Method for evaluating service life of composite insulator

A composite insulator, service life technology, applied in measurement devices, material analysis through optical means, instruments, etc., can solve problems such as failure to meet power grid state evaluation, safe and reliable operation, and large proportions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0019] (1) Sampling:

[0020] Select the running composite insulator samples with different operation times from 1995 to 2010, clean the dirt on the surface of the outer shed with a brush, wipe the surface with absorbent cotton dipped in 75v% ethanol, let it stand to dry, and then the concentric circle position of the first shed at the high-voltage end Uniform sampling, five samples of 2×2cm for each composite insulator 2 Test points, vacuum dried and ready for use.

[0021] (2) ATR FTIR infrared spectrum detection

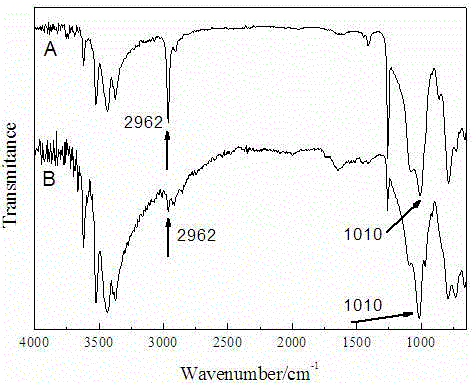

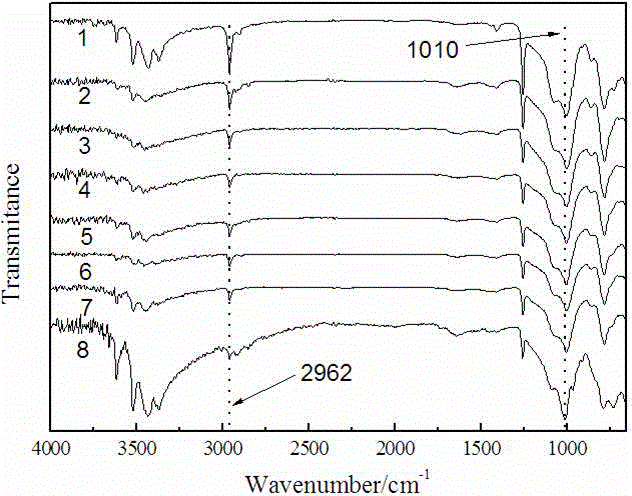

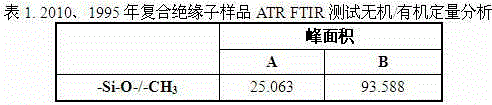

[0022] Taking the composite insulators put into operation in 1995 and 2010 as examples, the samples were detected by ATR FTIR, and the infrared spectrum images are as follows figure 1 shown. Peak at 2960cm -1 The position is an organic group (-CH 3 ) characteristic absorption peak, 1010 cm -1 The position is the characteristic absorption peak of the inorganic group (-Si-O-). Calculate the peak area of the two characteristic peaks according to the test resu...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap