Hydraulic module for transmission

A hydraulic module and gearbox technology, which is applied to components with teeth, belts/chains/gears, mechanical equipment, etc., can solve problems that affect the shifting effect and cannot be controlled independently, so as to improve safety and reliability. Protect the mechanical structure and retain the effect of the control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

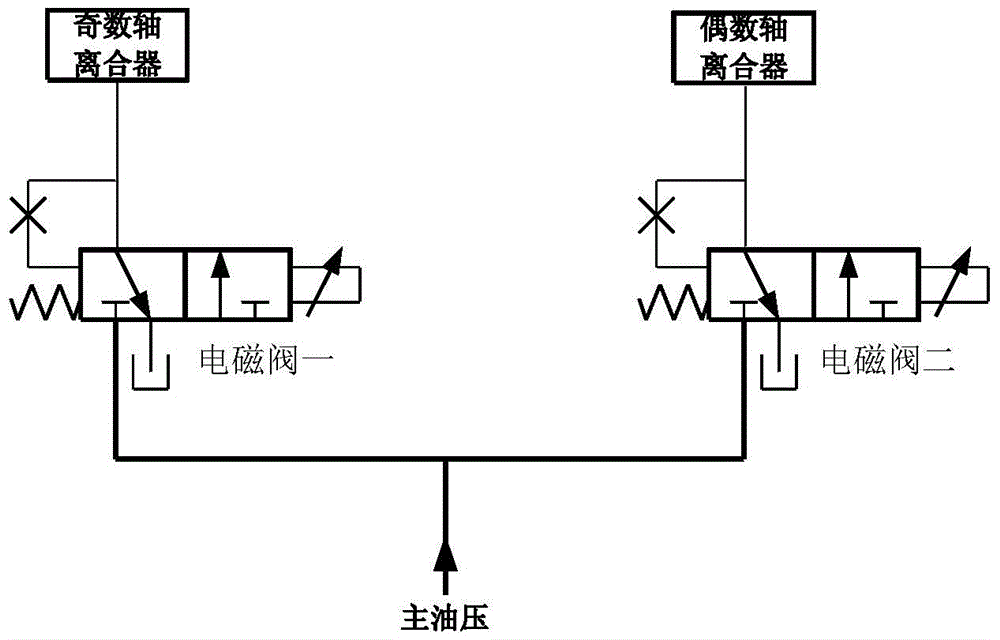

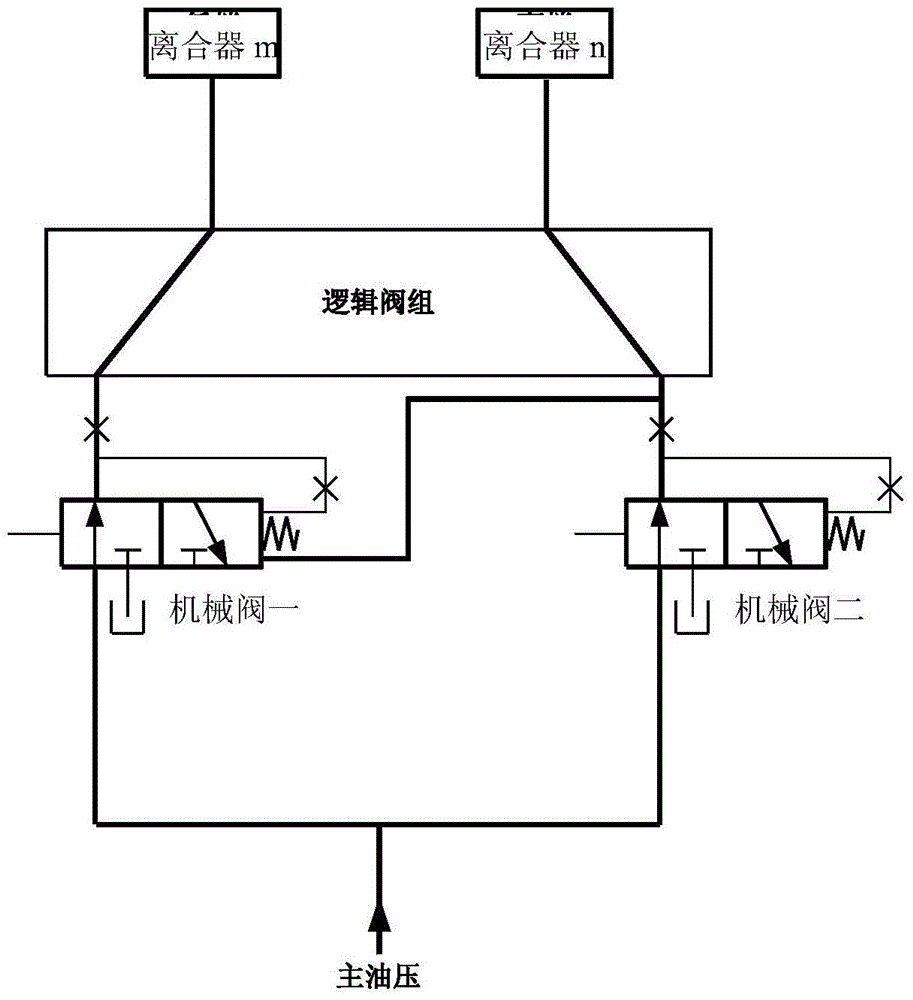

[0023] see image 3 , which is the hydraulic module of the gearbox of the present application, applicable to DCT or AT (if used for AT, the odd shaft clutch and the even shaft clutch should be changed to clutch m and clutch n). The shifting mechanism is jointly controlled by four electromagnetic valves and four mechanical valves and two clutches. The four solenoid valves are two proportional valves and two on-off valves, all of which are controlled by the TCU. The thick solid line indicates that there is a certain oil pressure in the oil circuit, and the thin solid line indicates that the oil pressure in the oil circuit is zero.

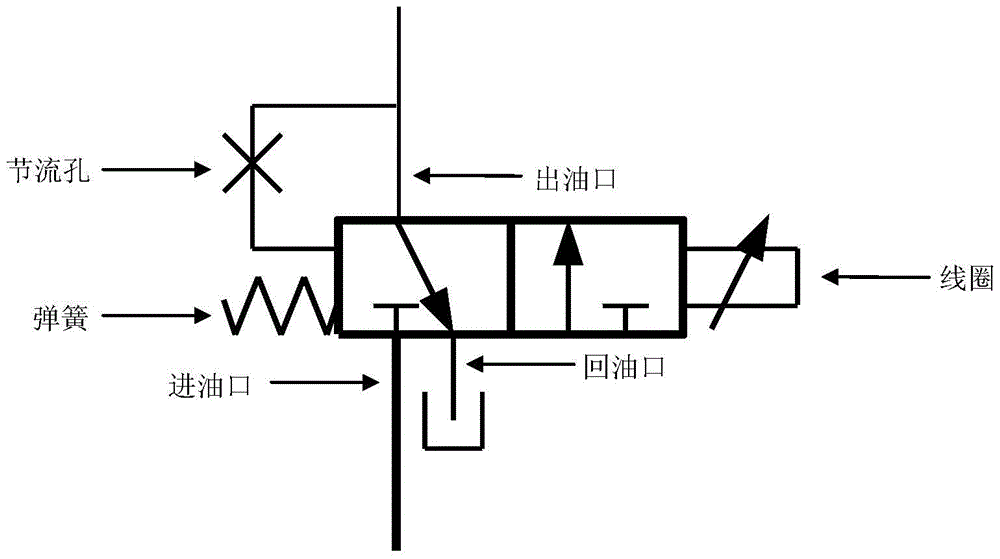

[0024] The proportional valve is as Figure 1a The two-position three-way solenoid valve shown, the two positions refer to the oil unloading state from the oil outlet to the oil return port, and the oil delivery state from the oil inlet to the oil outlet. The proportional valve can realize the oil pressure of the oil outlet. continuous adjustment....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com