Synthetic method for cationic surface sizing agent

A surface sizing agent, cationic technology, applied in the field of polymer compound synthesis, can solve the problems of increasing the use of chemicals in the pulp system, demanding production process equipment, affecting paper drainage and forming, and improving the Cobb value. , The effect of reducing paper lint and powder and improving retention rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

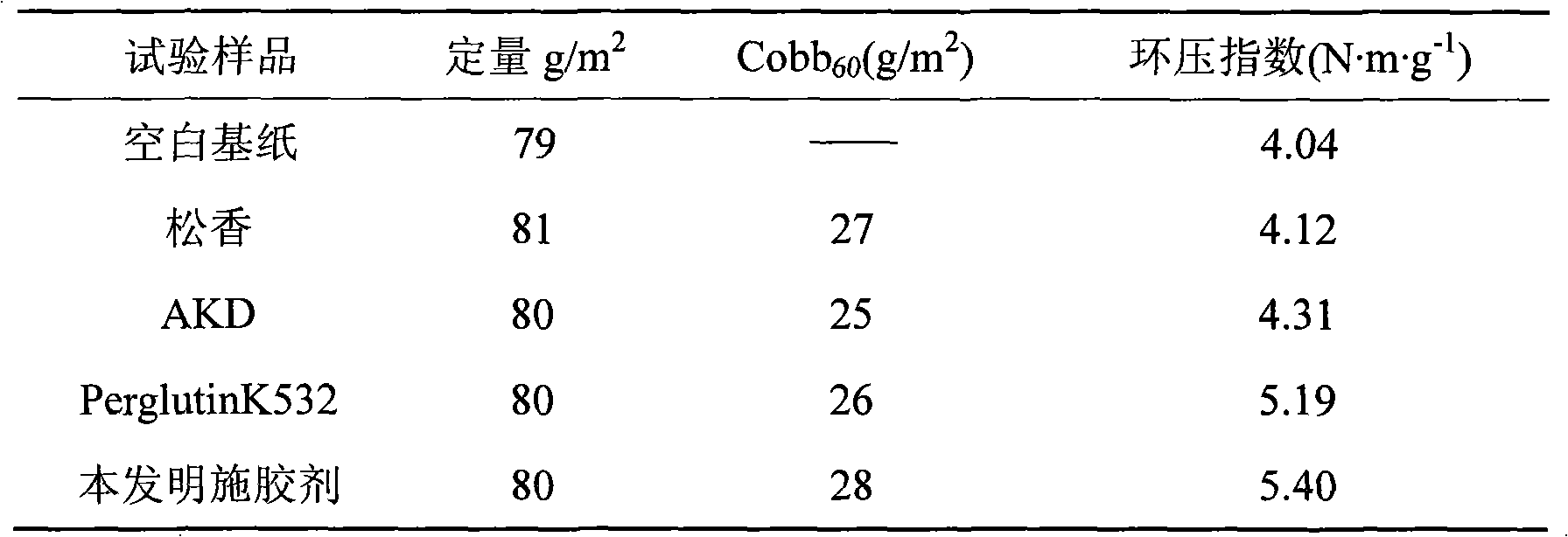

Embodiment 1

[0039] Weigh 1.5g tert-butyl peroxypivalate, dissolve in 75.0g acetic acid, then weigh 400.0g acetic acid, 80.0g styrene, 30.6g methyl methacrylate, 16.1g hydroxyethyl acrylate and 31.8g N, N-dimethyl hydroxyethyl (meth) acrylate, 16g methacryloyloxyethyltrimethyl ammonium chloride, 0.8g 3-hydroxyl-2-methylpropene, add in the 1000ml glass flask successively, And be warmed up to 157 ℃, slowly add 40g in the acetic acid solution that dissolves the tert-butyl peroxypivalate prepared above in the flask within 15min after starting to reflux, after keeping warm for 30min, the remaining tert-butyl peroxypivalate acetic acid After the solution was added dropwise within 90 minutes, continue to keep warm for 120 minutes, keep the system boiling, adjust the vacuum degree in the flask to -0.095 Mpa, remove excess acetic acid, reduce the temperature of the reaction system to 80 ° C, add 390.5 g of deionized water, and adjust the temperature with acetic acid. When the pH value reaches 3.2, ...

Embodiment 2

[0041] Weigh 6.5g peroxydicarbonate, dissolve in 300g ethanol, then weigh 100g ethanol, 95g styrene monomer, 90g methyl methacrylate monomer, 60g methacryloyloxyethyltrimethyl chloride Add ammonium chloride and 5g of allylamine into a 1000ml glass flask in turn, and heat up to 140°C. Slowly add 150g of the above-prepared ethanol solution in which peroxydicarbonate is dissolved in the flask within 10 minutes after the start of reflux, and keep warm for 30 minutes. Finally, drop the remaining ethanol solution of peroxydicarbonate in 120min, continue to keep warm for 150min, keep the system boiling, adjust the vacuum degree in the flask to -0.015Mpa, remove excess ethanol, and reduce the temperature of the reaction system to 80 ℃, add 578.5g deionized water, adjust the pH value to 3.2 with acetic acid, stir for 15min, and discharge at 40℃ to obtain a cationic polystyrene-acrylate surface sizing agent.

Embodiment 3

[0043] Weigh 3g of tert-butyl peroxypivalate, dissolve it in 150g of propionic acid, then weigh 300g of propionic acid, 60g of styrene monomer, 60g of hydroxyethyl acrylate monomer, and 24g of dimethylaminopropylene acrylamide , 3g of ethanolamine, sequentially added to a 1000ml glass flask, and heated up to 170°C, within 20min after the start of reflux, slowly add 90g of the propionic acid solution in which tert-butyl peroxypivalate prepared above was dissolved in the flask, and keep warm for 30min, Add the remaining propionic acid solution of tert-butyl peroxypivalate dropwise within 60 minutes, continue to keep warm for 100 minutes, keep the system boiling, adjust the vacuum degree in the flask to -0.010Mpa, remove excess propionic acid, and reduce the reaction system When the temperature reaches 80°C, add 337.5g of deionized water, adjust the pH value to 3.2 with acetic acid, stir for 15 minutes, and discharge at 40°C to obtain a cationic polystyrene-acrylic surface sizing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com