Power assembly mounting structure

A powertrain and installation structure technology, applied in the direction of power plant, superstructure, substructure, etc., can solve the problems of cost increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

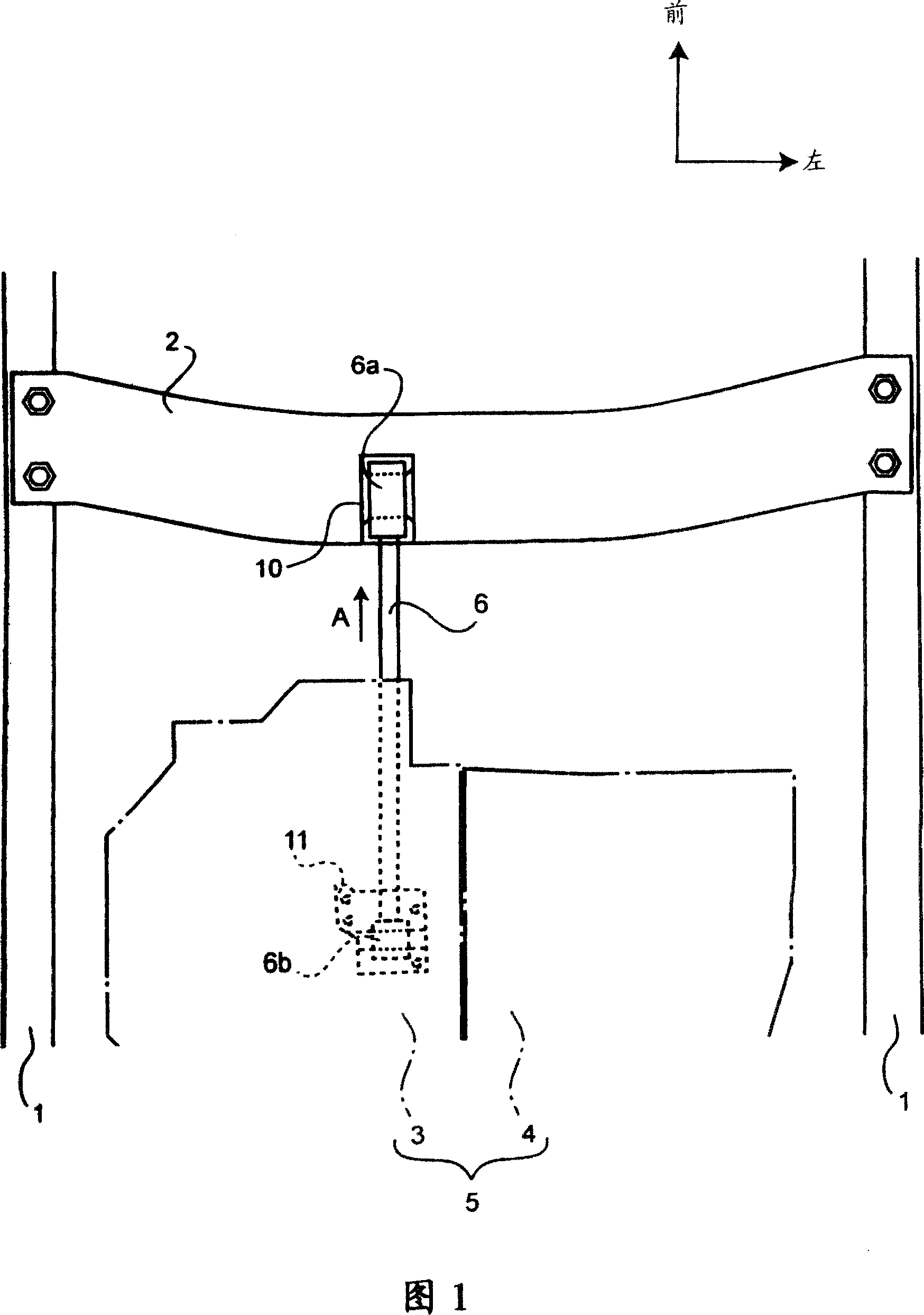

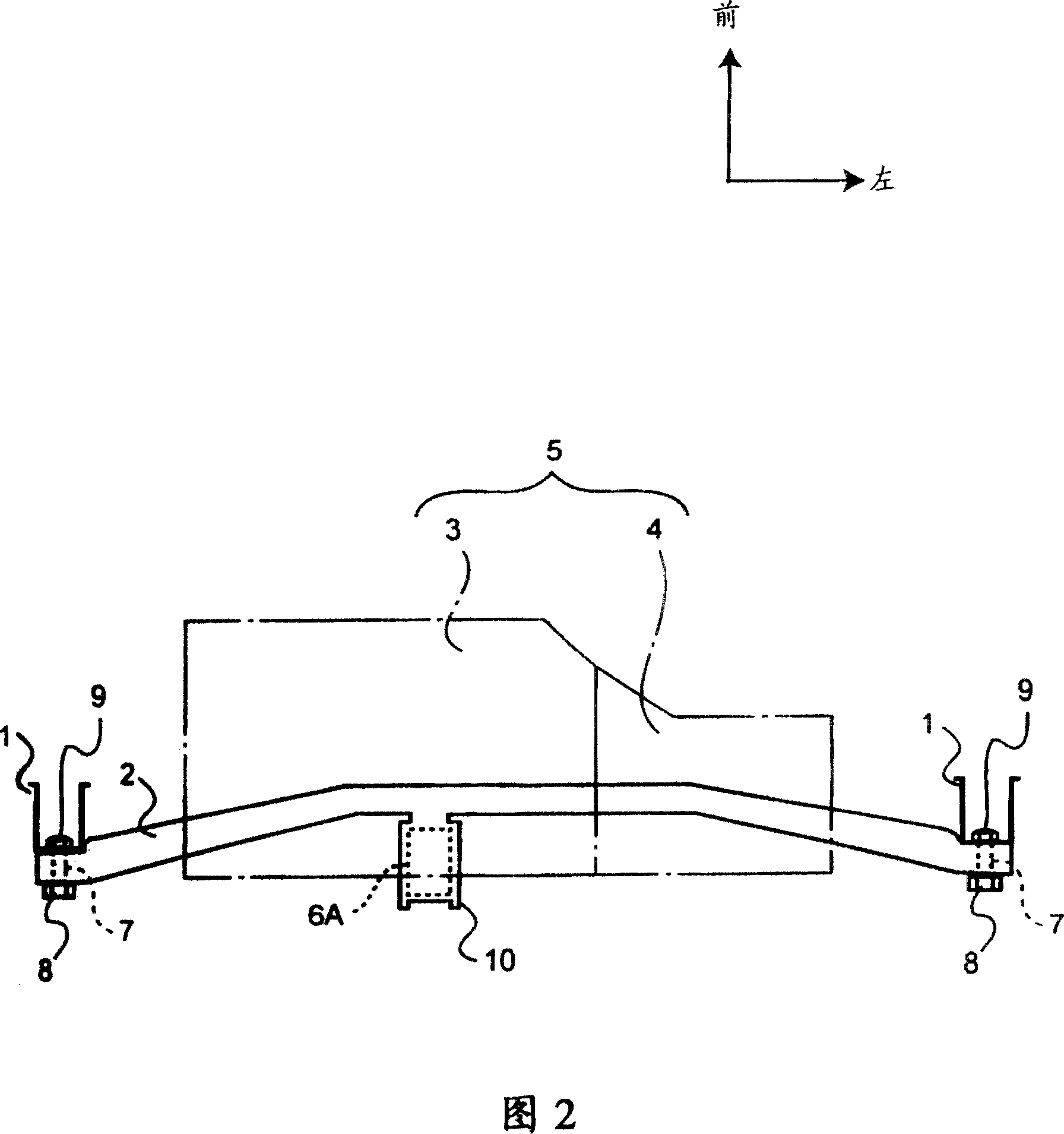

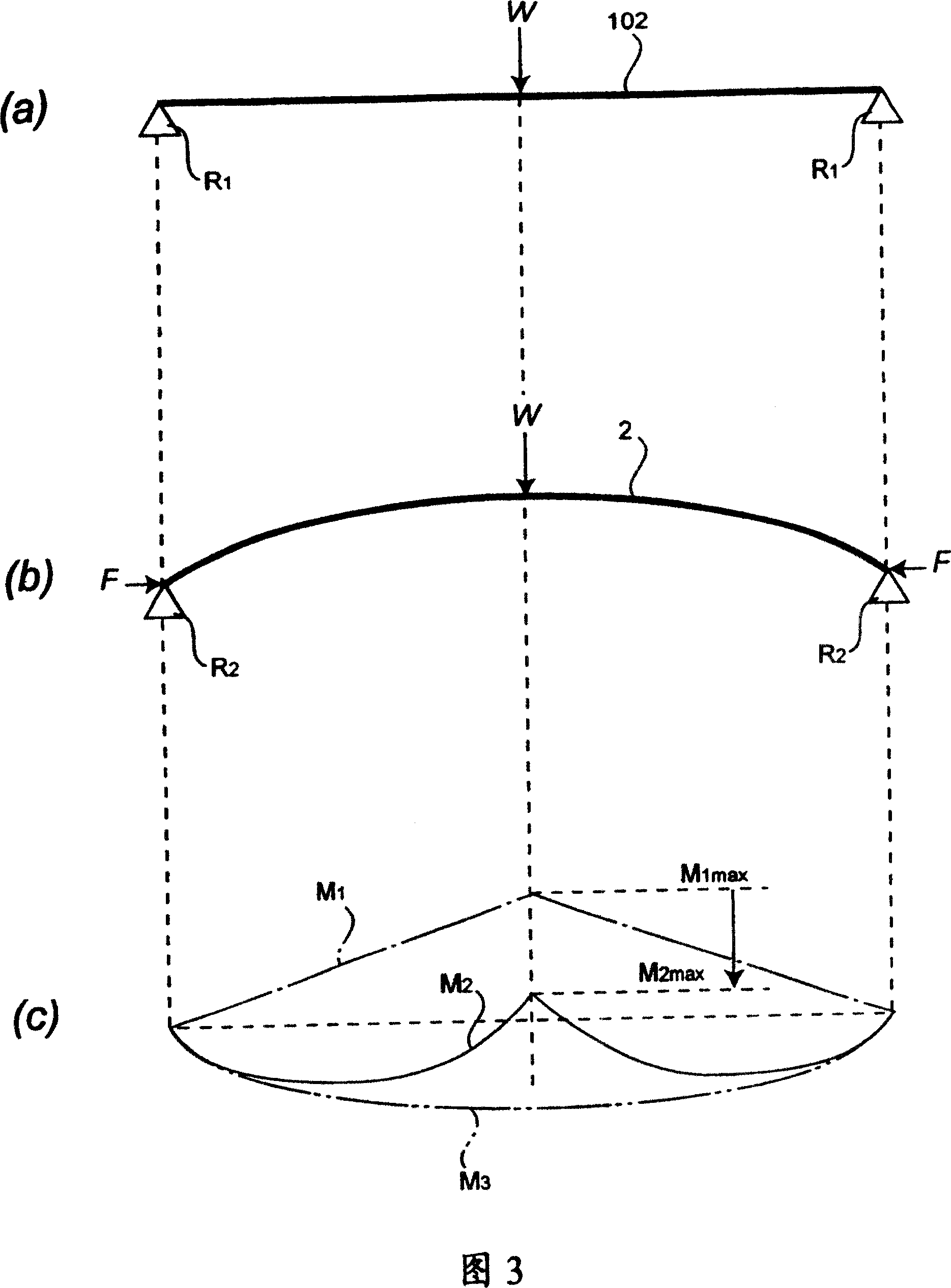

[0015] Referring to FIGS. 1 to 3 , a powertrain mounting structure according to the present invention will be described hereinafter. Fig. 1 is a plan view schematically showing the installation structure of the powertrain, Fig. 2 is a front view of the installation structure of the powertrain, and Fig. A schematic diagram of the state.

[0016] As shown in FIG. 1 , a pair of side beams 1 and 1 extend in the longitudinal direction of the vehicle, and a cross beam 2 is arranged in the transverse direction of the vehicle, and both ends of the cross beam are fixed to the aforementioned side beams 1 and 1 . Furthermore, a powertrain 5 composed of an engine 3 and a transmission 4 is located between the right side beam 1 and the left side beam 1 and behind the cross beam 2 . Furthermore, an anti-sway bar (rod) 6 is arranged between the crossbeam 2 and the powertrain 5 , thereby establishing a connection between the powertrain 5 and the crossbeam 2 .

[0017] In this structure, as s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com