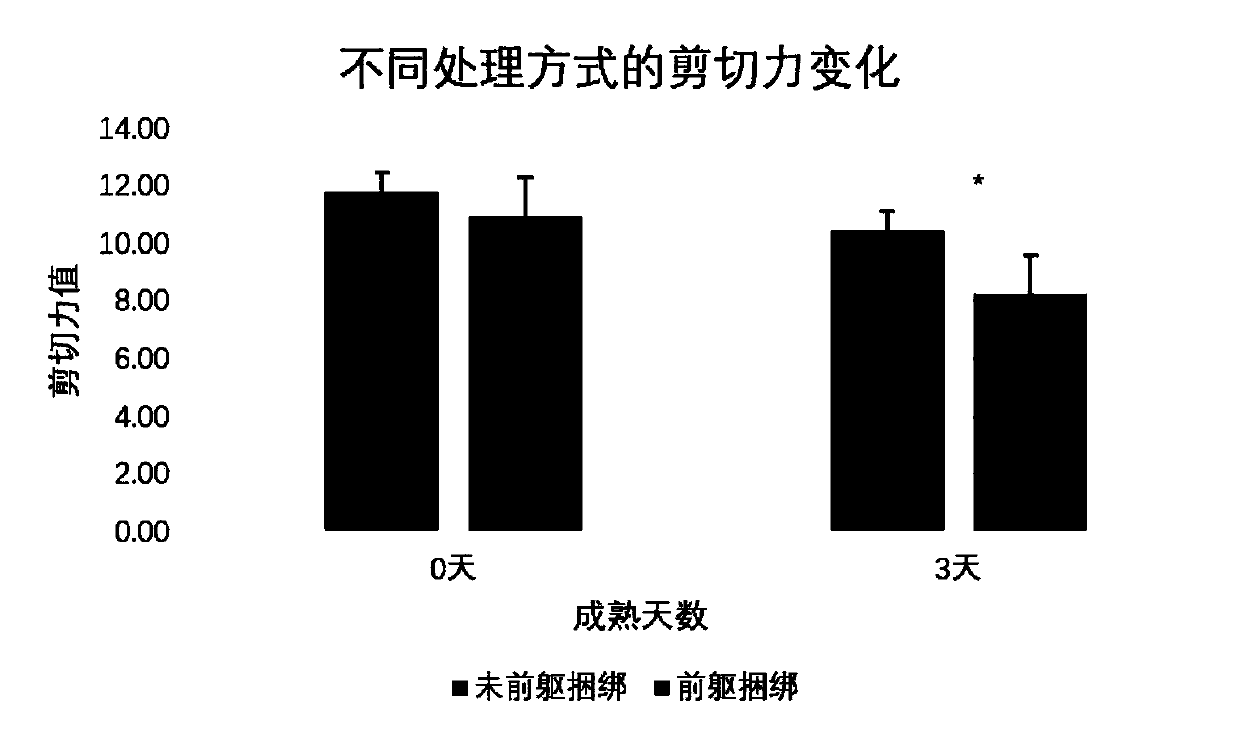

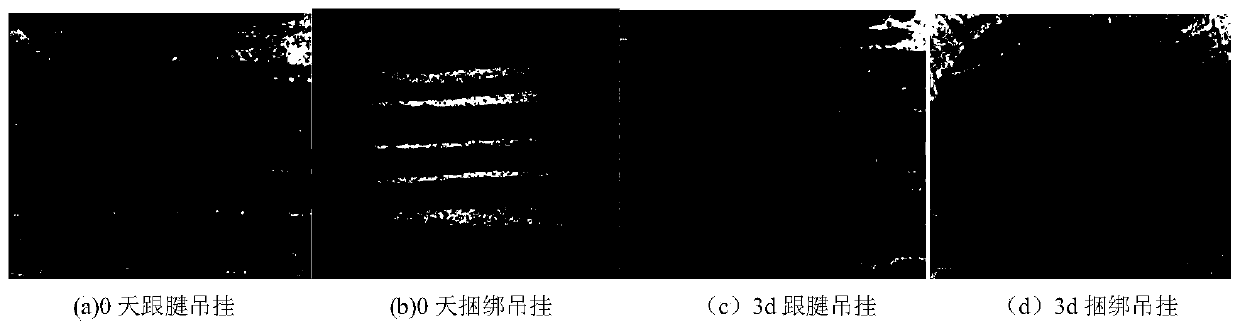

A Method for Accelerating Post-mortem Maturity of Beef Cattle

ActiveCN110419557BAccelerate the speed of maturationFragmentation index risesMeat/sausage hanging-upMeat processing devicesSpinal columnMuscle contraction

Owner:INST OF ANIMAL SCI OF CHINESE ACAD OF AGRI SCI

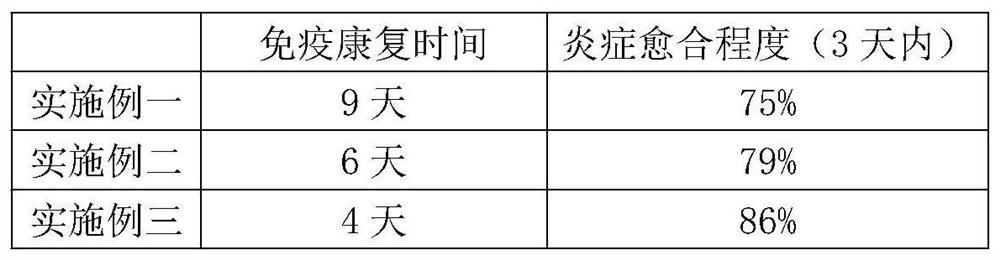

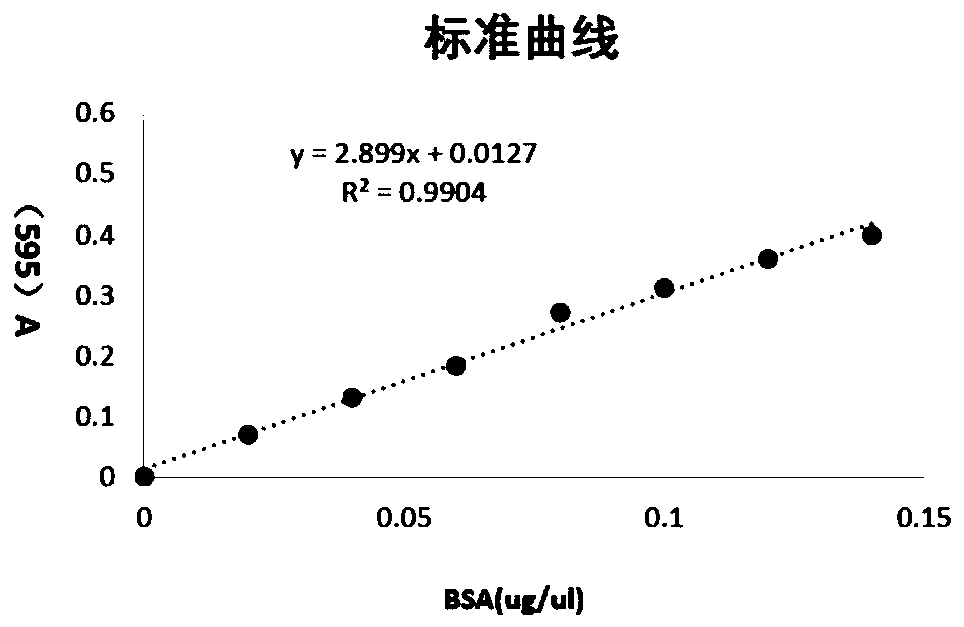

Novel leukocyte extract mixed factor and preparation method thereof

InactiveCN112843237AIncrease the number of generatedAccelerate the speed of maturationPeptide/protein ingredientsAntipyreticImmunocompetenceWhite blood cell

The invention discloses a novel leukocyte extract mixed factor which comprises the following components in percentage by volume: 15-27 parts of leukocyte extract, 25-33 parts of platelet lysate, 5-10 parts of interleukin, 22-25 parts of stem cell extract and 5-23 parts of leukocyte increasing substance. The invention also discloses a preparation method of the novel leukocyte extract mixed factor. The preparation method comprises the following steps: S1, preparing the leukocyte extract; S2, preparing a platelet lysate; S3, preparing a mixed factor; and S4, drying a finished product; the leukocyte increasing substance is added into the leukocyte extract, so that after mixed factors enter animal bodies on the basis of healing of the leukocyte extract, the generation quantity of leukocytes and the maturation speed of the leukocytes are increased, and inflammation healing and immunocompetence regulation are accelerated; in the preparation process of the mixed factor, the leukocyte is cultured to supplement nucleotide and leukocyte factors, so that the powder yield of the mixed factor can be increased, the treatment effect can be improved, and the treatment effect can be more stably exerted.

Owner:宏之俊生物科技(上海)有限公司

Nutrition composite rice capable of relieving summer heat and preparation method thereof

The invention relates to a nutrition composite rice capable of relieving summer heat and a preparation method thereof. The nutrition composite rice comprises the following raw materials by weight: 30 to 40% of rice flour, 5 to 15% of soybean meal, 10 to 20% of mung bean meal, 5 to 10% of wheat flour, 5 to 10% of sweet rice flour, 4 to 12% of white gourd powder, 5 to 11% of water chestnut powder, 5 to 10% of pearl barley meal, 2 to 5% of lotus leaf powder, 1 to 4% of cassia seed powder, 3 to 5% of chrysanthemum powder, 0.12 to 0.36% of xanthan gum and 0.07 to 0.29% of konjac glucomannan. The preparation method comprises the following steps: 1) removing impurities in the raw materials, crushing and sieving the raw materials and weighing and mixing the raw materials in proportion; 2) adding a proper amount of drinking water and carrying out mechanical stirring so as to realize uniform mixing; 3) processing an obtained mixture with an extrusion-expansion machine and a pelletizer so as to realize curing and non-puffing and preparing rice-like composite rice by using a forming die and a rotary cutting knife; and 4) carrying out drying, polishing, impurity removal, grading and packaging. The jade green nutrition composite rice capable of relieving summer heat provided by the invention can relieve summer heat and remove fire, is suitable for being eaten in summer and has reasonably collocated nutrient elements and cooking characteristics of natural rice; and visco-elastic performance of cooked rice and adhesiveness of rice gruel made from the composite rice are good, and the cooked rice and the rice gruel has good taste, colors and the like.

Owner:TIANJIN UNIV OF SCI & TECH

Method for planting snakegourd

PendingCN109042138AFast growthAccelerate the speed of maturationFruit crop cultivationOverwinteringSite selection

The invention relates to a method for planting snakegourd. The method comprises the following steps of (1) site selection; (2) soil preparation; (3) scaffolding; (4) field planting; (5) topdressing; (6) fruit promoting; (7) overwintering; (8) harvesting. The method can effectively increase the growth rate of the snakegourd, improve the ripening speed, yield and size of fruits, can avoid the injuryand death of freezing of the snakegourd in the winter, achieve the standardized planting of the snakegourd, and be beneficial to the healthy development of the industry.

Owner:长沙县启沃种养专业合作社

A kind of preparation method of broad bean paste

ActiveCN107981219BExtended shelf lifeFirmly lock in nutrientsFood ingredient as antioxidantFood preservationBiotechnologyMicroorganism

The invention provides a method for preparing broad bean paste, which comprises the following steps: A. making broad bean paste from dried watercress; B. making soup with chunyang bark, purple bark, fennel and water; , oily camphor leaves, fragrant leaves, pumpkin leaves are layered and covered for the first fermentation; D, remove the ash and impurities; E add salt and soy sauce for the second fermentation; F, add pepper, kaempferen and third fermentation ingredients for three times Fermentation; G prepare another main ingredient for pickling; H, mix the triple-fermented watercress, main ingredients for pickling, soy sauce, garlic, etc.; I, prepare chili oil, and mix it with the mixture obtained in step H to obtain final product. The invention can effectively control the peculiar smell produced by multiple natural fermentations, reduce water loss, promote the full reaction of microorganisms, and the product has bright color and rich sauce aroma.

Owner:平昌县文家何大妈食品有限公司

Salmon parent fish raising maturing method

InactiveCN103004673AGood qualityShorten storage timeClimate change adaptationPisciculture and aquariaBroodstockMorning

The invention relates to a salmon parent fish raising maturing method and aims to solve the problem that the existing salmon parent fish raising methods are long in raising time and low in raising survival rate. The method includes the steps of firstly, setting a female fish purse net area, a male fish purse net area and an empty purse net area; secondly, setting a drain holding net; thirdly, placing female fish and male fish respectively; fourthly, cleaning attachment on the purse net and the drain holding net in each morning and at each night; fifthly, detecting parent sexual gland maturity in each morning and at each night, taking out mature parent fish for manual reproduction, and placing immature parent fish in the empty purse net area; when a net area adjacent near the empty purse net area is inspected, inspecting the next adjacent purse net area until all the purse net areas are inspected, and accordingly the salmon parent fish raising maturing method is finished. The salmon parent fish raising maturing method is suitable for the field of aquatic products.

Owner:HEILONGJIANG RIVER FISHERY RES INST CHINESE ACADEMY OF FISHERIES SCI

Method for accelerating ripening of beef cattle after slaughter

ActiveCN110419557AAccelerate the speed of maturationFragmentation index risesMeat/sausage hanging-upMeat processing devicesLongissimusCalcaneal tendons

The invention discloses a method for accelerating ripening of beef cattle after slaughter. The method comprises the following steps: using a mode of calcaneal tendon hanging-neck arm binding to maturethe beef, and then improving the beef quality; the mode of calcaneal tendon hanging-neck arm binding meaning using a mode of calcaneal tendon hanging to hang the beef semi-carcass, and then applyinga radial pulling force between the distal end of the forearm and the neck of the beef; the radial pulling force being 10-50 KG; and the beef quality referring to the tenderness of the beef. Accordingto the present invention, the contraction of the longissimus dorsi muscle in the process of cadaveric stiffness can be inhibited by the method, the hind leg and the muscles along the spine can be in astraightened and slightly stretched state, the contraction of the longissimus dorsi muscle can be reduced, the length of sarcomere can be increased, the diameter of muscle fiber can be reduced, the tenderness of products is good, and the consistency of the tenderness is improved.

Owner:INST OF ANIMAL SCI OF CHINESE ACAD OF AGRI SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com