Artificial hair and wigs using same

A technology of artificial hair and wigs, applied in the field of wigs, can solve the problems of labor and time consumption, poor curly hair styling, unnatural style, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1~ Embodiment 1-4

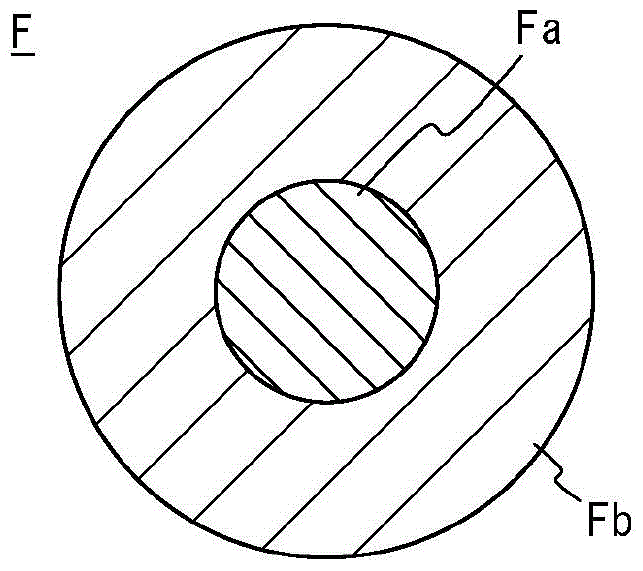

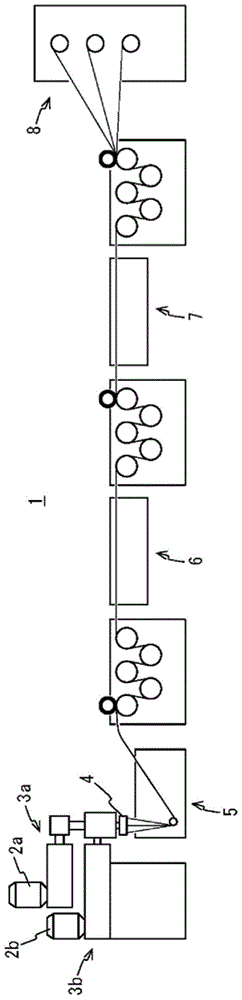

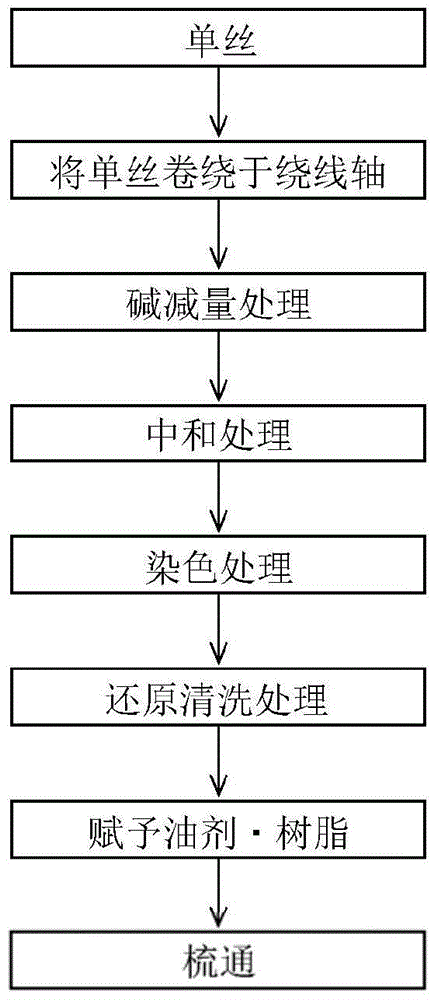

[0130] As the PET resin of the sheath component, MA-2103 (intrinsic viscosity: 0.68) manufactured by UNITIKA CO., LTD. was used. In addition, 5 parts by weight of a masterbatch containing 5% of silica manufactured by Tosoh Silica Co., Ltd. as a matting agent was prepared with respect to 95 parts by weight of the PET resin. Novaduran 5010L (intrinsic viscosity 1.0) (PBT resin) manufactured by Mitsubishi Engineering-Plastics Co., Ltd. was used as the core component. The extruder temperature of the sheath part was set at 285°C, the extruder temperature of the core part was set at 270°C, the PET resin and the PBT resin were melted, and the core / sheath weight ratio was respectively 5 / 95 (Example 1 -1), 10 / 90 (embodiment 1-2), 20 / 80 (embodiment 1-3), 30 / 70 (embodiment 1-4) mode regulates the discharge amount of described composition, from hole number 60 Each core-sheath composite fiber is spun into a cooling tank with a spinning head, and then stretched to 4 times in hot water at 9...

Embodiment 1-5~ Embodiment 1-8

[0134] Asahi Kasei Chemical Co., Ltd. manufactured PTT resin crystallized product (intrinsic viscosity 1.0) (PTT resin) as the core component, in the same manner as the above-mentioned Example 1-1 to Example 1-4, to obtain Examples 1-5 where the core / sheath weight ratio is 5 / 95, Examples 1-6 where the core / sheath weight ratio is 10 / 90, and examples where the core / sheath weight ratio is 20 / 80 1-7, and Examples 1-8 in which the core / sheath weight ratio was 30 / 70. Then, with respect to these Examples 1-5 to 1-8, the same steps of weight reduction treatment, dyeing treatment, reduction cleaning treatment, oil agent application, drying, cutting, and combing as the above-mentioned treatments were implemented.

Embodiment 2-1 and Embodiment 2-2

[0144] In addition to carrying out the reduction treatment so that the reduction rate using an alkaline aqueous solution becomes 25%, each treatment was carried out according to Examples 1-2 and Examples 1-6, and the implementation of obtaining black artificial hair with a fineness of 67 dtex was obtained. Example 2-1 and Example 2-2.

[0145] The obtained artificial hair was evaluated for its physical properties, core / sheath area ratio, frizziness, and curling property. These results are shown in Table 3.

[0146] [table 3]

[0147]

[0148] It can be seen from Table 3 that the artificial hair of Example 2-1 and Example 2-2 have the same curly hair setting properties as human hair, but the curly properties are slightly worse.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com