Circulation type energy-saving and water-saving food steamer

A circulating, steamer technology, applied in the field of steamers, can solve the problems of food condensation water damage, slow steam flow, steam overflow, etc., to maintain nutrition and taste, speed up ripening, and save energy and water.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

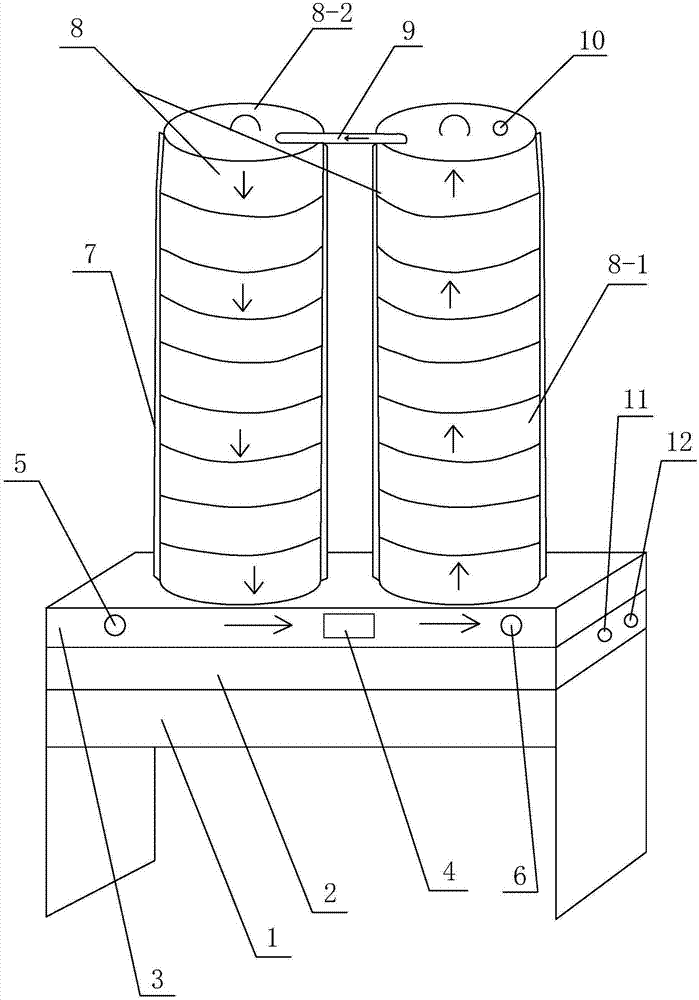

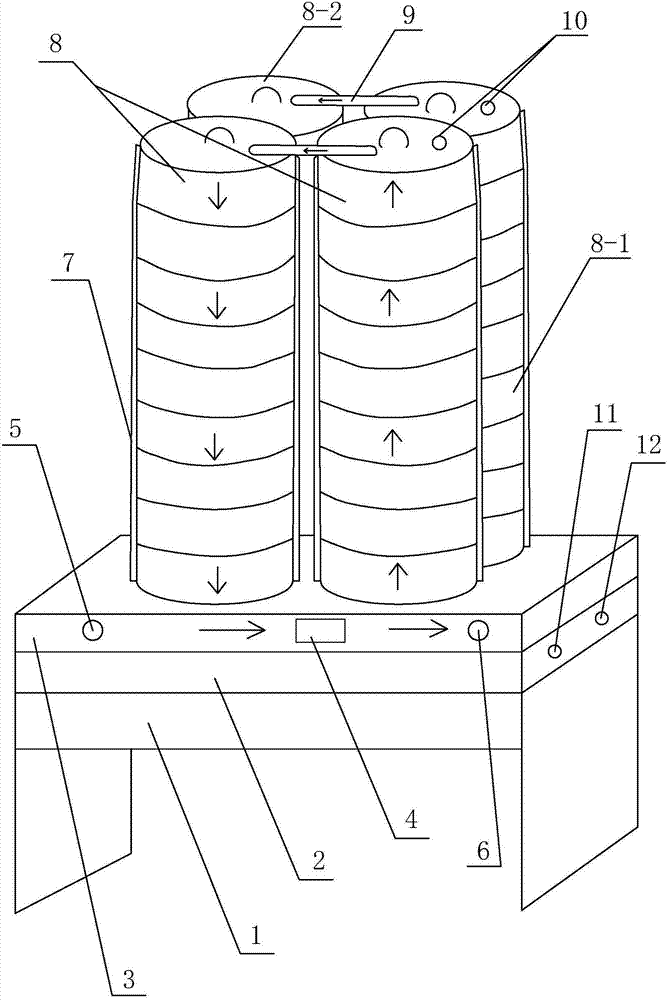

[0028] The circulating energy-saving and water-saving steamer includes a steam oven 1, a steamer base 3 and an air extractor 4 arranged in the steamer base 3, the steamer base 3 is installed on the steam oven 1, and the steamer base 3 is also provided with an air intake valve 6 and exhaust valve 5, also includes steam storage box 2 and at least one group of steamer, described steam storage box 2 is arranged between steam oven 1 and steamer base 3, each group of steamer is a group with two steamer bodies 8, The heights of these two steamer bodies 8 can be equally high or not equally high, preferably equally high. The steamer body 8 is installed on the steamer base 3, and the two sides of each steamer body 8 are provided with fastening belts 7 for fixing the steamer body 8 along the vertical direction of the steamer body 8 from top to bottom. The number of groups of the steamer can be 1, 2 or any other positive integer, and the user can design the number of groups of the steamer...

Embodiment 2

[0034] Different from Example 1, the number of groups of the steamer is 2 groups, that is, it is composed of 4 steamer bodies, and every two steamer bodies 8 with the same height are a group, so that the steaming work of each group of steamer groups is independent of each other. , independent of each other, each group of steamers is separated when installed on the base.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com