Liftable power generator assembly with automatic braking function

An automatic braking and generator technology, applied in the direction of brakes, braking components, mobile frames, etc., can solve the problems of collision damage to the main equipment, increase the overall equipment volume, increase the complexity, etc., to avoid collision damage, practical Strong performance, simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

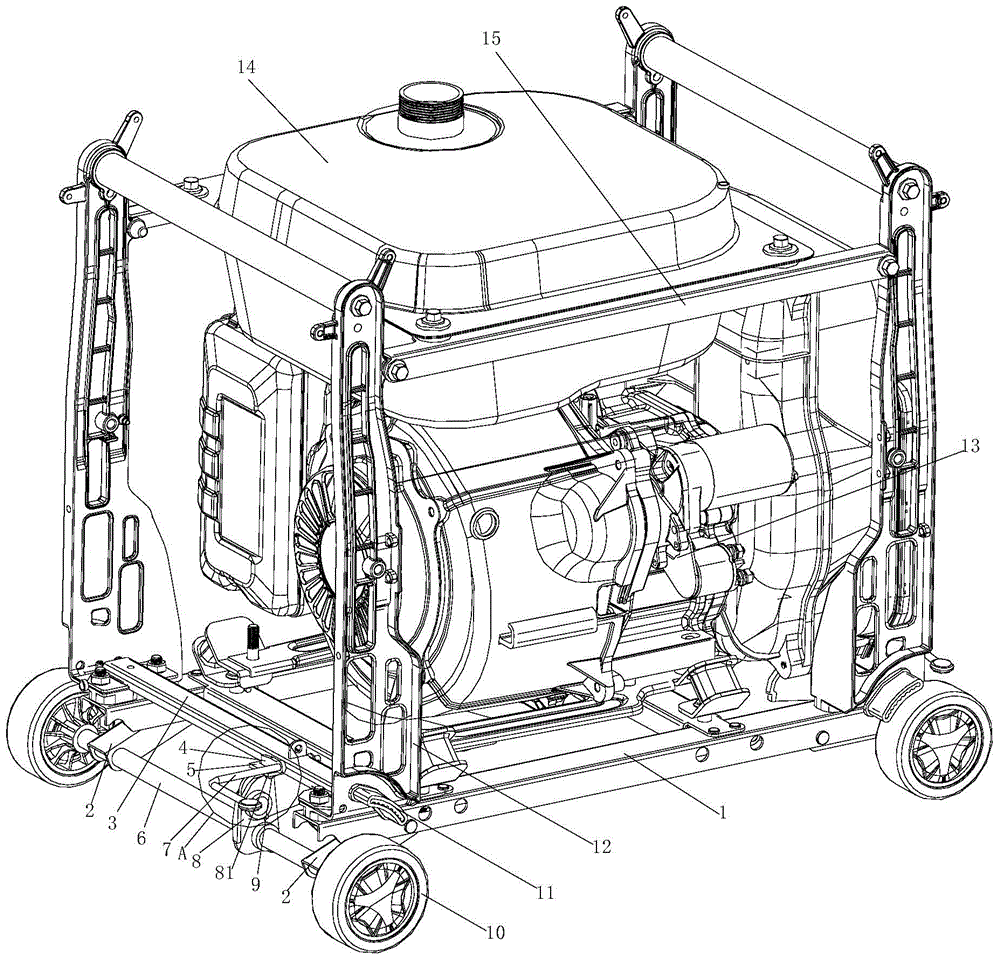

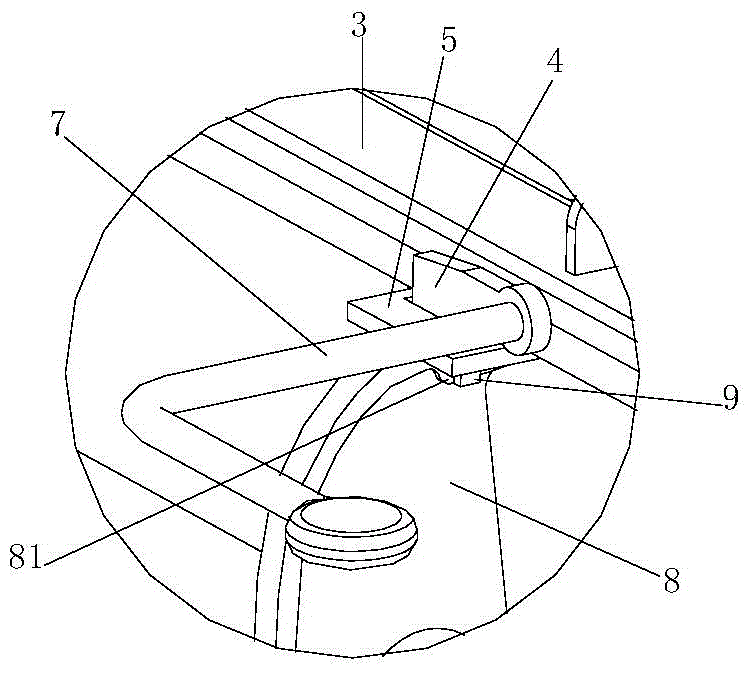

[0022] figure 1 It is a structural schematic diagram of the present invention, figure 2 for figure 1 The enlarged view at A, as shown in the figure: the liftable generator assembly with automatic braking in this embodiment includes main equipment and a rack assembly for installing the main equipment; the rack assembly includes a walking The wheel assembly and the bottom plate 1 used to install the main equipment, the bottom 1 plate is supported on the road wheel assembly through the lifting mechanism; the brake plate is installed on the frame, and the brake plate is from the radial outer edge from top to bottom Facing the walking rotating part of the walking wheel assembly, and the brake plate 11 brakes the rotating part when the base plate 1 is at a low point; the walking wheel assembly generally includes the walking wheel and the mounting parts, which will not be described in detail here; the lifting mechanism can be an existing Some ball screw mechanisms, casing mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com