Diamond-based ultraviolet detector and its preparation method

An ultraviolet detector, diamond technology, applied in semiconductor devices, final product manufacturing, sustainable manufacturing/processing, etc., can solve the problems of carrier drift and collection, thick overall thickness, affecting the number of carriers generated, etc. Achieve the effect of improving sensitivity and responsivity, increasing the number of production, and increasing the detection area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Method for preparing diamond-based ultraviolet detectors, including the following steps:

[0021] First, a diamond film 1 is provided, which may be a substrate prepared by a high temperature and high pressure process, or a substrate prepared by a CVD (chemical vapor deposition) process, and may also be self-supporting diamond film. The shape of the diamond thin film 1 is a rectangular, circular, elliptical or other shape. This embodiment is an example of a rectangular diamond film 1. Photolithography, etching process and its use devices are existing, and the raw materials used are purchased.

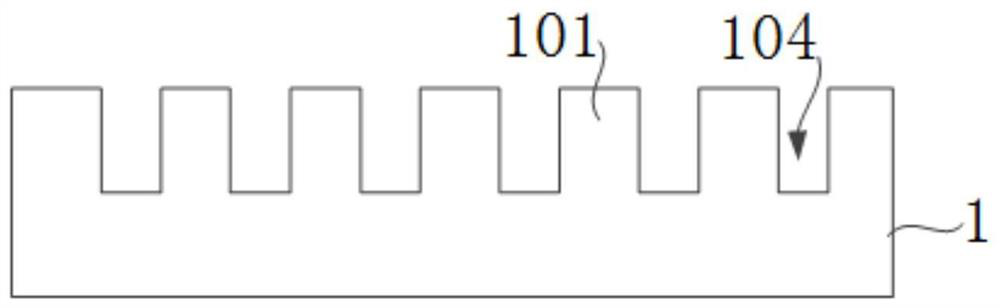

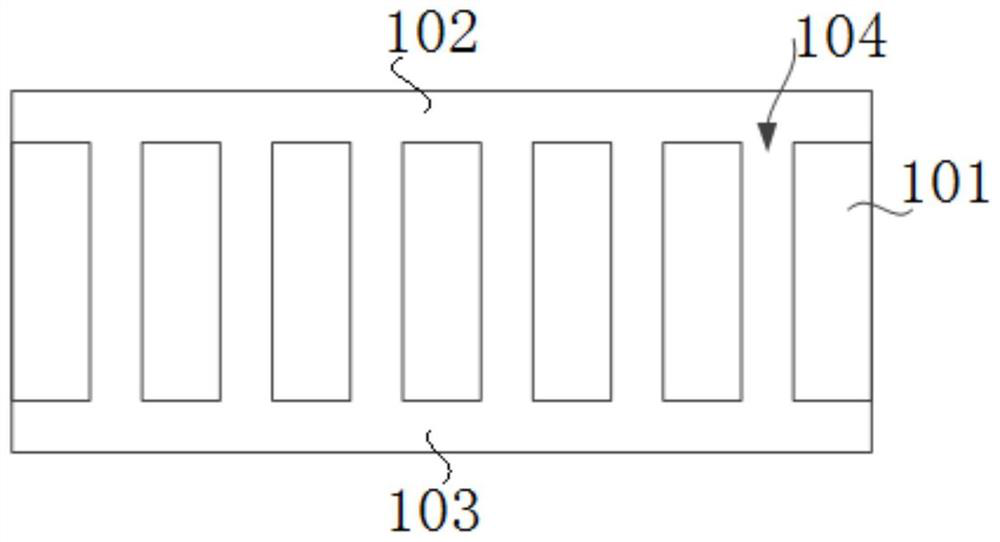

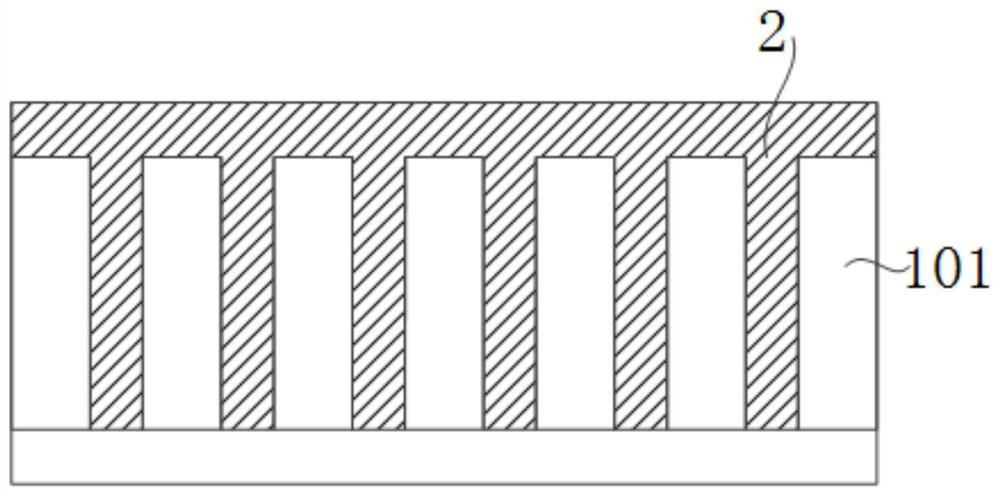

[0022] like Figure 1 ~ 2 Then, the diamond thin film 1 is etched to form a diamond micropper 101, and the voids between the diamond microcapstalk 101 constitute the third trench 104, the upper and lower sides of the third trench 104. There is a first trench 102, a second trench 103. Specifically, the periodic arrangement of diamond microcepusions 101 are obtained in the surface of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com