Method for accelerating ripening of beef cattle after slaughter

A beef cattle and beef technology, applied in the direction of processing meat, slaughtering, meat processing equipment, etc., can solve the problems of waste of energy and resources, increase of production costs of enterprises due to ripening time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 1. Materials and methods

[0028] 1.1 Test material

[0029] Beef samples were taken from the Yixin Cattle and Sheep Breeding Professional Cooperative in Yining County, Xinjiang.

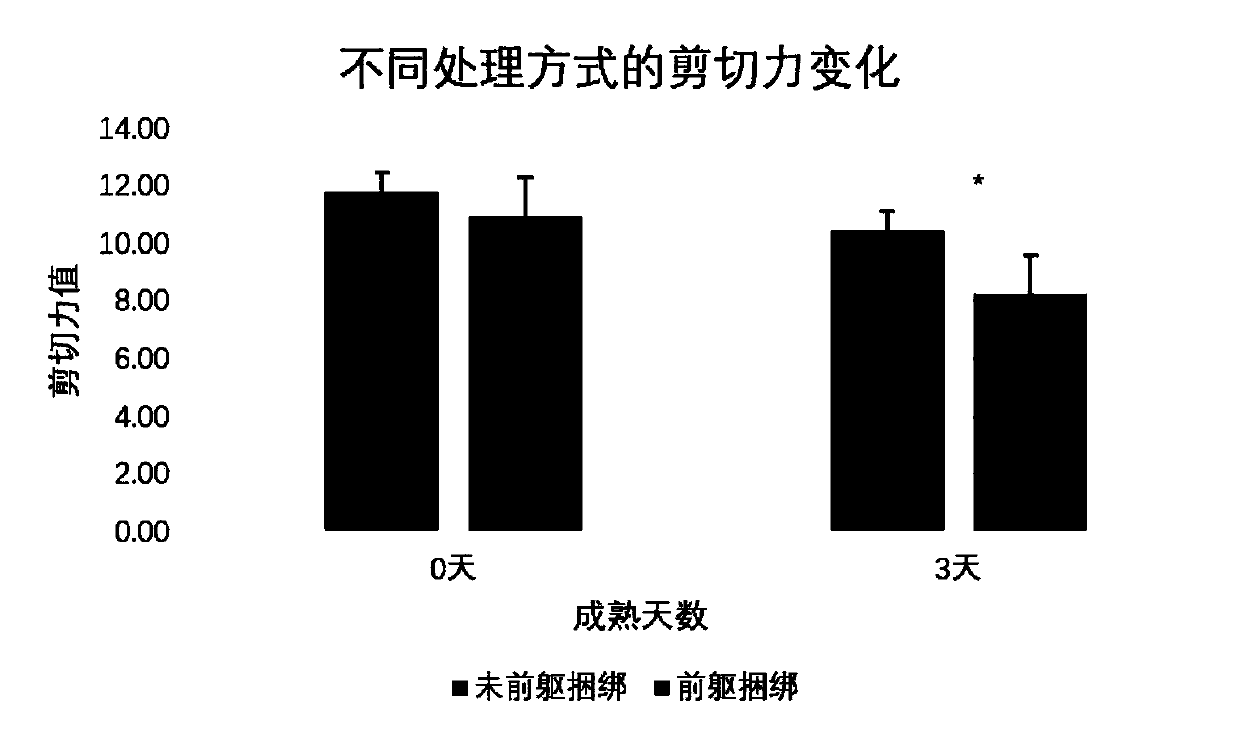

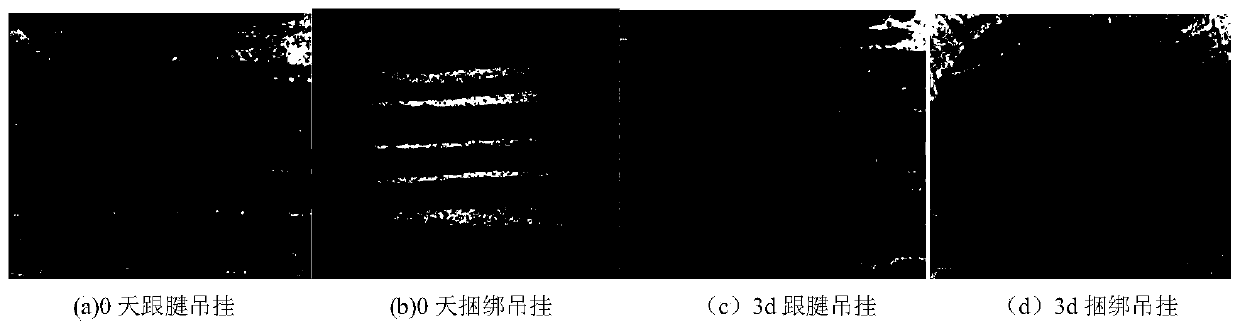

[0030] Six 30-month-old Xinjiang brown bulls (living mass: (566±32) kg) were selected. After slaughtering and division, the right half carcass was matured by ordinary Achilles tendon hanging method, and the left half carcass was matured by neck and arm restraint hanging method. That is, a radial tension of 30KG is applied to the junction of the distal forearm of the cow and the first and second cervical vertebrae of the cow, and the longissimus dorsi muscle samples are taken respectively at 1 hour and 72 hours after slaughter, and the samples are processed and stored according to the detection requirements of various specific indicators.

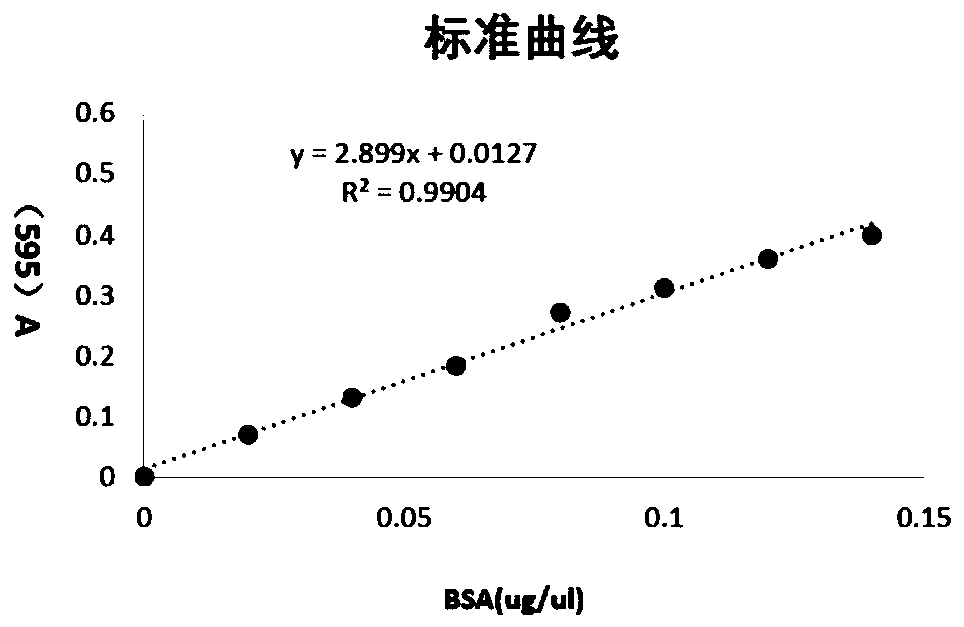

[0031] Test reagents: Potassium chloride, dipotassium hydrogen phosphate, potassium dihydrogen phosphate, magnesium chloride, sodium azide, ethylene glyco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com