Preparation method of TEM analysis sample

A sample and extension direction technology, applied in the preparation of test samples, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problem of incomplete acquisition of bridging defect morphology and position, integrated circuit short circuit, and difficulty in judging bridging defects The specific reasons for the formation and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

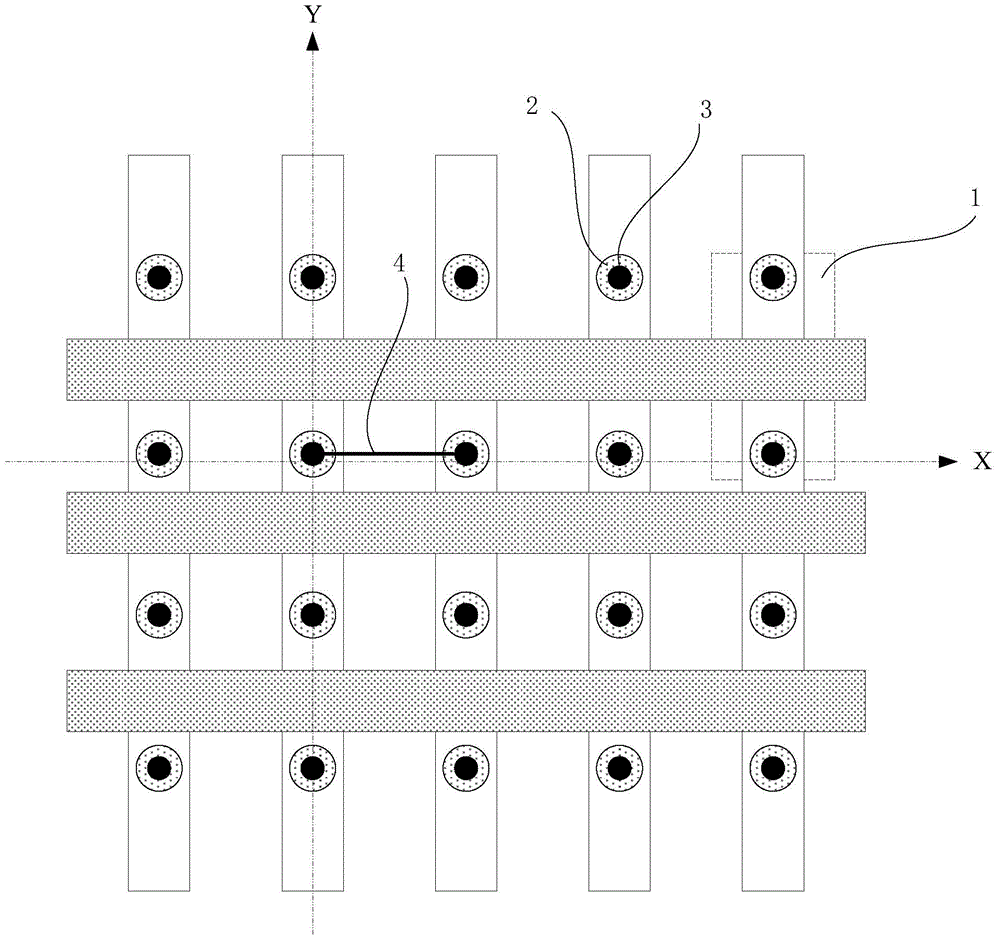

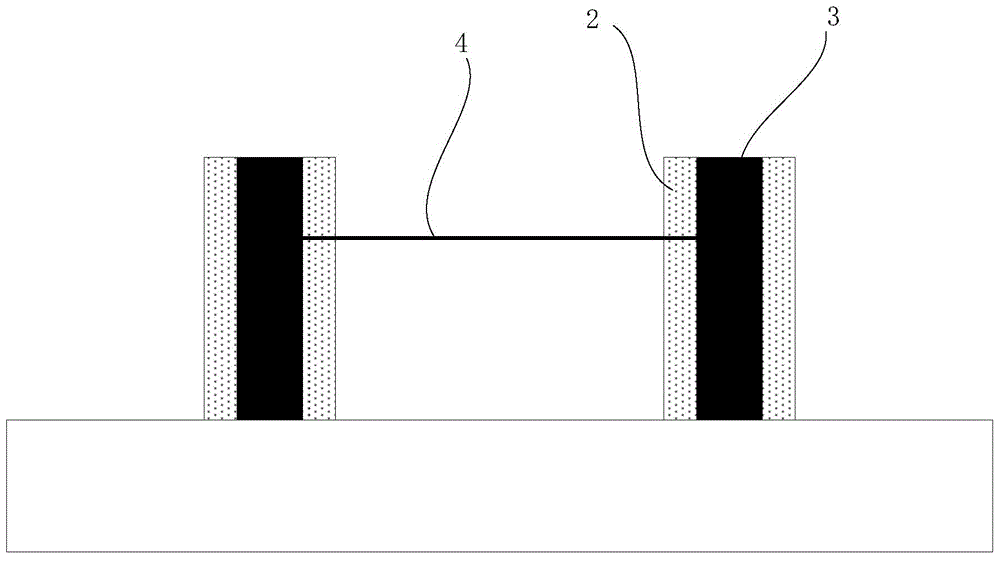

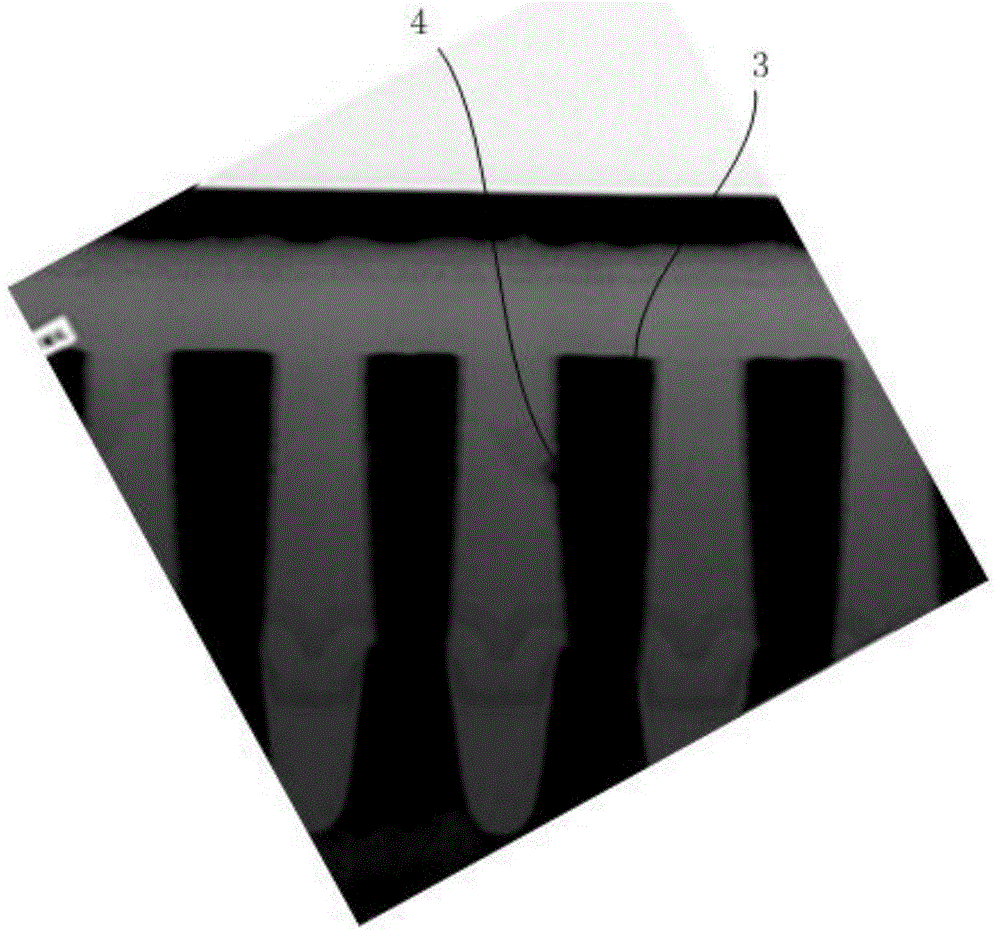

[0024] Such as Figure 4 As shown, the invention provides a kind of preparation method of TEM analysis sample, comprising:

[0025] providing a wafer to be inspected, the wafer is provided with a first contact hole structure and a second contact hole structure, and a bridging defect is formed between the first contact hole structure and the second contact hole structure;

[0026] cutting the first contact hole structure along a direction perpendicular to the extending direction of the bridging defect to obtain a first sample including a first cutting surface, the first cutting surface exposing the metal line of the first contact hole structure;

[0027] removing the metal lines of the first contact hole structure in the first cutting plane;

[0028] The first sample is cut along the direction perpendicular to the extending direction of the bridging defect to remove the second contact hole structure, and a sample for TEM analysis is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com