Patents

Literature

37results about How to "Not easy to return" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Absorbent resin particle, and absorber and absorbent article employing the same

An absorbent resin particle, an absorbent body and an absorbent article using the same. The absorbent resin particles comprise a cross-linked polymer (A) formed from a water-soluble vinyl monomer (a1) and / or by hydrolysis ( The vinyl monomer (a2) of a1) and the internal crosslinking agent (b) are essential constituent units, and the absorbent resin particle has a structure in which part or all of (C) is contained in the absorbent resin particle. The present invention can provide absorbent resin particles that can be used in absorbent articles that exhibit high absorption performance (absorption capacity and absorption speed) in any state and are less prone to leakage, and absorbent bodies and absorbent articles using the same.

Owner:SAN DIA POLYMERS LTD

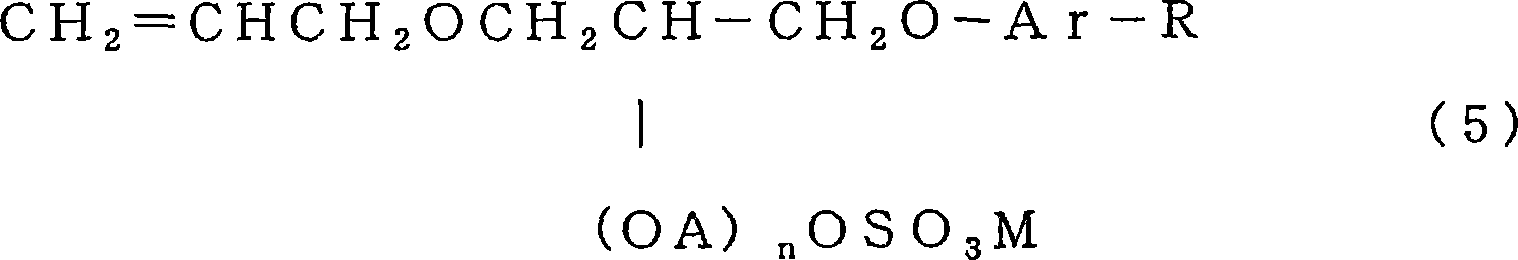

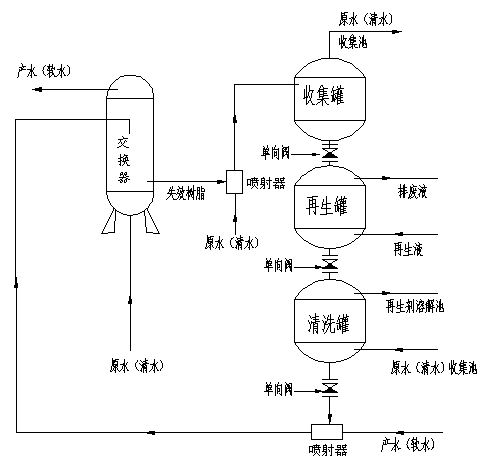

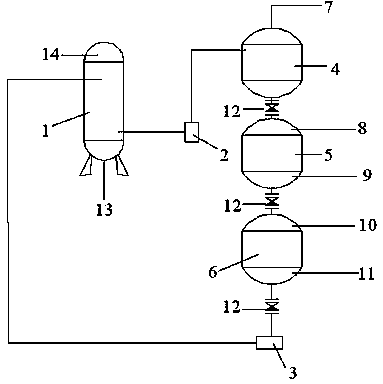

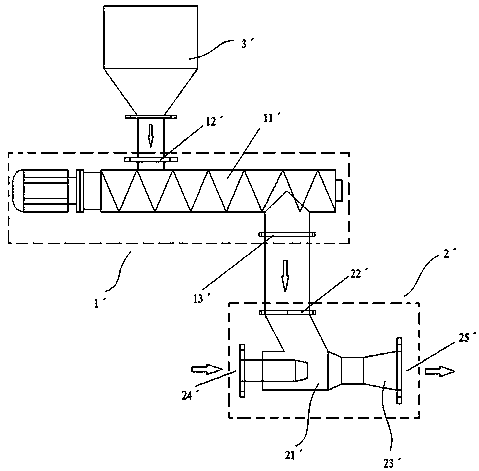

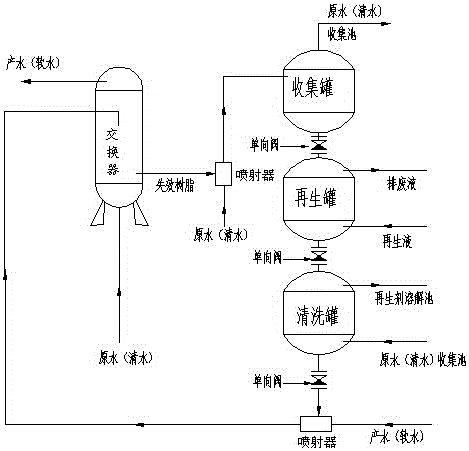

Extracorporeal upflow regeneration process for ion exchange resin

ActiveCN104003478ADoes not affect productionRealize continuous productionWater/sewage treatment by ion-exchangeIon exchange beds cleaning/rinsingWater flowIon exchange

The invention provides an extracorporeal upflow regeneration process for ion exchange resin. The process includes the following steps that firstly, soft water is produced, and meanwhile exhausted resin is continuously discharged from the lower portion of an ion exchanger; secondly, the exhausted resin is conveyed to a gathering tank through injection, conveying fluid is drained from the upper portion of the gathering tank, and the exhausted resin is discharged from the bottom of the gathering tank and enters a regeneration tank; thirdly, regeneration fluid flows into the lower portion of the regeneration tank, upflow regeneration is conducted on the exhausted resin, and regenerated resin is discharged from the bottom of the regeneration tank and enters a cleaning tank; fourthly, water flows into the lower portion of the cleaning tank, the regeneration fluid left on the regenerated resin is reversely cleaned away, and the cleaned regenerated resin is discharged from the bottom of the cleaning tank and is conveyed back to the ion exchanger through injection. According to the process, the soft water can be continuously produced, energy consumption is reduced, and the equipment utilization rate is increased.

Owner:CHENGDU GRACE FIBER +1

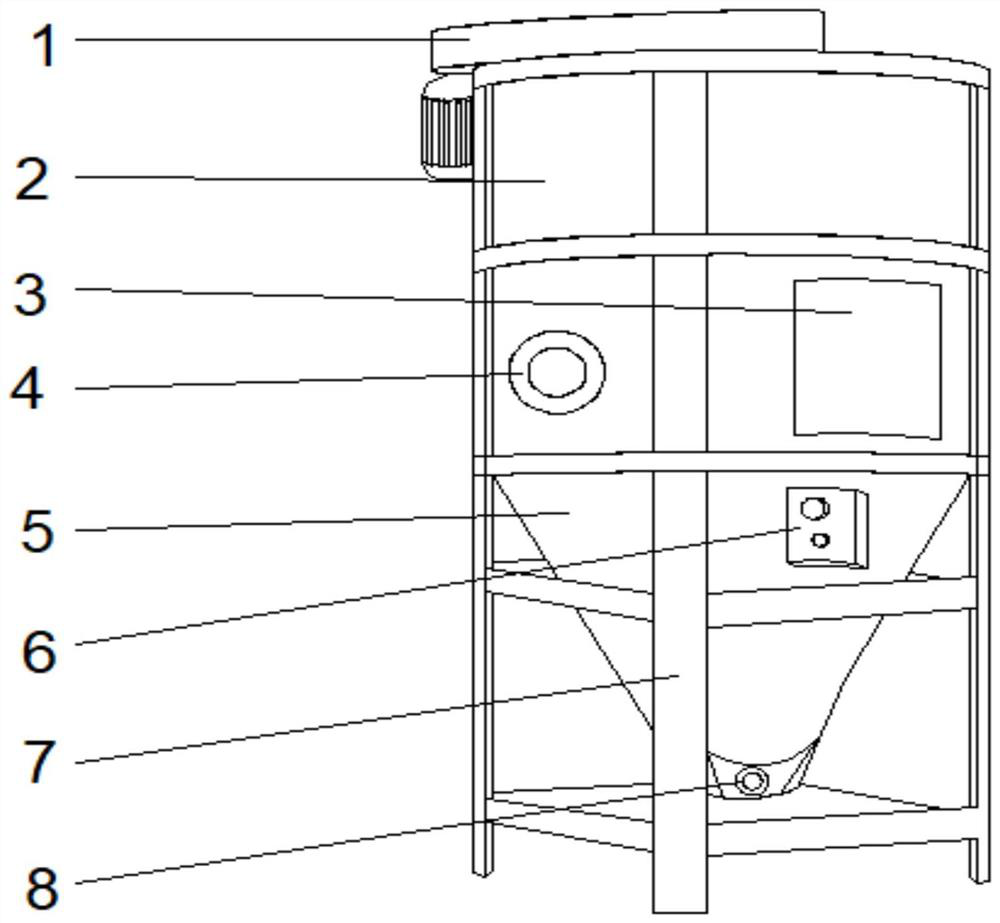

Textile dye mixing device

PendingCN112473515AImprove collection efficiencyAvoid cloggingTransportation and packagingMixer accessoriesFixed frameTextile technology

The invention discloses a textile dye mixing device, and the device comprises a fixed frame and is characterized in that stirring devices are fixedly connected to the inner walls of the two sides of the fixed frame, stirrers are arranged at the tops of the stirring devices, feeding ports are formed in the middles of the left sides of the front faces of the stirring devices, and observation windowsare formed in the right sides of the front faces of the stirring devices; a collecting device is arranged on the inner walls of the two sides of the fixed frame and located at the bottom of the stirring device, a controller is fixedly connected to the right side of the top of the front face of the collecting device, and a discharging port is formed in the bottom of the collecting device. The invention relates to the technical field of textiles. According to the textile dye mixing device, the cutting mechanism in the stirring device rotates along with the stirring rod, the stirring device makes contact with dye before the dye is smashed and stirred, some blocky dyes are convenient to smash and mix, the quality of textile finished products is not affected, the stirring process and the stirring degree are convenient to observe, and therefore adjustment is conducted in time.

Owner:韩文杰

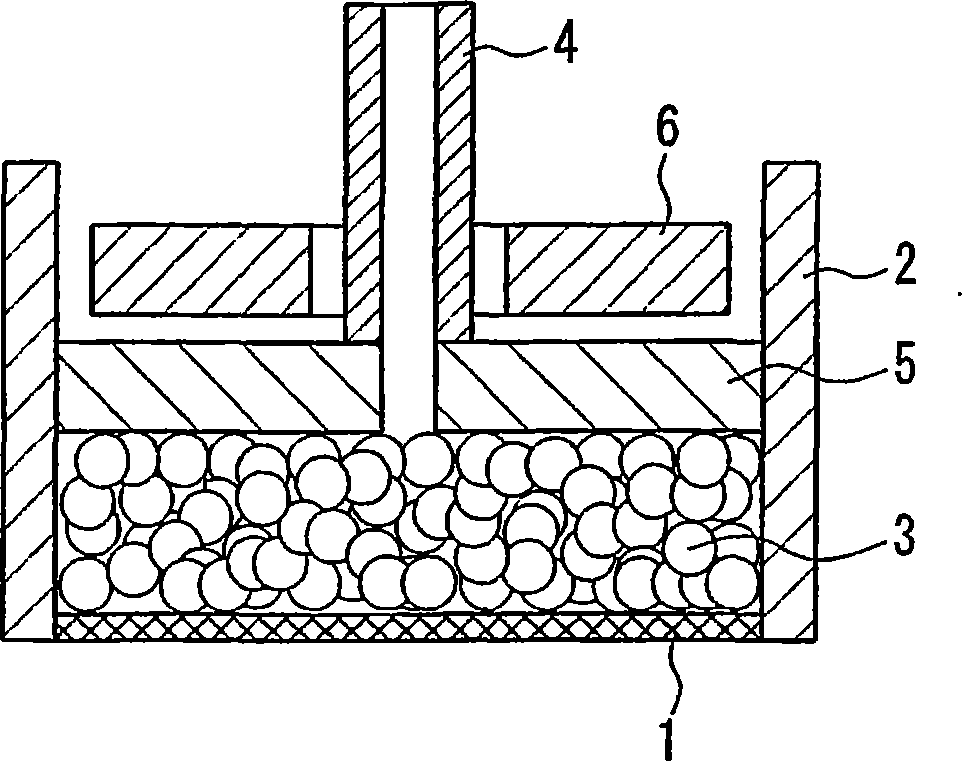

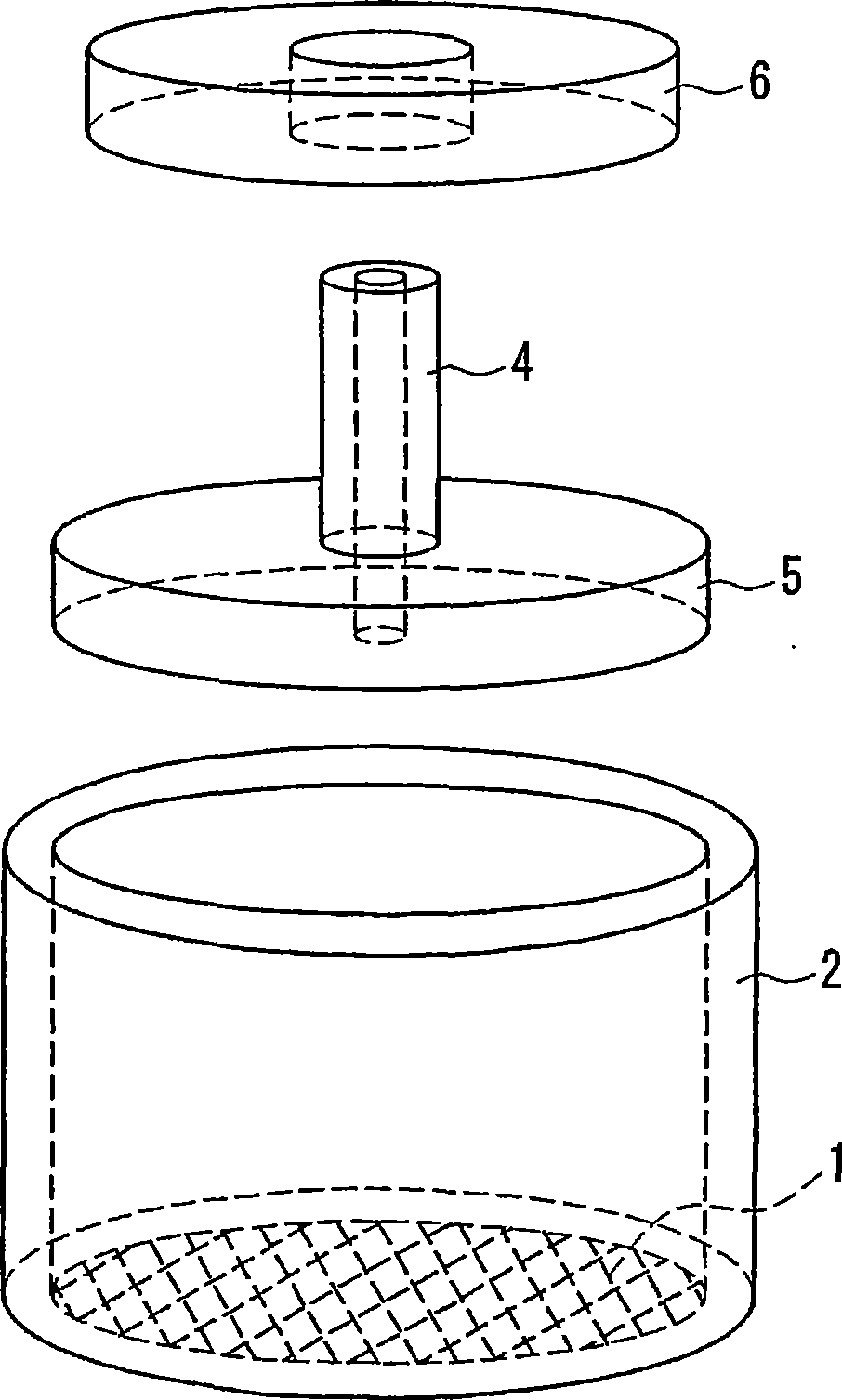

Production method of bentonite and calcium chloride compound drying agent

InactiveCN108031434AGood moisture absorptionNot easy to returnOther chemical processesDispersed particle separationChemistryDrying Agents

The invention provides a production method of a bentonite and calcium chloride compound drying agent. The bentonite compound drying agent finished product is formed by the processes of processing bentonite powder, adding calcium chloride for compounding, flaking the obtained compound to obtain compound drying agent pieces, and drying. The compound drying agent is prepared by taking the bentonite as a raw material and adding the calcium chloride for compounding; the compound drying agent has the advantages of having a good moisture absorption effect, enabling moisture not easily to return, andbeing low in price, safe and non-toxic, thus being suitable for being used as a drying agent.

Owner:建昌县建元澎润土有限责任公司

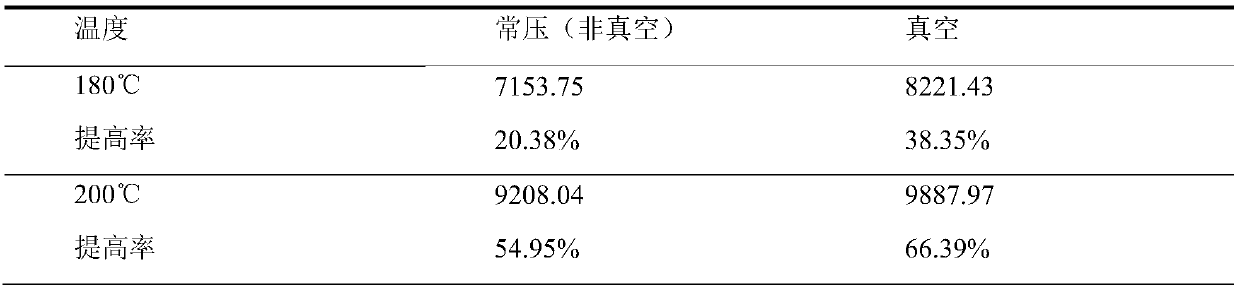

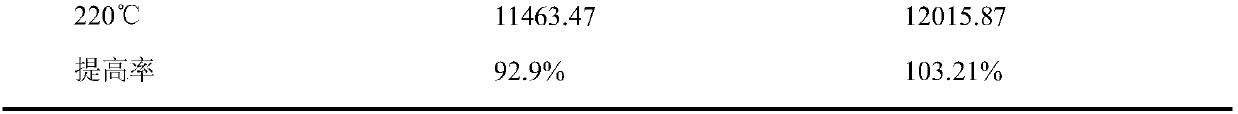

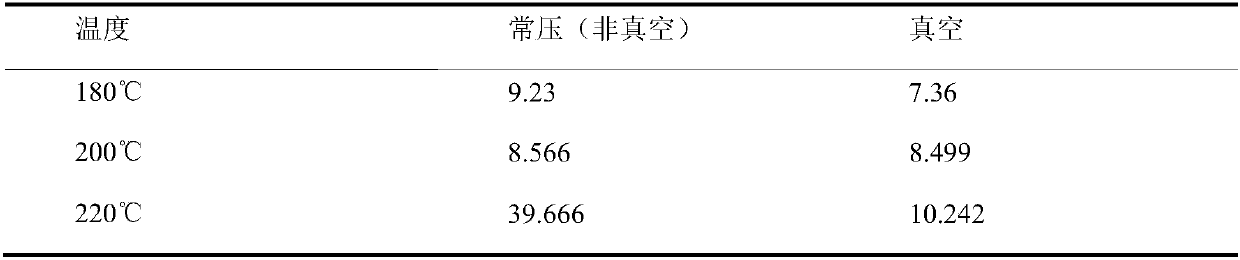

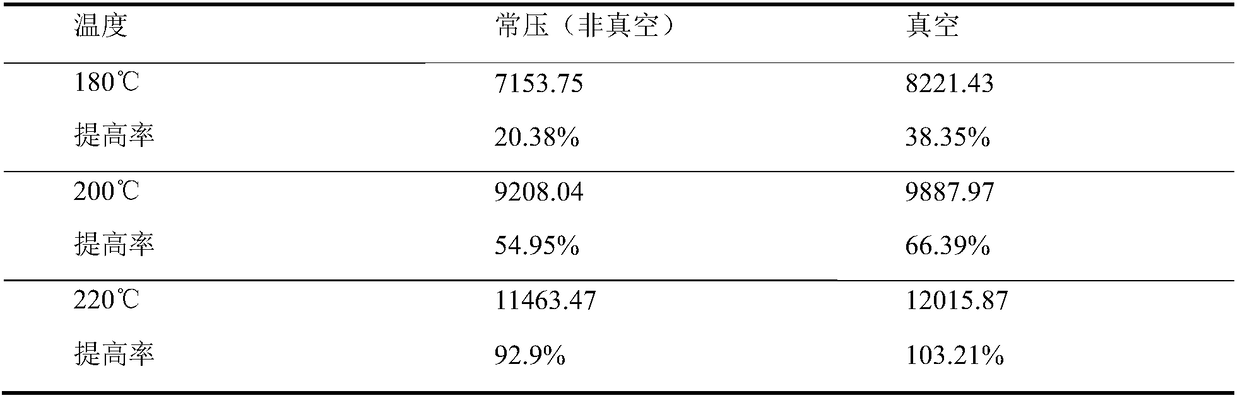

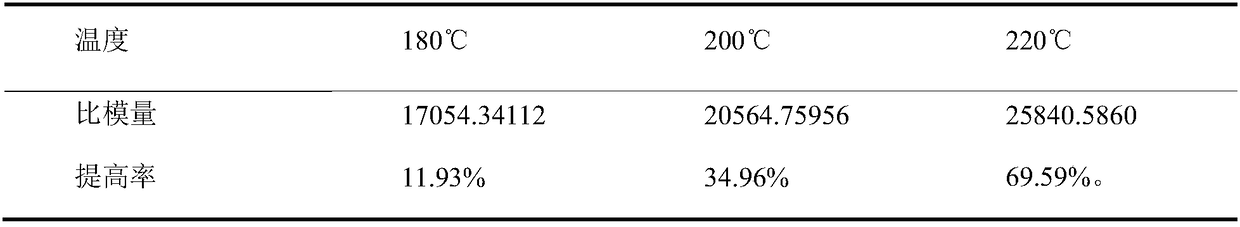

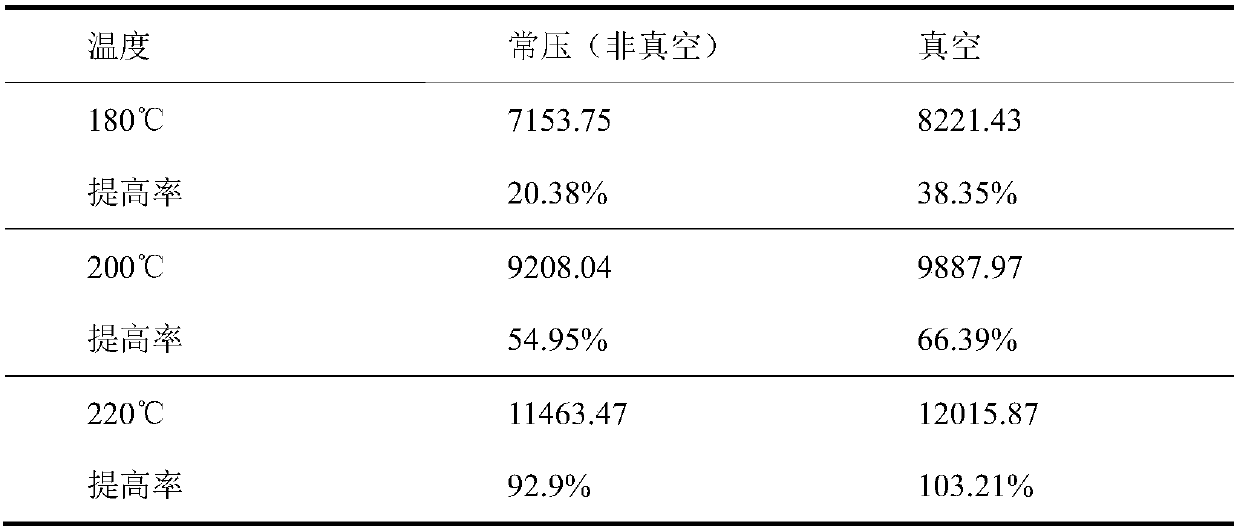

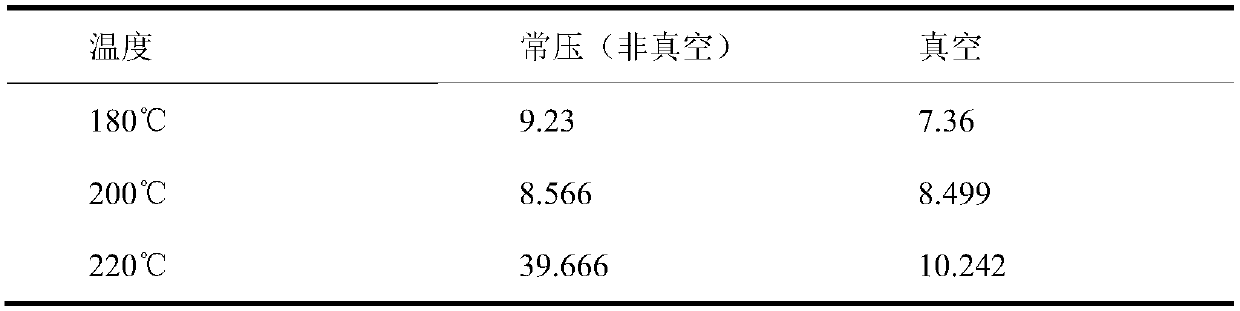

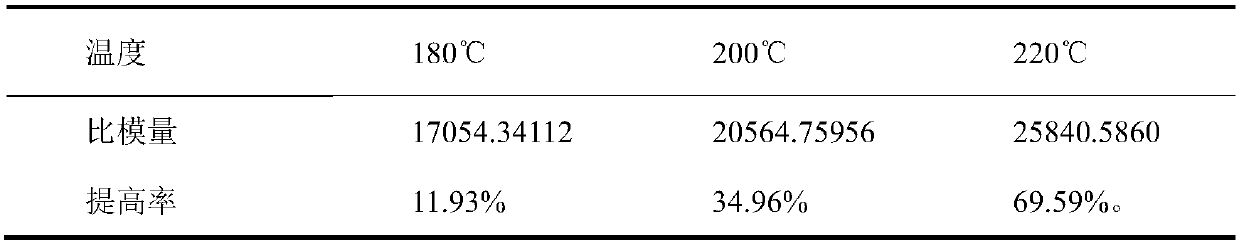

Method for compressing and compacting wood materials in vacuum

ActiveCN109591122ASolve easy discolorationFix stability issuesWood veneer joiningColor changesUltimate tensile strength

The invention discloses a method for compressing and compacting wood materials in vacuum, and belongs to the field of wood material production and preparation. According to the method, the wood materials undergo hot-pressing setting treatment under the vacuum condition, the treated wood materials are large in specific modulus, so that the technical problems that in the case of an existing wood material compression and compaction technology, the hot-pressing setting time is long, the manufacturing efficiency is low, the color change and the size are not stable are solved, the compression and compaction manufacturing of the wood materials is performed under the vacuum condition, so that the gluing strength of the wood gluing materials is also improved.

Owner:NANJING FORESTRY UNIV

Method for compressing and compacting wood materials

ActiveCN108177209ASolve easy discolorationFix stability issuesWood veneer joiningColor changesSpecific modulus

The invention discloses a method for compressing and compacting wood materials, and belongs to the field of wood material production and preparation. According to the method for compressing and compacting the wood materials, the wood materials are subjected to hot-pressing and setting treatment under the vacuum condition, and the processed wood materials are large in specific modulus, and the technical problems that, in an existing wood material compressing and compacting technology, the hot-pressing and setting time of is long, manufacturing efficiency is low, the color changes, and the sizeis not stable are solved; and the wood materials are subjected to compressing and compacting manufacture under the vacuum condition, so that bonding strength of the wood materials laminated with glueis also improved.

Owner:NANJING FORESTRY UNIV

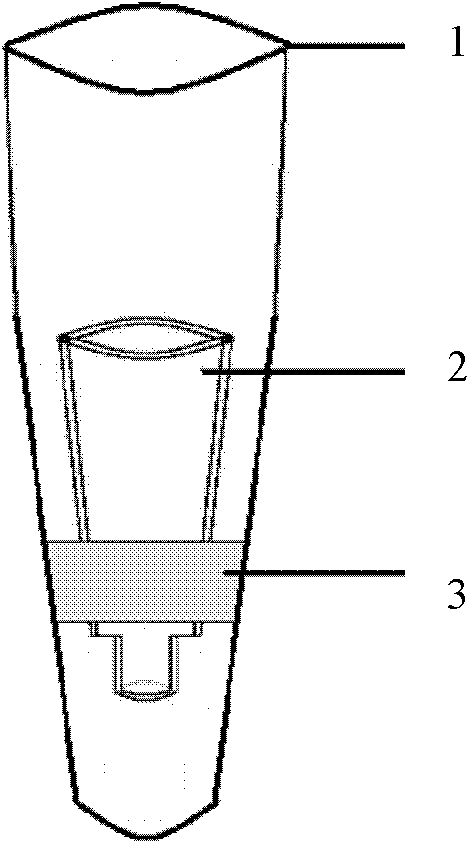

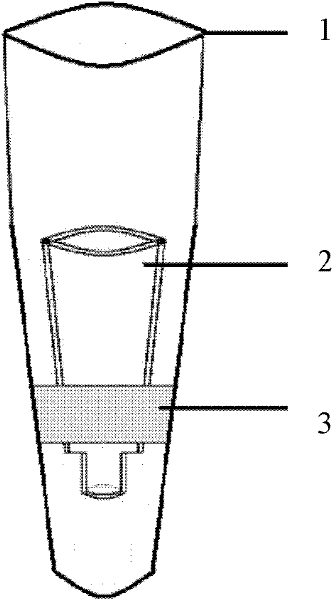

Method and device for separating sperms

InactiveCN101831383AEasy accessNot easy to returnBioreactor/fermenter combinationsBiological substance pretreatmentsRubber ringLow speed

The invention discloses simple and high-efficient method and device for separating sperms. The device consists of an Eppendorff centrifugal tube, a separating tube and a rubber ring. The method comprises the steps of: reasonably controlling the level height of culture solution; and culturing in a 5 percent CO2 culture container at 37 DEG C for 15minutes for separating the sperms. The concentration of the sperms can be adjusted by adopting a low-speed centrifugal method; about 95 percent of obtained sperms have athletic ability; and the collected solution generally has no blood cells. The invention is suitable for an in vitro capacitation experiment.

Owner:CENT SOUTH UNIV

External regeneration reverse-flow ion exchange system and application method thereof

ActiveCN104003477AIncrease profitSave time and energyIon-exchanger regenerationWater/sewage treatment by ion-exchangePhysicsIon exchange

The invention provides an external regeneration reverse-flow ion exchange system and an application method of the external regeneration reverse-flow ion exchange system. The external regeneration reverse-flow ion exchange system comprises an ion exchanger, an ejector, a collecting tank, a regeneration tank and a cleaning tank, wherein the ion exchanger, the ejector, the collecting tank, the regeneration tank and the cleaning tank are connected in sequence, the bottom of the collecting tank is connected with the top of the regeneration tank, the bottom of the regeneration tank is connected with the top of the cleaning tank, the bottom of the cleaning tank is connected back to the ion exchanger, the ejector is arranged between the cleaning tank and the ion exchanger, a water outlet is formed in the collecting tank, a liquid inlet is formed in the lower portion of the regeneration tank, a liquid discharge outlet is formed in the upper portion of the regeneration tank, a water inlet is formed in the lower portion of the cleaning tank, and a water discharging outlet is formed in the upper portion of the cleaning tank. According to the application method of the external regeneration reverse-flow ion exchange system, ion exchange resin out of work is processed through reverse flow regeneration outside the exchanger and then returns to the exchanger, soft water can be continuously produced, energy consumption is reduced, and the equipment utilization rate is increased.

Owner:CHENGDU GRACE FIBER +1

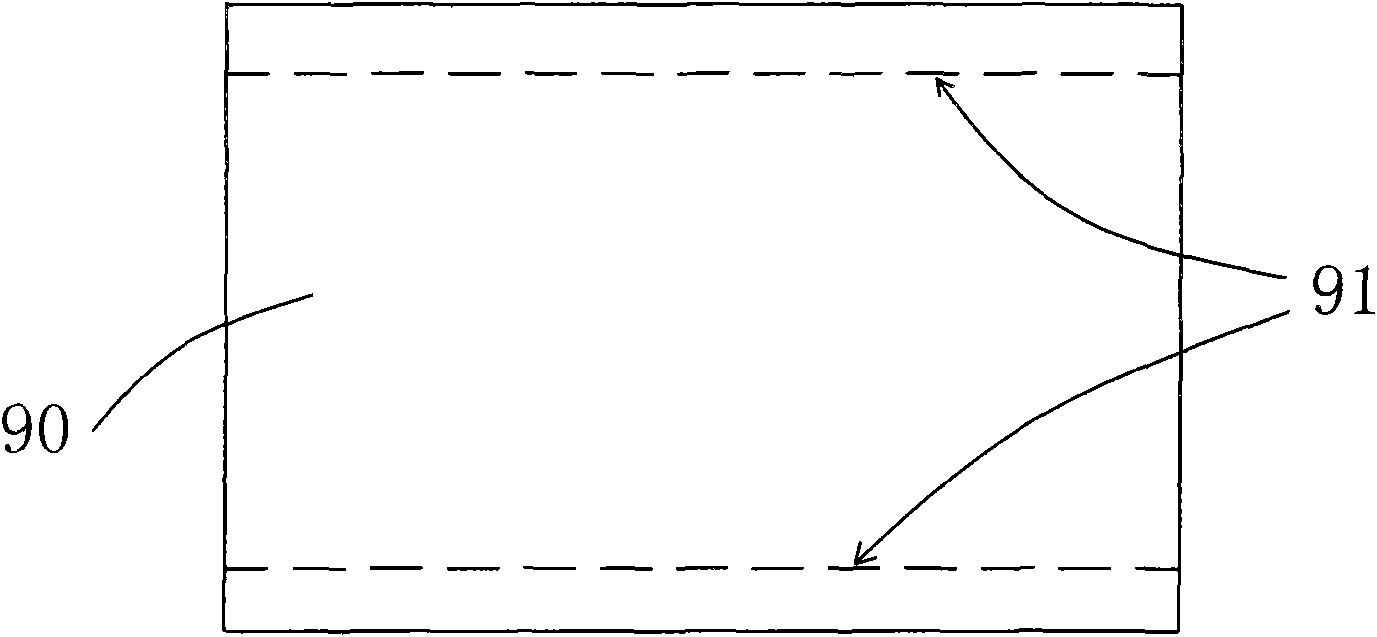

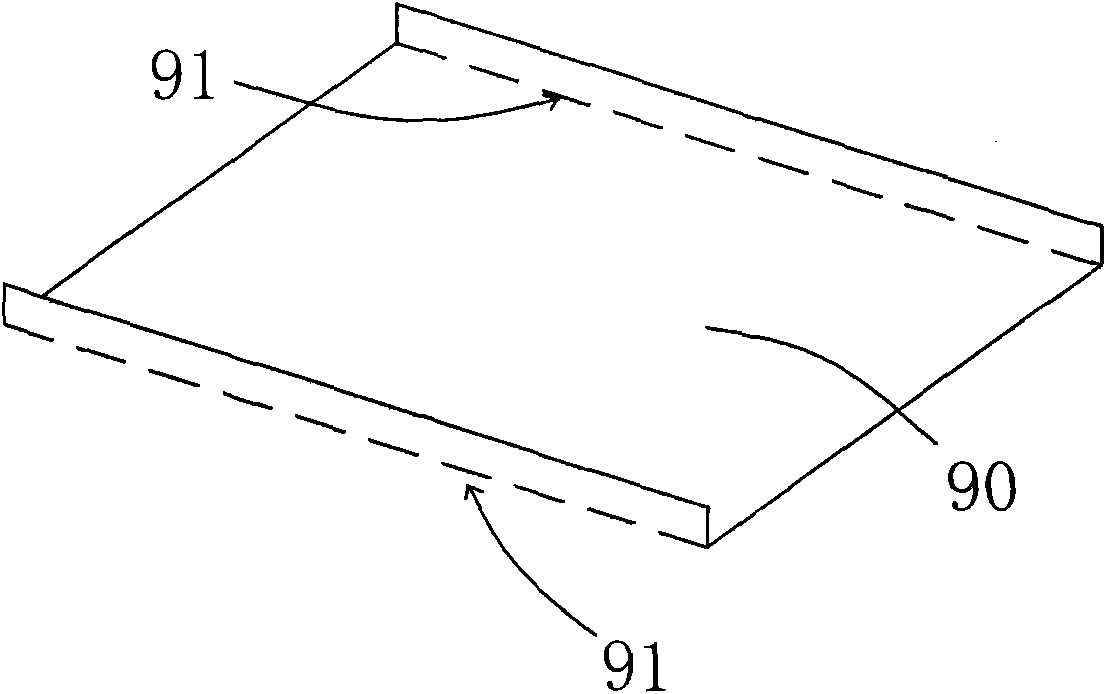

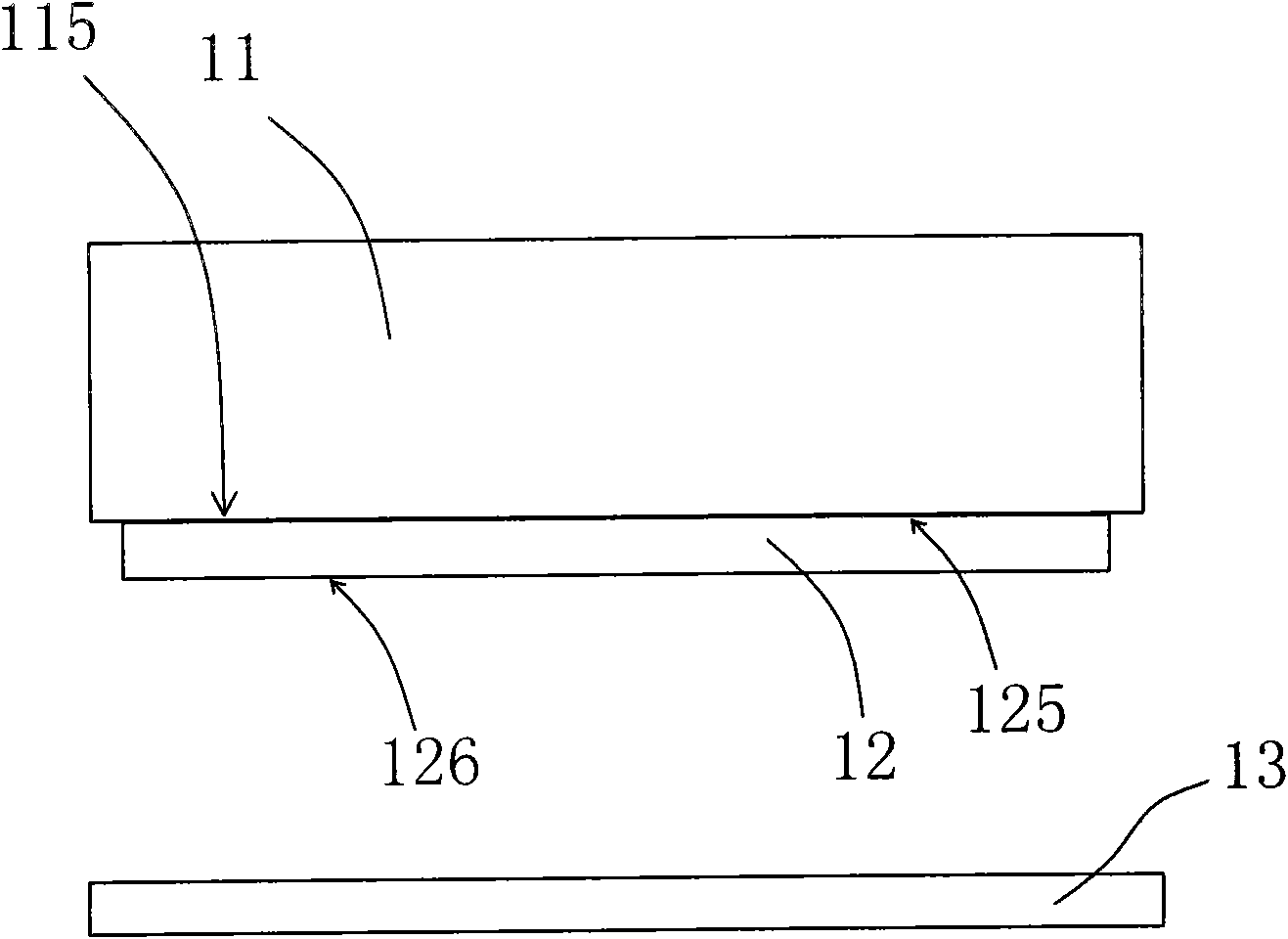

Cutting and bending device and membrane cutting and bending method

The invention relates to a cutting and bending device and a membrane cutting and bending method. The cutting and bending device comprises a positioning table, a cutting die, a cutter, a fold fin, a heater and a supporting table, wherein the positioning table has a positioning surface; the cutting die has a first surface and a second surface which are opposite, and the first surface is positioned on the positing surface; the cutter and the fold fin are vertically arranged on the second surface of the cutting die; the heater is arranged in the cutting die and heats the fold fin; and the supporting table is arranged in a way of corresponding to the second surface of the cutting die.

Owner:BENQ MATERIALS +1

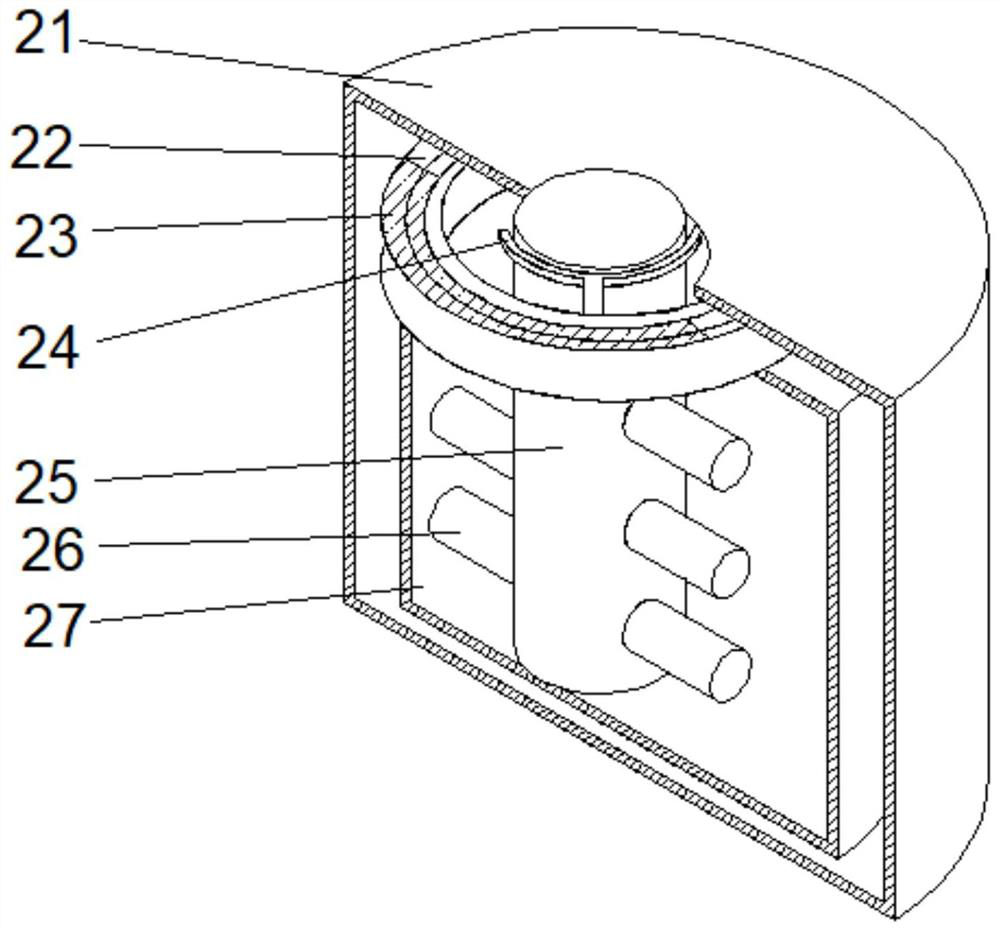

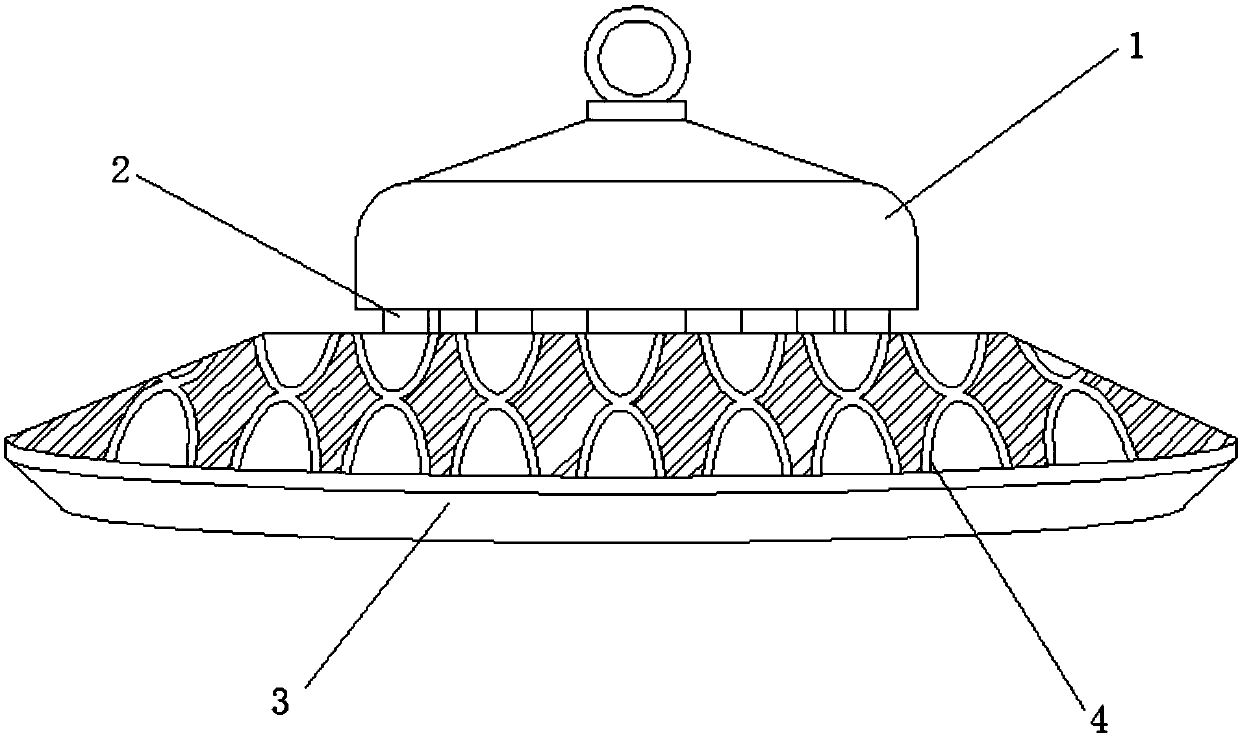

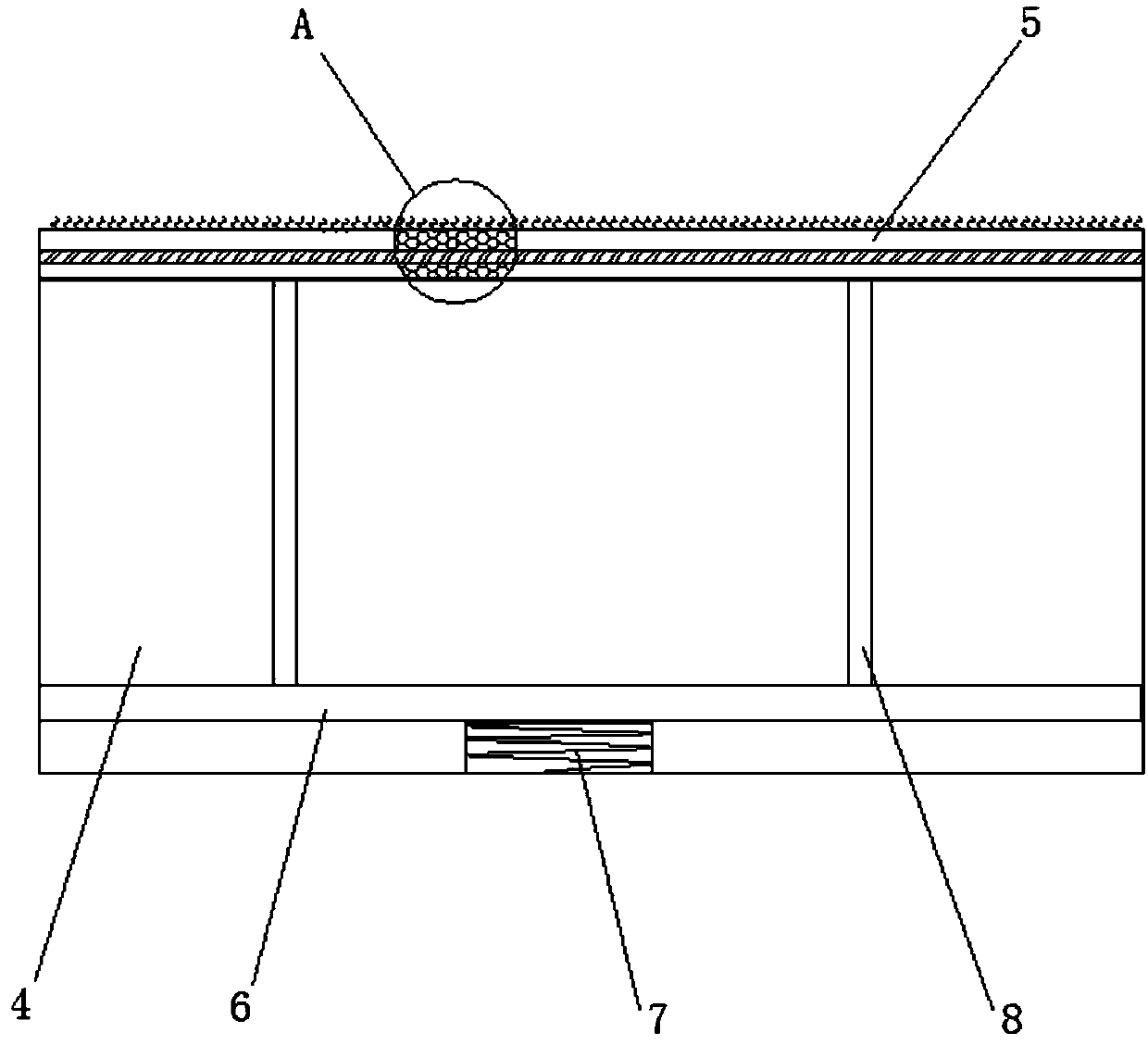

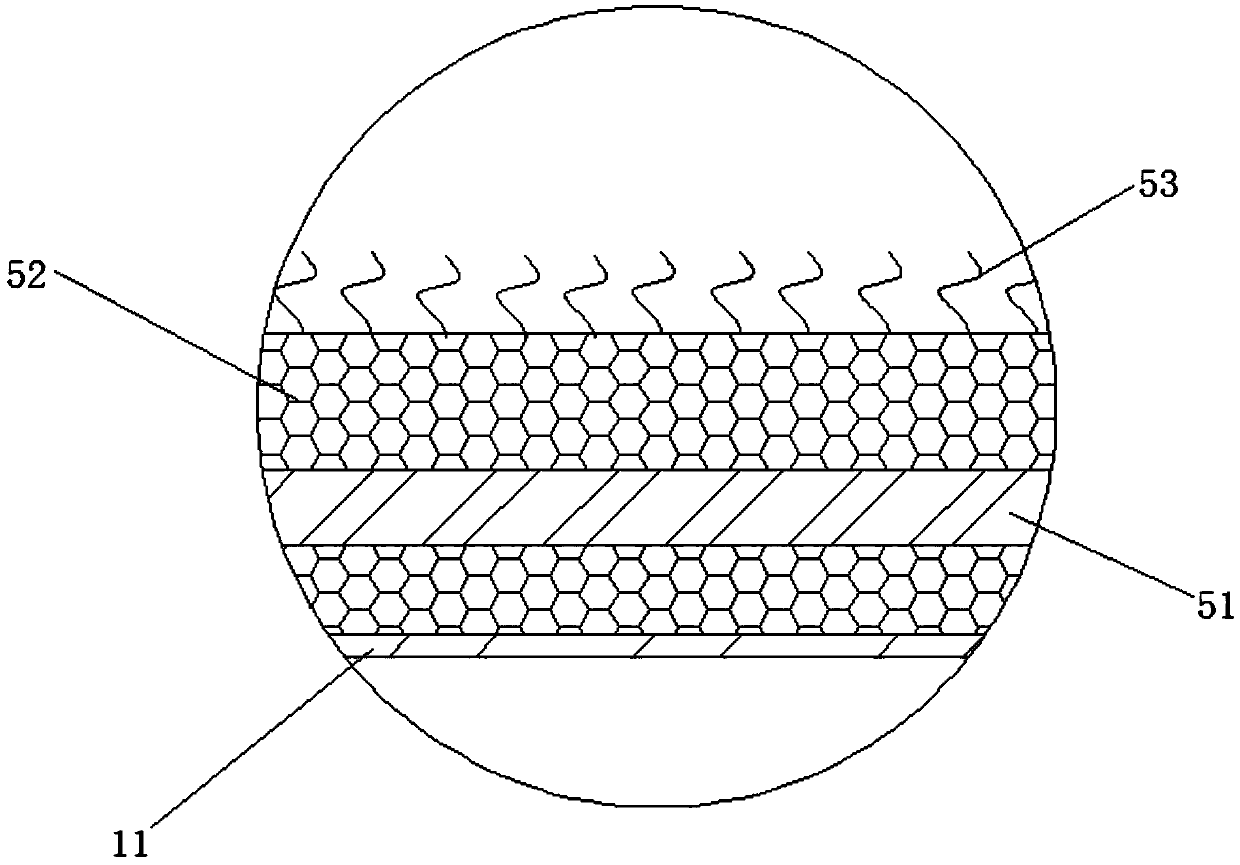

LED factory lamp with air channel optimized through fin group applied to normal temperature state

PendingCN109556032AImprove cooling effectGuaranteed cleanlinessLighting heating/cooling arrangementsCleaning using toolsCooling effectEngineering

The invention discloses an LED factory lamp with an air channel optimized through a fin group applied to the normal temperature state, and belongs to the field of LED factory lamps. The LED factory lamp with the air channel optimized through the fin group applied to the normal temperature state comprises a lamp holder connected to the lower end of a mounting base through a connecting post, a lampbead is mounted inside the lamp holder, the air channel is arranged at the upper end of the lamp holder, the air channel comprises cooling fins, temperature variation type dust collecting mechanisms are arranged on two sides of the cooling fins, and each temperature variation type dust collecting mechanism comprises a dust collecting net, a specially-shaped dust collecting movable plate and a temperature variation rod. According to the technical scheme, the surface of the lamp holder is arranged to be the fin group, so that the cooling air channel of the lamp body is optimized, in addition, the temperature variation type dust collecting mechanisms are arranged on the surfaces of the cooling fins in the fin group from, the temperature variation type dust collecting mechanisms can be used for carrying out automatic dust colleting on the surfaces of the cooling fins during the work process of the LED factory lamp, so that the cleanness of the surfaces of the cooling fins is maintained, therefore, the good cooling effect of the cooling fins is guaranteed, and further, the service life of the LED factory lamp is prolonged.

Owner:江苏新西贝机电有限公司

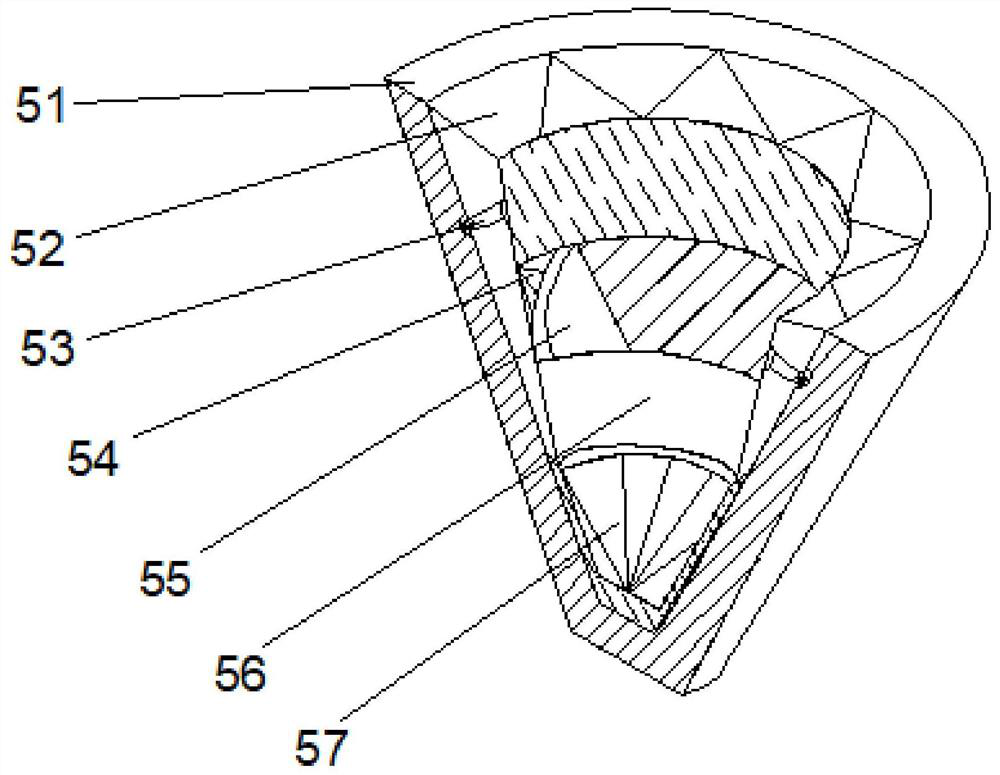

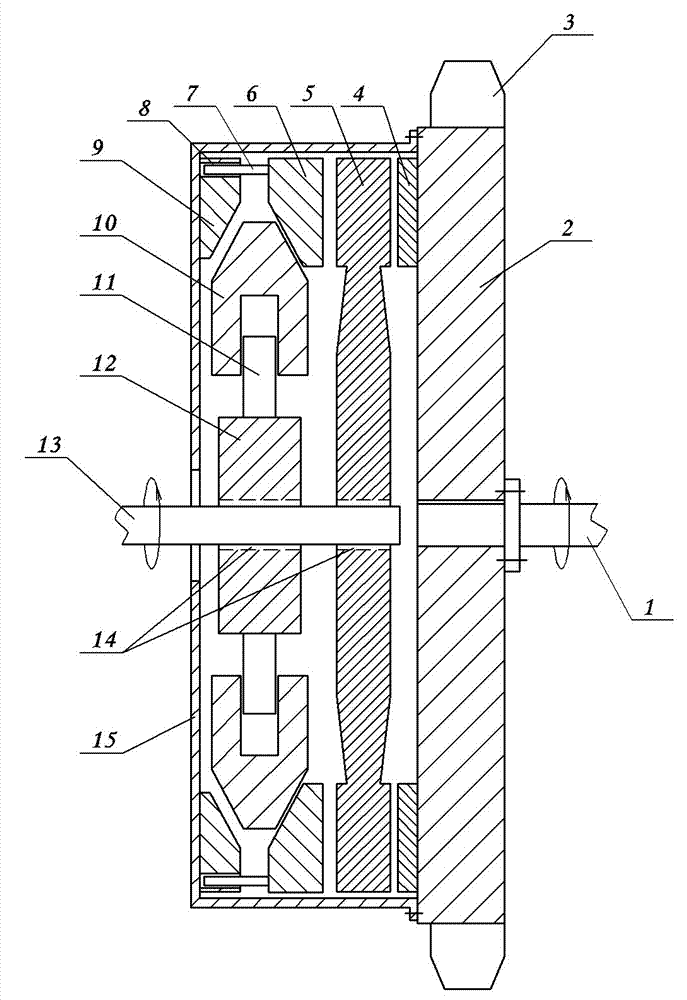

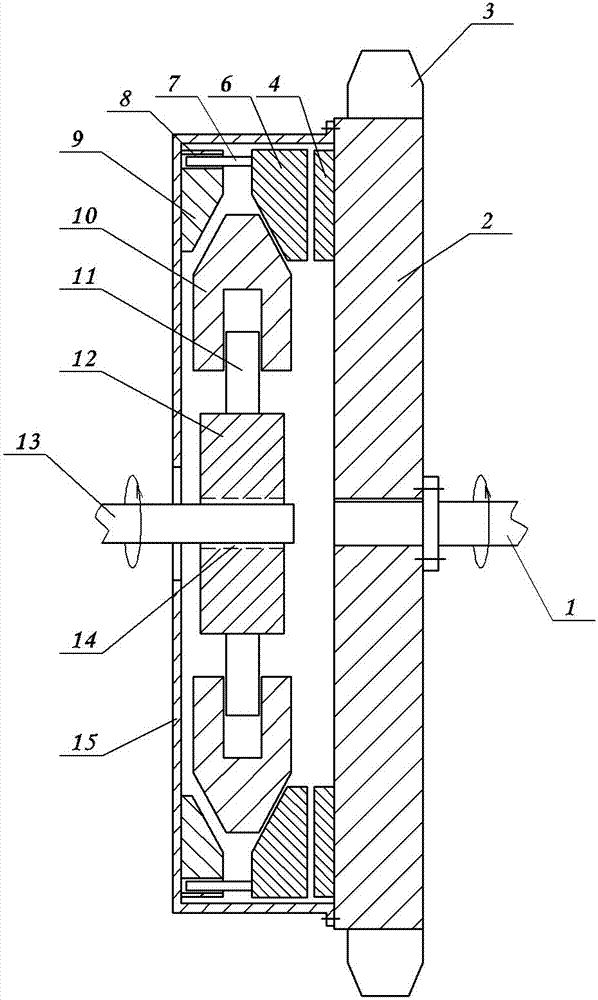

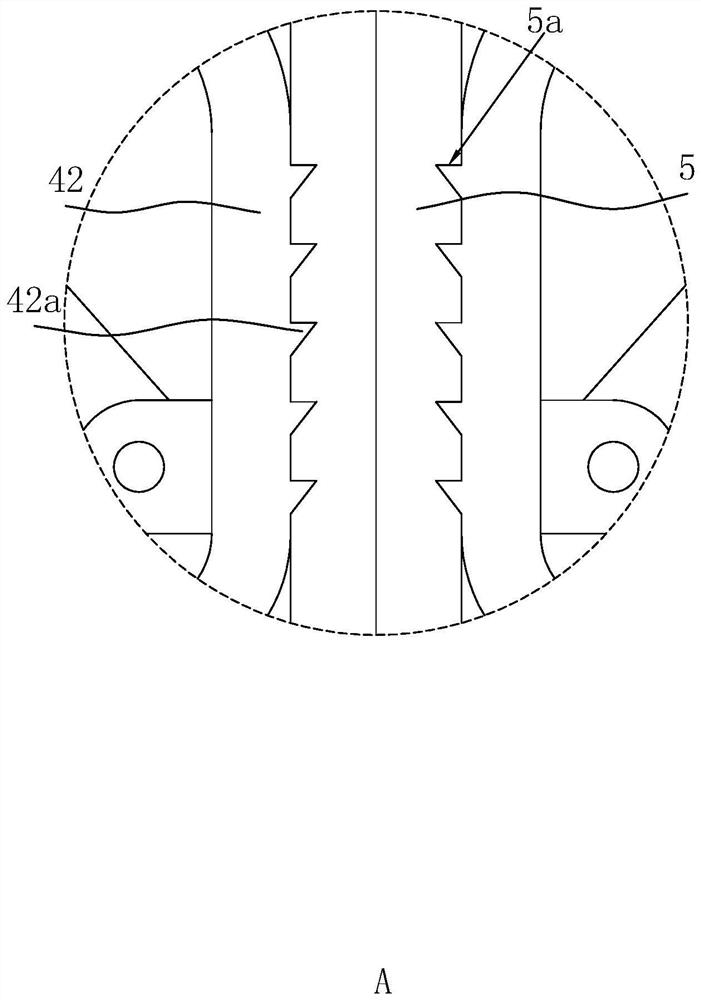

Centrifugal pressure plate automatic clutch

InactiveCN103089850AImprove performanceHigh friction and stabilityAutomatic clutchesCentrifugationAxial pressure

The invention discloses a centrifugal pressure plate automatic clutch which comprises a pressure plate, a driving part, a centrifugation body and a driven part. A fixed block and a sliding block are arranged in the pressure plate. A cone-shaped opening is formed in the inner edges of the fixed block and the sliding block. The outer edge of the centrifugation body is arranged to be a cone-shaped protrusion. The cone-shaped protrusion and the cone-shaped opening can be arranged together in a matching mode. One side, close to the driven part, of the sliding block is matched with the driven part in a mode of friction through a friction disc or is directly matched with the driven part in the mode of friction. According to the centrifugal pressure plate automatic clutch, radial pressure of the centrifugation body is converted to axial pressure, pressure of a friction surface is enabled not to be changed easily, load with large torque can be transmitted, influence of speed changing is almost avoided, and the problem of friction heating before reaching rated rotating speed is almost not considered. The centrifugal pressure plate automatic clutch is reasonable in structure, and good in using effect, and can be popularized and implemented conveniently.

Owner:杨勇

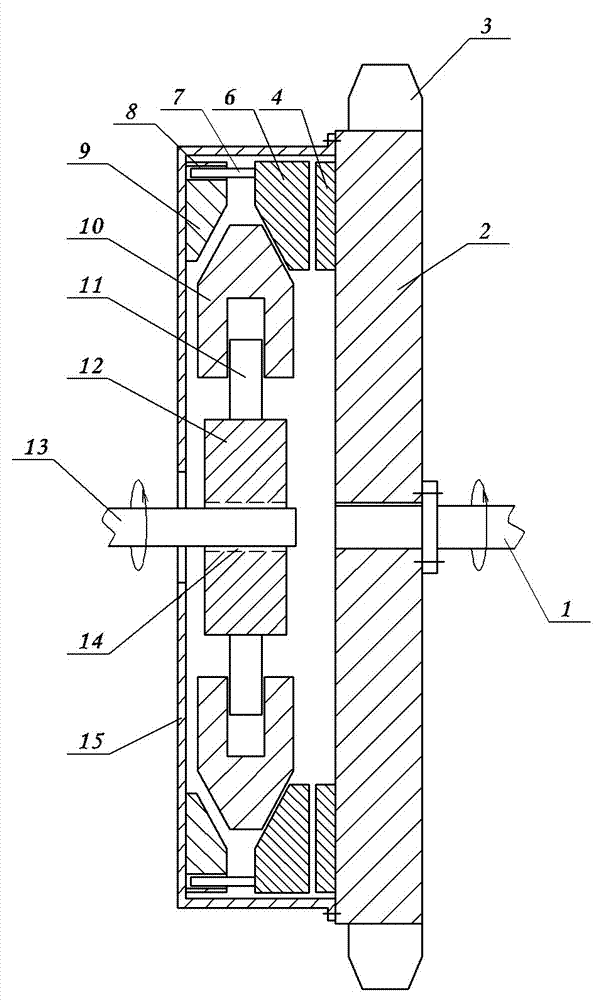

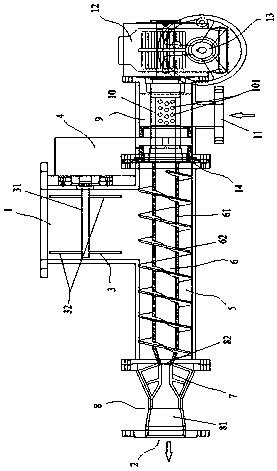

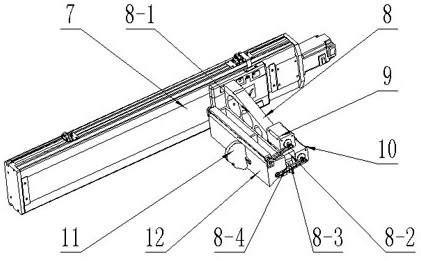

Air conveying type spiral feeding system

InactiveCN108622624AReduce idling and no dischargeReduce the situationMechanical conveyorsSpiral bladeBatch operation

An air conveying type spiral feeding system includes a material inlet, a material outlet, an anti-bridging device, a transmission case, a mixing chamber, a screw conveyor, reamers, an ejector, an inlet air chamber, a ventilation duct, an air inlet, a speed reducer and a motor. The inlet air chamber, the mixing chamber and the ejector are sealingly separated; the upper end of the material inlet isprovided with the anti-bridging device; the material inlet communicates with the mixing chamber; the screw conveyor is disposed inside the mixing chamber; the screw conveyor includes a hollow spiral pipe and spiral blades winding the outer wall of the spiral pipe; the reamers are disposed at a connecting position between a throat port of the ejector and the spiral pipe; the ventilation duct is disposed inside the air inlet chamber; the pipe wall of the ventilation duct is provided with circular holes; the spiral pipe is coaxially connected to the pipe port of the ventilation duct; the sealingjoint is surrounded with a gear; the gear engages with chain inside the transmission case to drive the anti-bridging device to rotate; and the ventilation duct is rotatably connected to an output shaft of the motor through the speed reducer. The invention provides an integrated air conveying type spiral feeding system having the characteristics of low power consumption, smooth batching operation and high efficiency.

Owner:上海洋野流体设备有限公司

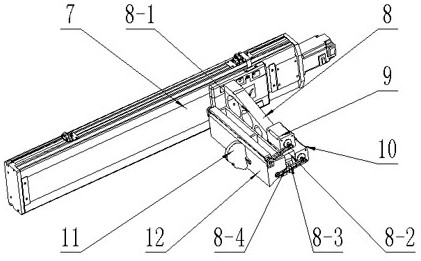

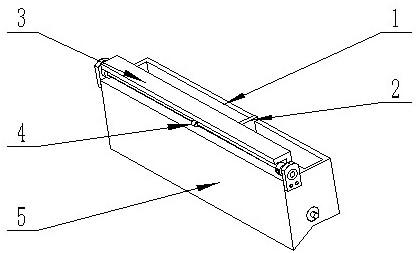

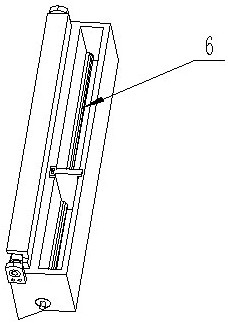

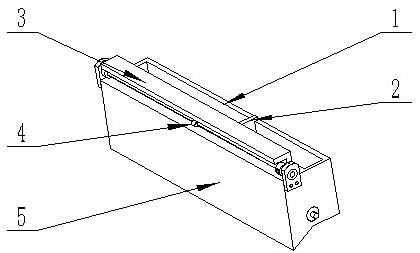

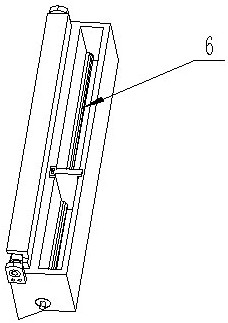

Powder spreading device for 3D printer

ActiveCN113118471AReduce pollutionReduce recycling workloadAdditive manufacturing apparatusLinear motionComputer printing

The invention discloses a powder spreading device for a 3D printer. The method comprises the steps that a powder falling module is mounted on one side of a linear motion module and comprises a powder spreading bin, a powder spreading roller, a switch control panel, a cam control shaft and an isolation baffle; a vertical plate is arranged in the powder spreading bin, and the lower end of the vertical plate is separated from a bottom plate of the powder spreading bin; the powder spreading roller is arranged between the lower end of the vertical plate and the bottom plate of the powder spreading bin and divides the powder spreading bin into a powder storage bin and a powder falling bin together with the vertical plate, the two ends of the powder spreading roller are movably mounted in the powder spreading bin, and powder can be conveyed from the powder storage bin to the powder falling bin through rotation of the powder spreading roller; the switch control panel is movably mounted in the powder falling bin and is provided with a boss; a cam is arranged on the cam control shaft and is tangent to the boss, and the two ends of the cam control shaft are movably mounted in the powder falling bin; the isolation baffle is arranged in the powder storage bin and divides the powder storage bin into an empty bin and a powder adding bin. Reasonable powder feeding can be carried out according to the number of parts, the powder cleaning workload is reduced, the iteration speed of product research and development is increased, and the research and development efficiency is improved.

Owner:ZHONGBEI UNIV

Ornamental glass and manufacturing method thereof

PendingCN106956544ASoft visionNo glareDecorative surface effectsSpecial ornamental structuresLacquerEtching

The invention discloses ornamental glass. The ornamental glass comprises toughened glass used as a bottom plate; the toughened glass comprises a pattern zone; the pattern zone comprises a sand carving zone, a chemical liquid etching zone, waistlines, a bottom line and an antique process zone; a diamond powder layer is arranged on the toughened glass; an environment-friendly paint layer is arranged on the diamond powder layer; and an art glass patch is attached to the environment-friendly paint layer. A manufacturing method of the ornamental glass comprises the steps as follows: (1) a pattern is carved in the bottom plate; (2) sand is sprayed for carving; (3) chemical liquid etching is performed; (4) computer turning carving is performed; (5) gummed paper is removed; (6) art painting is performed; (7) diamond powder is spread; (8) over-printing varnish is sprayed; (9) art attaching is performed. The glass has the touchable 3D image, is concave and convex, has the texture effect and is not prone to sound return, light return, image return, mildewing, scratching and fog formation, multiple process means cooperate, relief art glass patches made of various materials can be adopted, the style is different from the rest, the glass is attractive in appearance, durable, safe and reliable, the diffusion and reflection visual sense is soft and not dazzling.

Owner:黄利安

A method for compressing and densifying wood materials

ActiveCN108177209BSolve easy discolorationFix stability issuesWood veneer joiningUltimate tensile strengthMaterials science

The invention discloses a method for compressing and densifying wood materials, which belongs to the field of wood material production and preparation. In the present invention, the wood is subjected to hot-pressing and setting treatment under vacuum conditions, and the treated wood has a large specific modulus, which solves the problems of long hot-pressing and setting time, low manufacturing efficiency, discoloration and dimensional instability in the existing wood compression and compaction technology. Technical problem; the compression and densification of wood materials under vacuum conditions also improves the bonding strength of wood glued materials.

Owner:NANJING FORESTRY UNIV

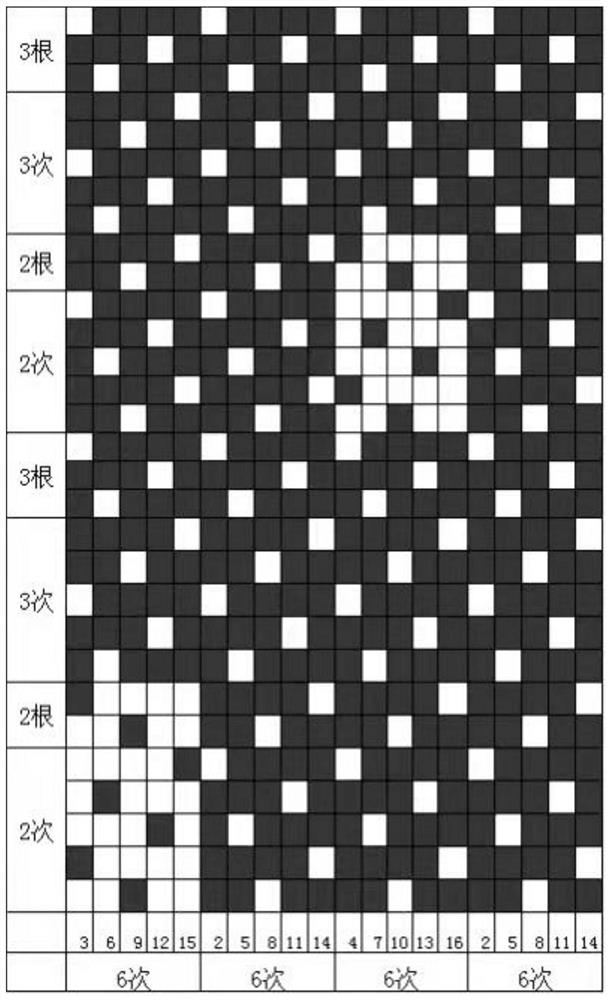

Combed cotton and tencel fiber blended 60S babysbreath figured cloth and weaving process thereof

The invention discloses combed cotton and tencel fiber blended 60S babysbreath figured cloth and a weaving process thereof. The combed cotton and tencel fiber blended 60S babysbreath figured cloth comprises fabric, the fabric is formed by blending and weaving combed cotton and tencel fibers, warp yarn of the fabric is combed cotton, and weft yarn of the fabric is tencel. The weaving process comprises the following steps that S1, warping is carried out, combed cotton warp yarns are led out from original cheese by adopting a batch warping machine to uniformly form a yarn sheet; S2, slashing is carried out, specifically, a slashing machine is adopted to perform single-dipping and double-pressing sizing on yarn sheets; S3, denting is carried out; and S4, weaving is carried out. According to the combed cotton and tencel fiber blended 60S babysbreath figured cloth and the weaving process thereof, the 'early opening' process design is adopted, so that the weft yarns are easy to tighten and not prone to returning; during beating-up, the tension difference of upper and lower layers of warp yarns is large, so that the warp yarns can be uniformly arranged, reed mark defects can be eliminated, the warp density of the prepared fabric is large, the delayed warp feeding time is adopted, and the skip defect on the weft yarn inlet side can be reduced.

Owner:JIHUA 3542 TEXTILE CO LTD

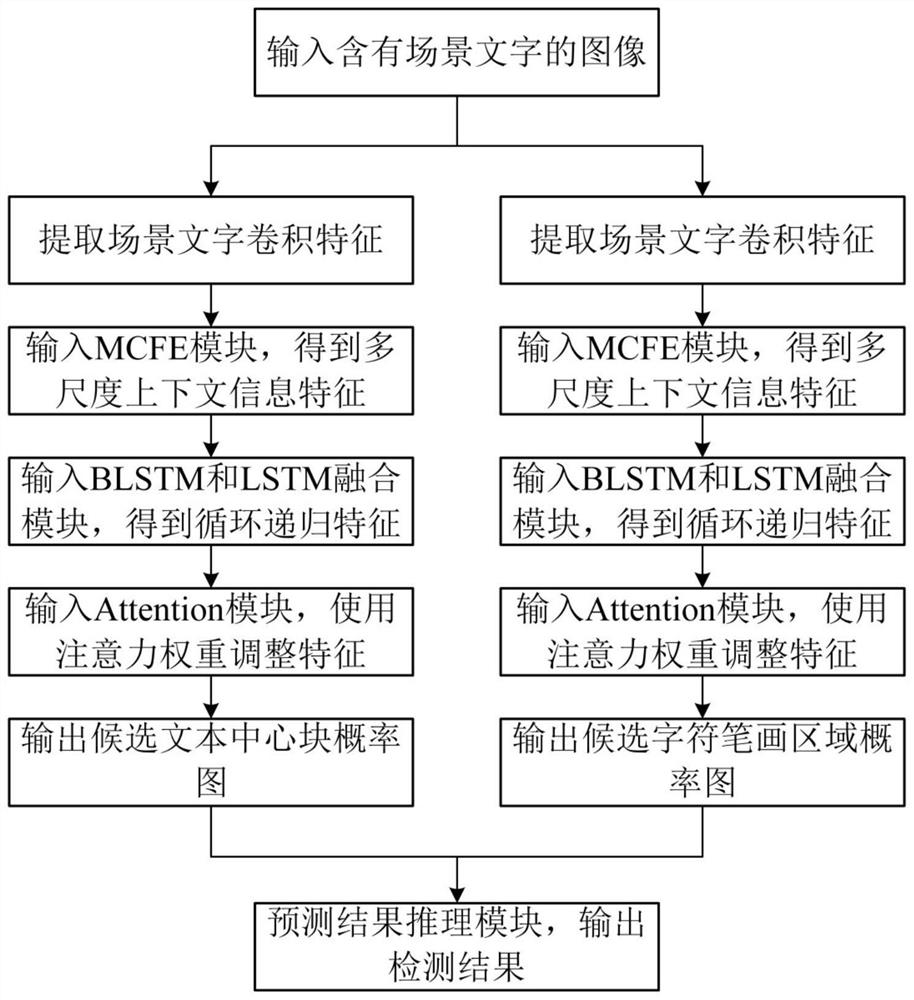

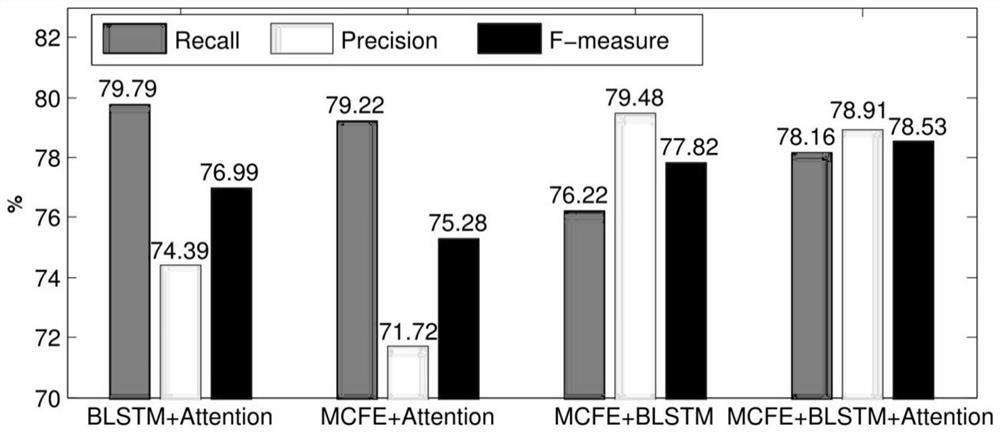

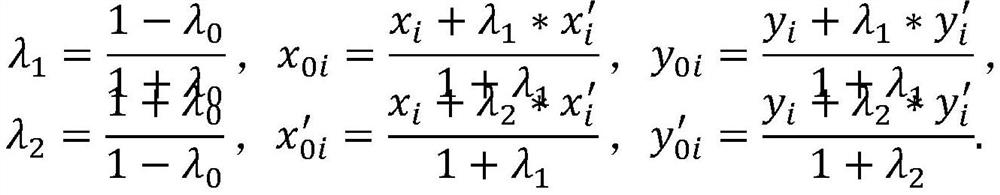

Natural scene character detection method based on attention mechanism

PendingCN114241470ANot easy to returnCharacter and pattern recognitionNeural architecturesText detectionInformation design

The invention discloses a natural scene character detection method based on an attention mechanism, and the method comprises the steps: designing a convolutional neural network model for extracting a text target according to the feature information of a text center block and a stroke region, and training the model through employing the text center block and stroke information as supervision data; in a model test stage, respectively inputting a test image into the text center block model and the stroke model to obtain a probability graph of a text center block and a word stroke area; a final text area is obtained through reasoning and marked, and a scene image text detection task is completed; according to the method, the problems that in the prior art, in scene character detection, direction information of a curved text is not prone to regression, adhesion between adjacent different text lines and information redundancy generated by multi-level feature integration occur are solved.

Owner:XINJIANG NORMAL UNIVERSITY

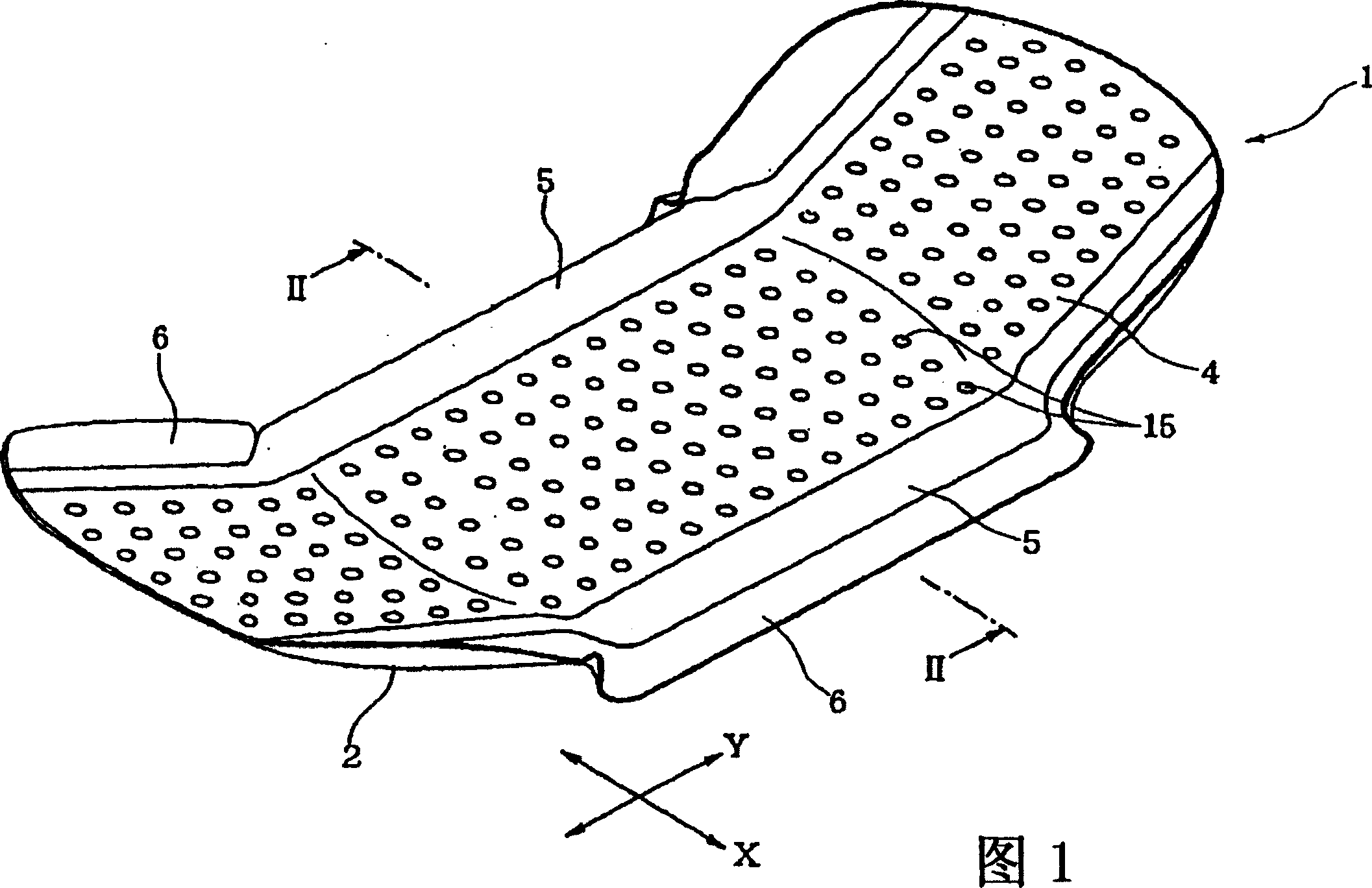

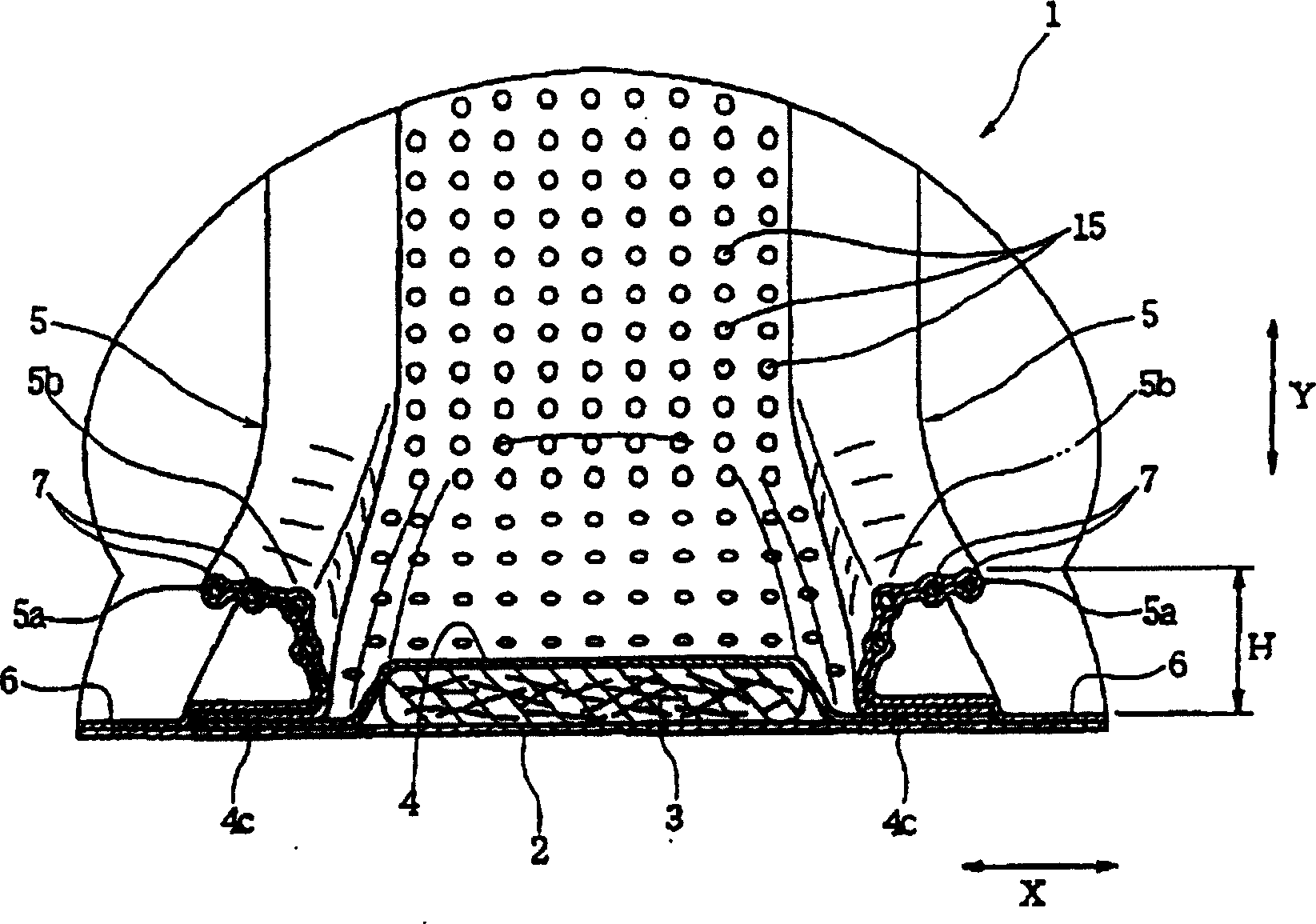

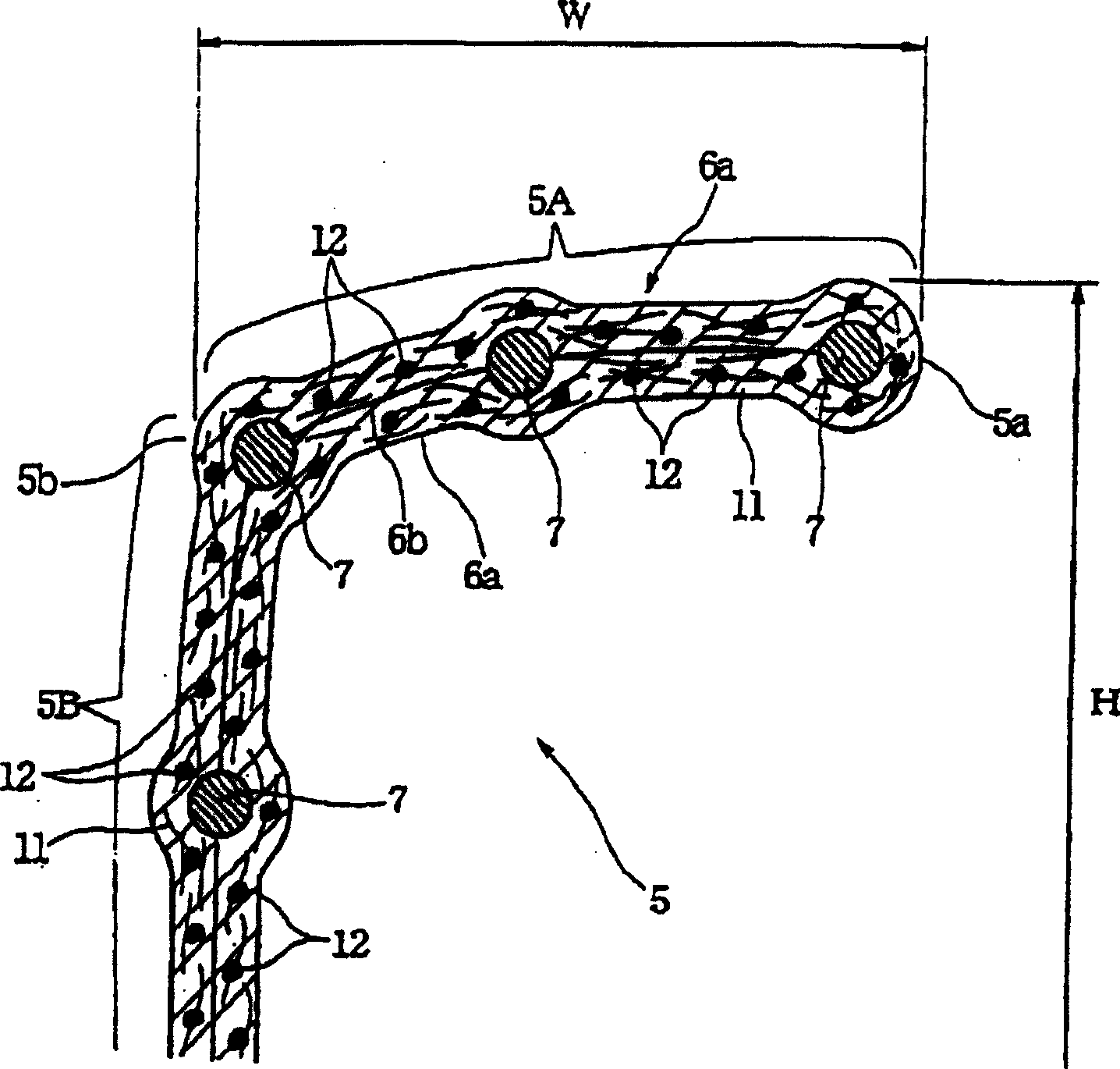

Absorbing article

In conventional sanitary napkins, a small amount of liquid or sweat tends to remain on the leak-proof side wall, and the user feels wet. In the absorbent article of the present invention, the non-woven fabric sheet (6) forming the leak-proof side wall (5) of the sanitary napkin is formed of hydrophobic synthetic fibers (11) with a fiber length of 38 to 64 mm, and dispersed therein An aggregate (12) of hydrophilic fibers such as cotton with a fiber length of 5 to 25 mm, the aggregate (12) is in the shape of a block or crimp. A small amount of liquid on the surface of the anti-leakage side wall (5) is kept by the assembly (12) of hydrophilic fibers. Therefore, it is easy to keep the surface of the anti-leakage side wall (5) in a dry state, reducing the wet feeling on the surface of the anti-leakage side wall (5), and the user has no discomfort.

Owner:UNI CHARM CORP

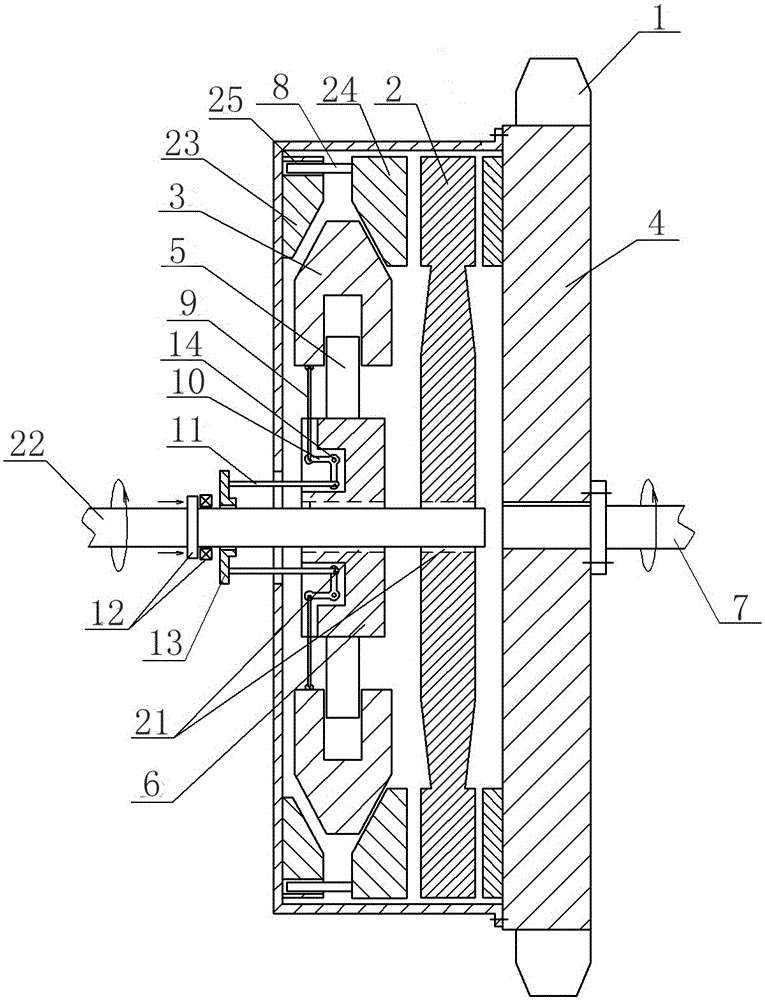

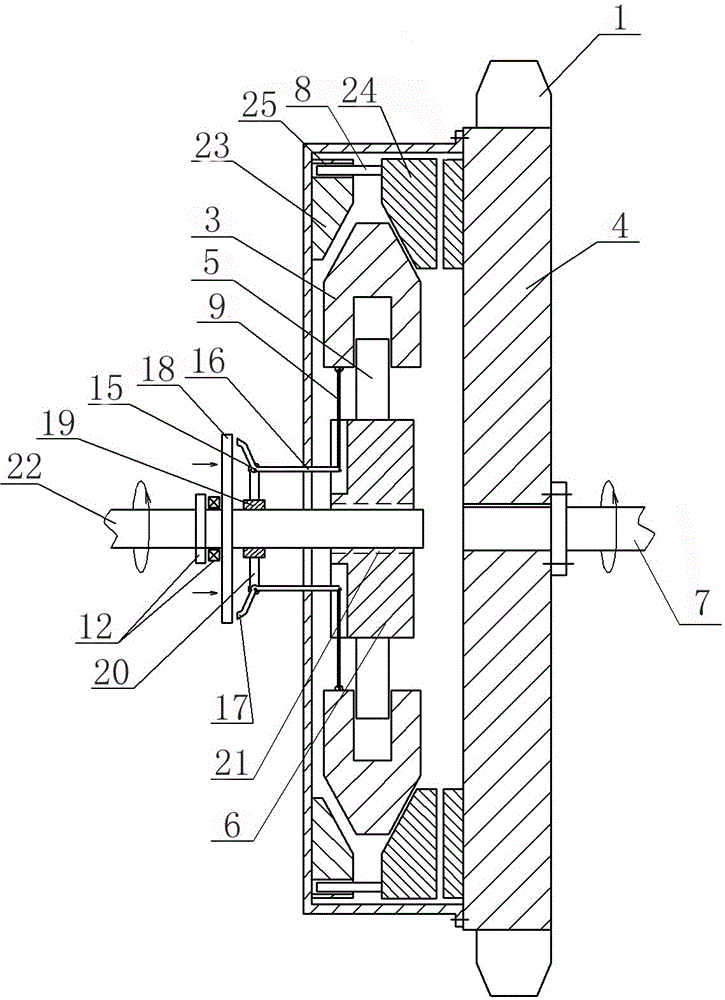

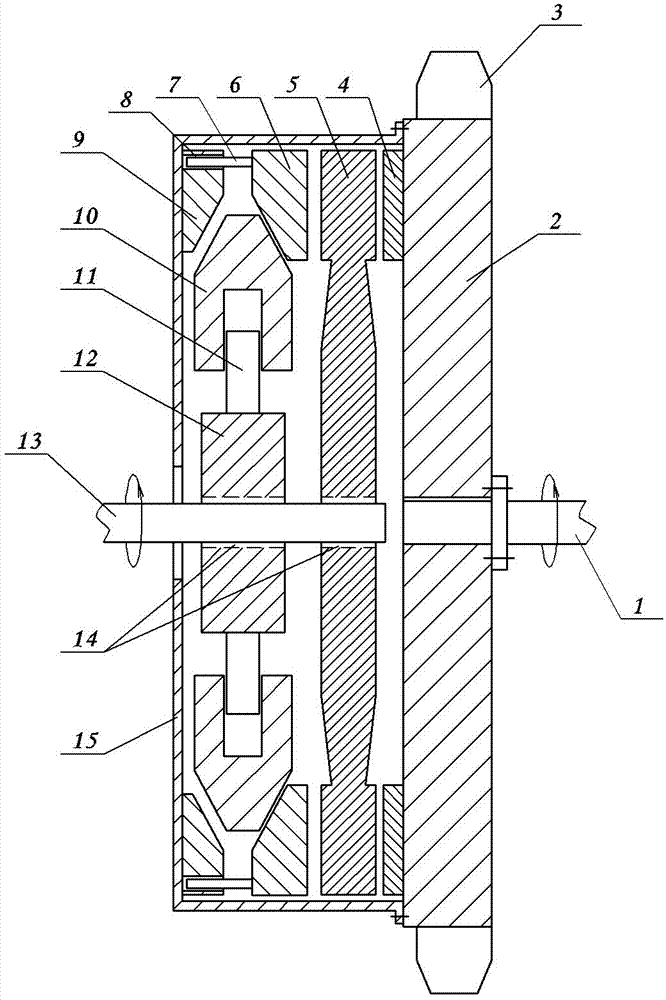

Forced separation centrifugal pressure plate

InactiveCN103089848BImprove performanceNot easy to returnAutomatic clutchesCentrifugationAxial pressure

The invention discloses a forcible separation centrifugal pressure plate which comprises a pressure plate body, a driving part, a centrifugation body and a driven part and the like. A fixed block and a sliding block are arranged on the inner circle of the pressure plate. A cone-shaped opening is formed in the inner edges of the fixed block and the sliding block. The outer edge of the centrifugation body is arranged to be a cone-shaped protrusion. The cone-shaped protrusion and the cone-shaped opening can be arranged together in a matching mode. The sliding block is directly matched with the driven part in a mode of friction, or a friction disc is arranged on one side, close to the driven part, of the sliding block. A forcible traction mechanism capable of enabling the centrifugation body to move inward in the radial direction is arranged on the driving part or on a rotary shaft of the driving part. According to the forcible separation centrifugal pressure plate, radial pressure of the centrifugation body is converted to axial pressure, pressure of a friction surface is enabled not to be changed easily, load with large torque can be transmitted, influence of speed changing is almost avoided, and the problem of friction heating before reaching rated rotating speed is almost not considered. The forcible separation centrifugal pressure plate further solves the problem that gear shifting is difficult to an engine in a high-speed running process.

Owner:杨勇

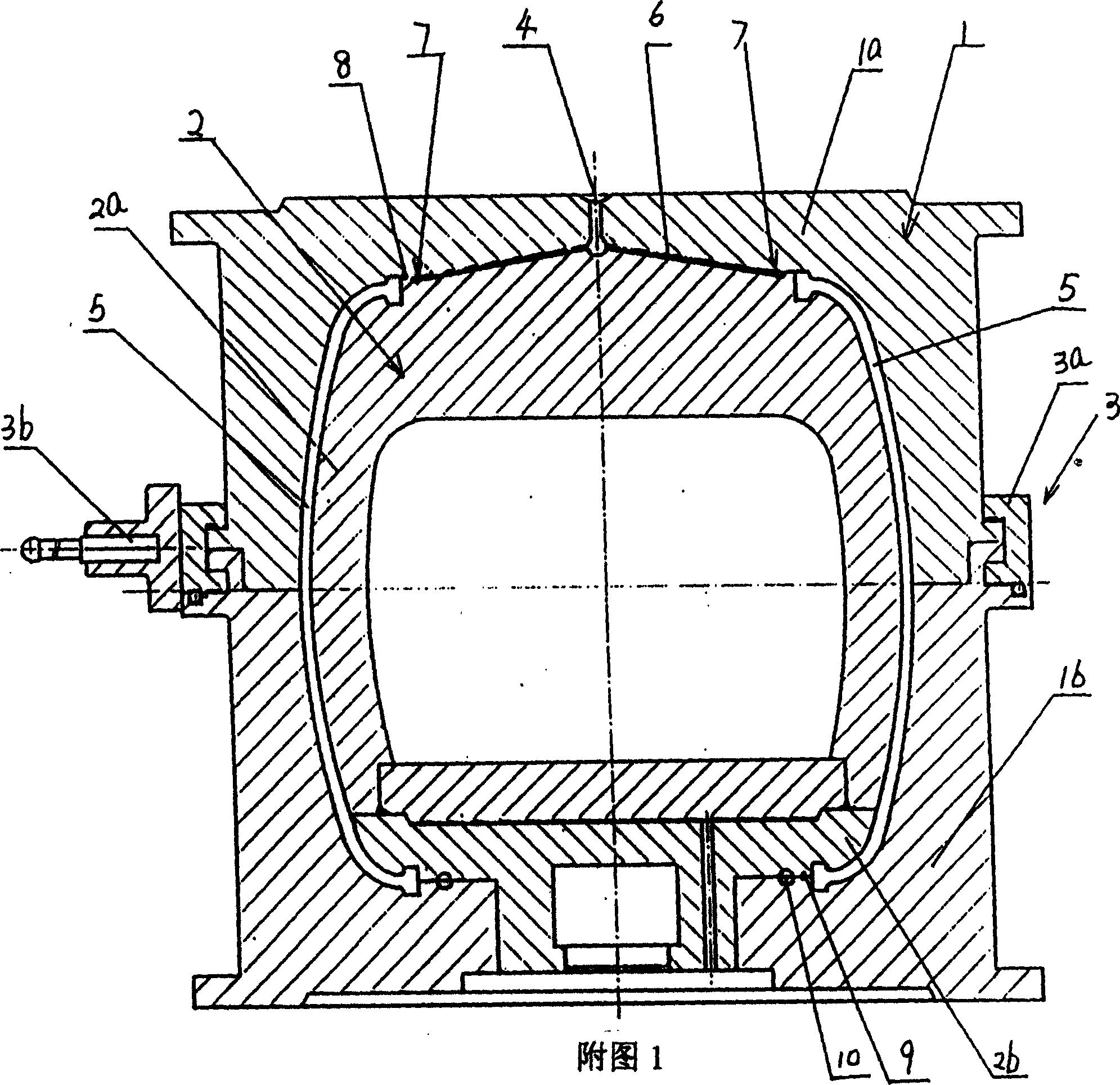

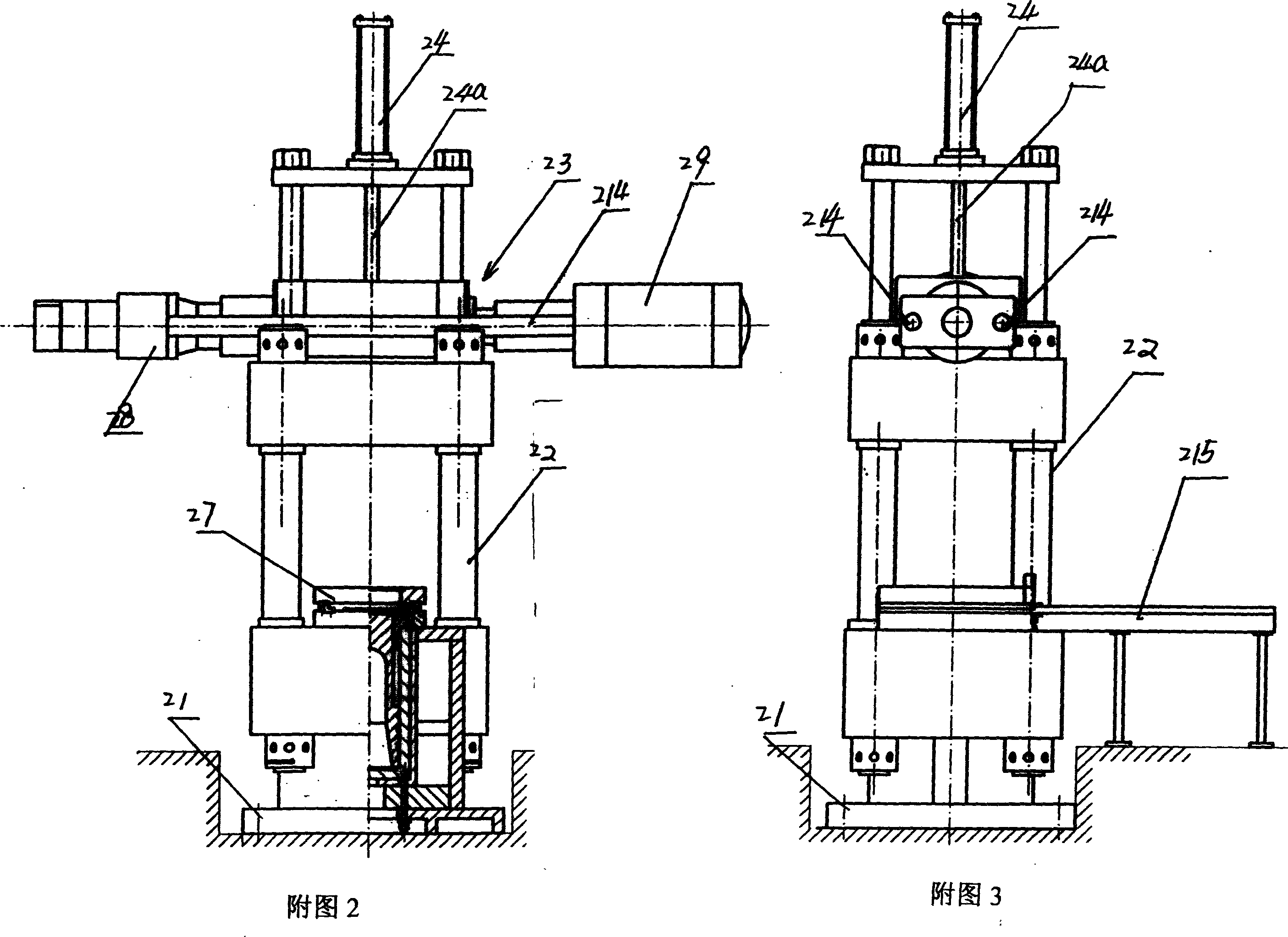

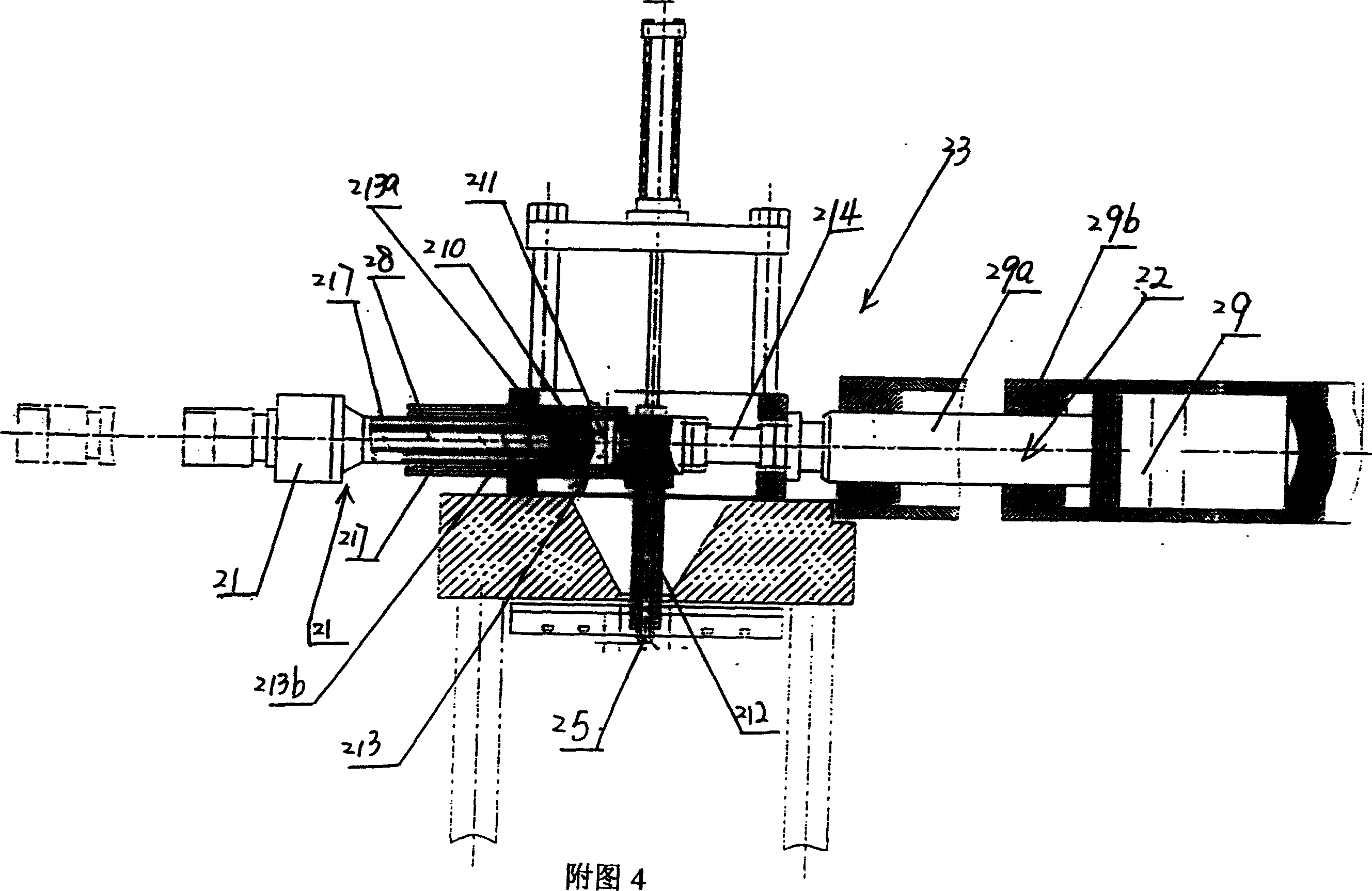

Apparatus for moving mould injection and hot nitrogen far infrared sulfurization of tyre

The invention is a device for sulfurizing tyre capsule with mold shift injection and hot nitrogen far infrared method. The device includes following parts: A assembles capsule pouring mold; B uses mold shift back pushing type injection former to inject rubber into the capsule mold; C uses far infrared to heat the capsule to sulfurize the capsule injected mold; the efficiency in the invention is high. And the capsule sulfurizing pot is arranged with a far infrared heater as the heat source, replaces the heat source when using boiler to produce water steam, thus the boiler can saved out. The device is compact, and it saves a lot of area, it is very convenient.

Owner:青岛国人橡胶研究院有限公司

Centrifugal pressure plate automatic clutch

InactiveCN103089850BImprove performanceHigh friction and stabilityAutomatic clutchesCentrifugationAxial pressure

The invention discloses a centrifugal pressure plate automatic clutch which comprises a pressure plate, a driving part, a centrifugation body and a driven part. A fixed block and a sliding block are arranged in the pressure plate. A cone-shaped opening is formed in the inner edges of the fixed block and the sliding block. The outer edge of the centrifugation body is arranged to be a cone-shaped protrusion. The cone-shaped protrusion and the cone-shaped opening can be arranged together in a matching mode. One side, close to the driven part, of the sliding block is matched with the driven part in a mode of friction through a friction disc or is directly matched with the driven part in the mode of friction. According to the centrifugal pressure plate automatic clutch, radial pressure of the centrifugation body is converted to axial pressure, pressure of a friction surface is enabled not to be changed easily, load with large torque can be transmitted, influence of speed changing is almost avoided, and the problem of friction heating before reaching rated rotating speed is almost not considered. The centrifugal pressure plate automatic clutch is reasonable in structure, and good in using effect, and can be popularized and implemented conveniently.

Owner:杨勇

In Vitro Countercurrent Regeneration of Ion Exchange Resin

ActiveCN104003478BDoes not affect productionRealize continuous productionWater/sewage treatment by ion-exchangeIon exchange beds cleaning/rinsingIon exchangeWater flow

The invention provides an extracorporeal upflow regeneration process for ion exchange resin. The process includes the following steps that firstly, soft water is produced, and meanwhile exhausted resin is continuously discharged from the lower portion of an ion exchanger; secondly, the exhausted resin is conveyed to a gathering tank through injection, conveying fluid is drained from the upper portion of the gathering tank, and the exhausted resin is discharged from the bottom of the gathering tank and enters a regeneration tank; thirdly, regeneration fluid flows into the lower portion of the regeneration tank, upflow regeneration is conducted on the exhausted resin, and regenerated resin is discharged from the bottom of the regeneration tank and enters a cleaning tank; fourthly, water flows into the lower portion of the cleaning tank, the regeneration fluid left on the regenerated resin is reversely cleaned away, and the cleaned regenerated resin is discharged from the bottom of the cleaning tank and is conveyed back to the ion exchanger through injection. According to the process, the soft water can be continuously produced, energy consumption is reduced, and the equipment utilization rate is increased.

Owner:CHENGDU GRACE FIBER +1

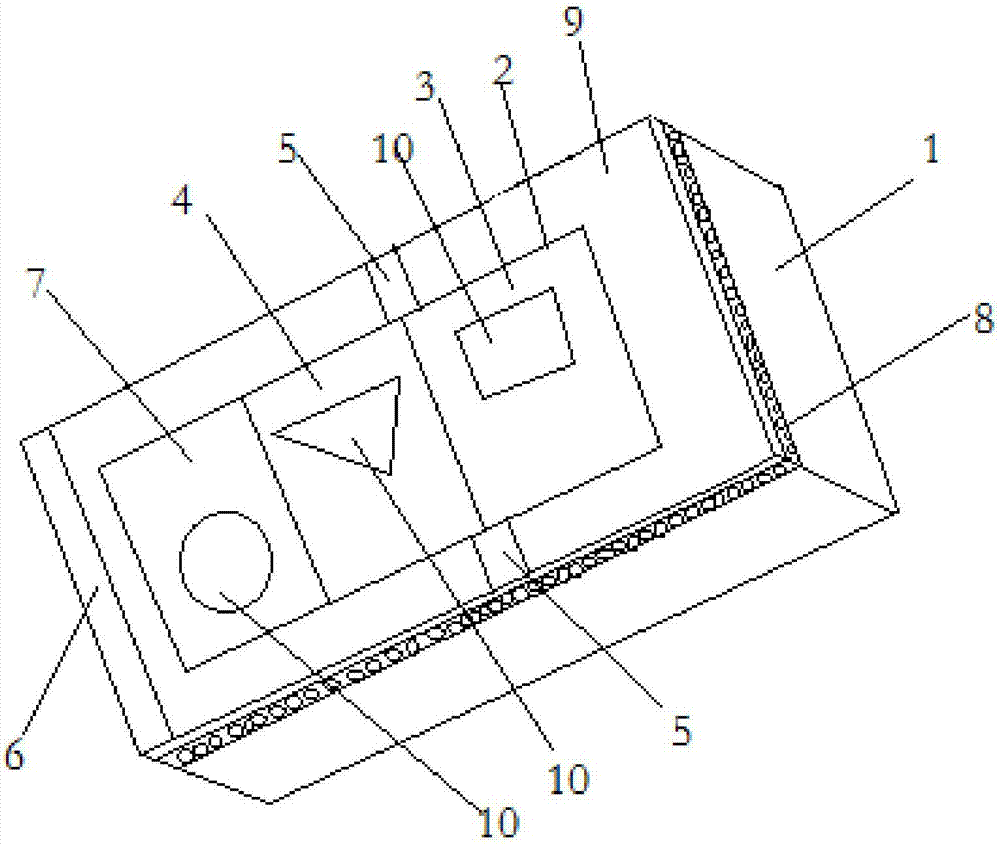

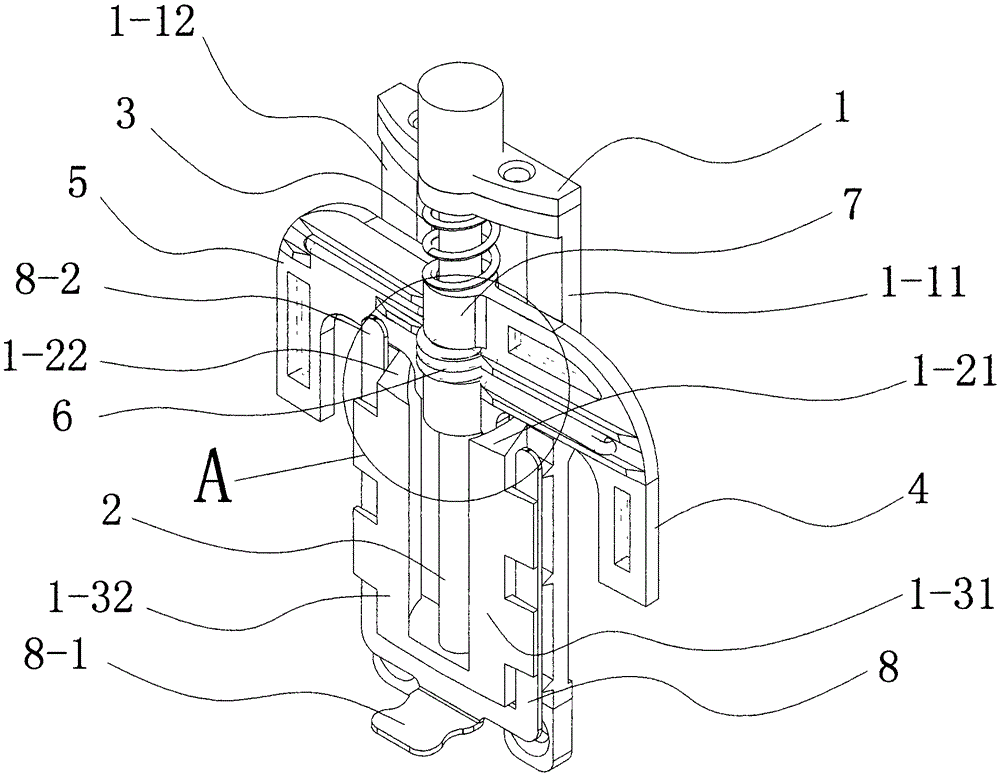

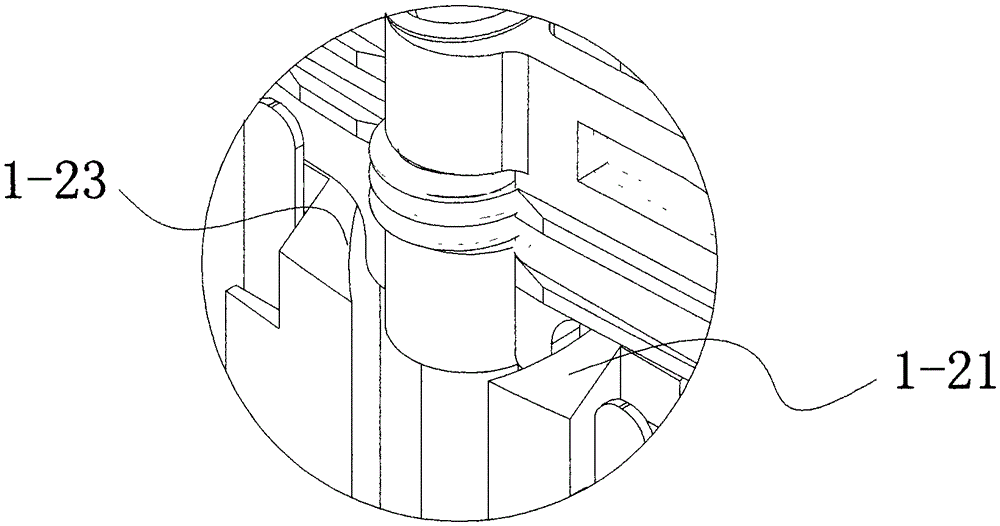

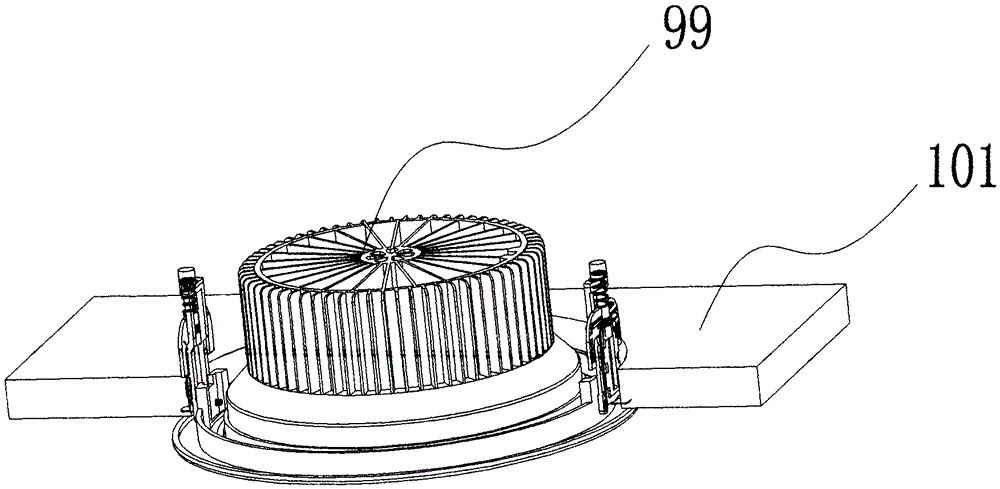

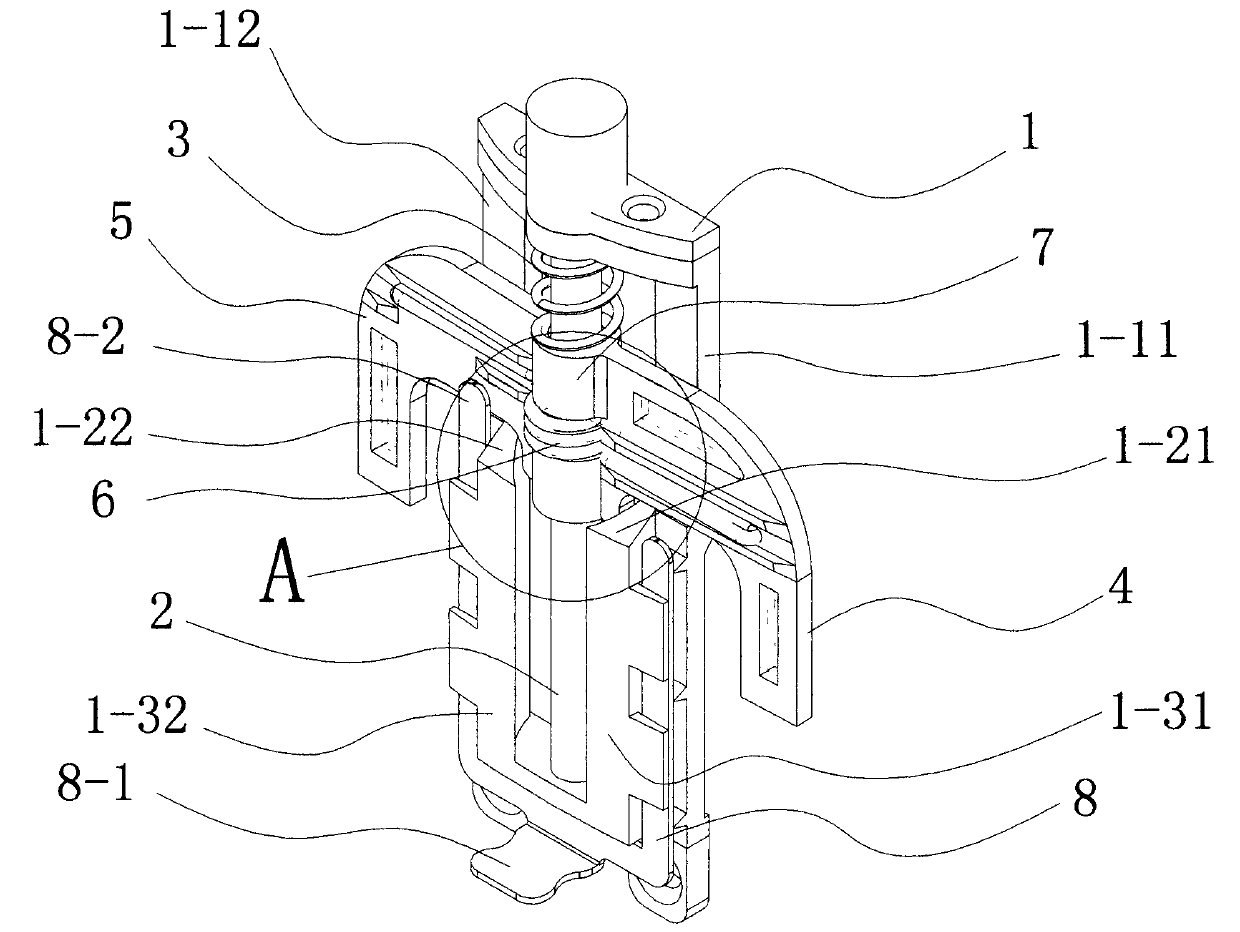

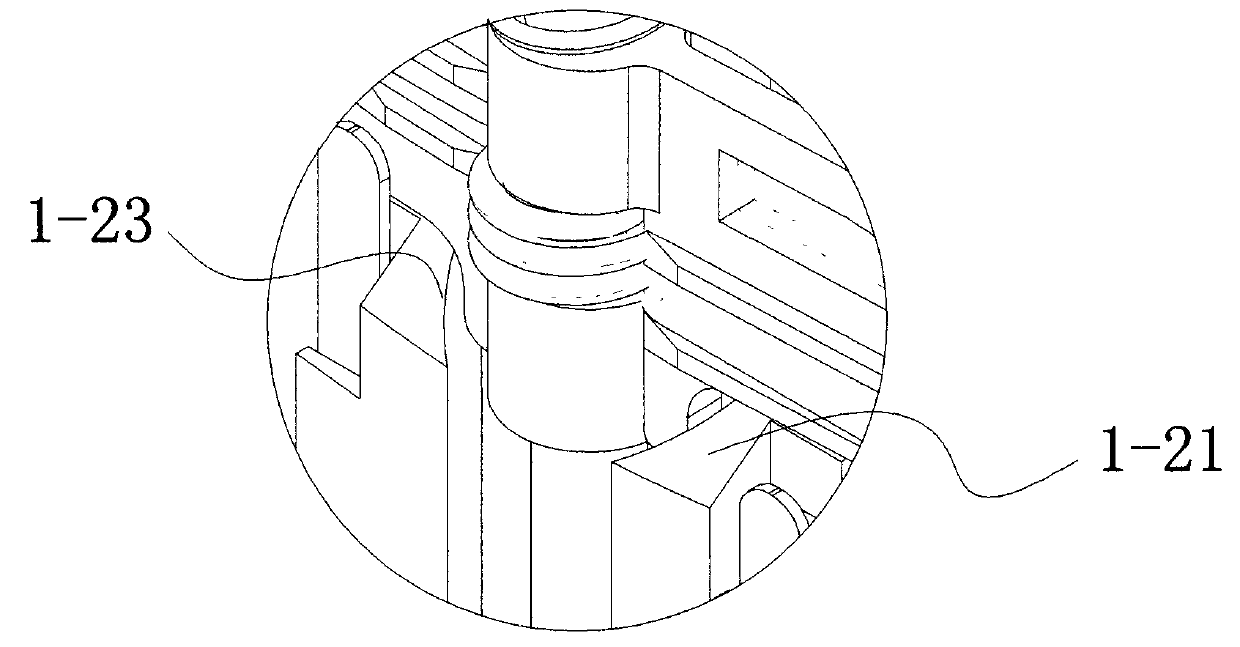

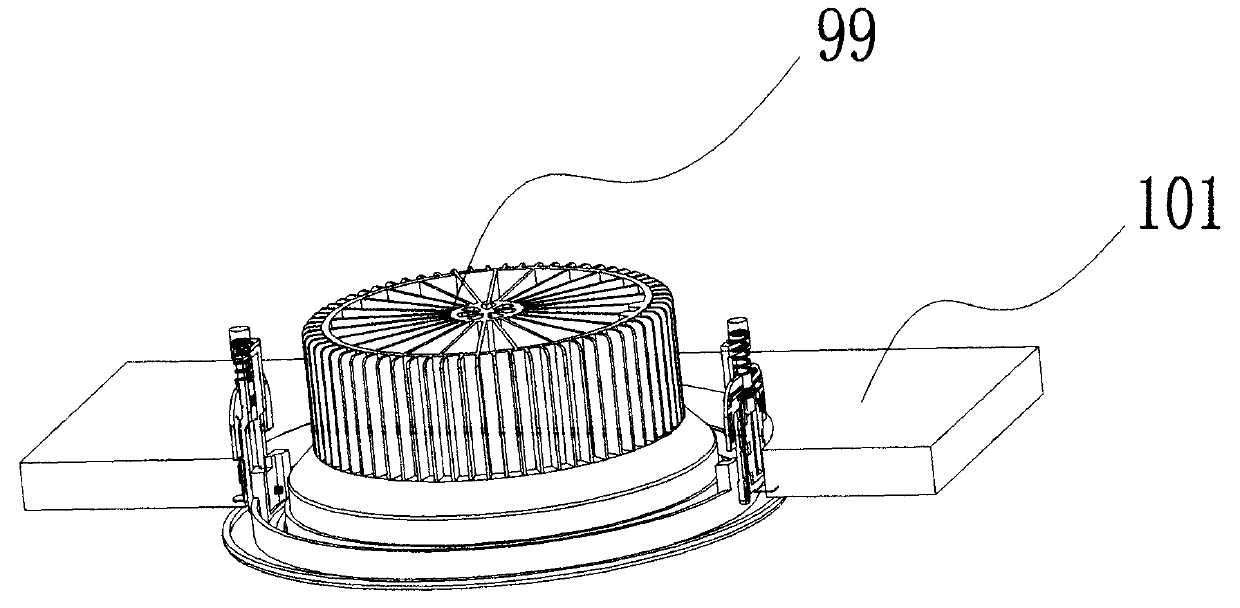

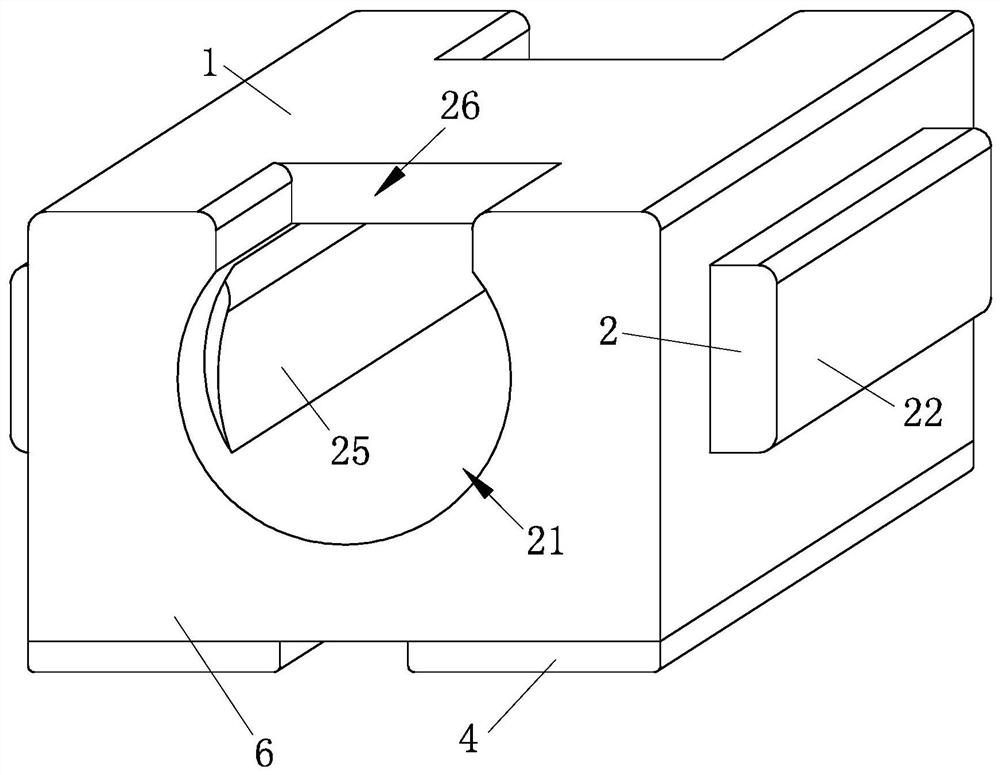

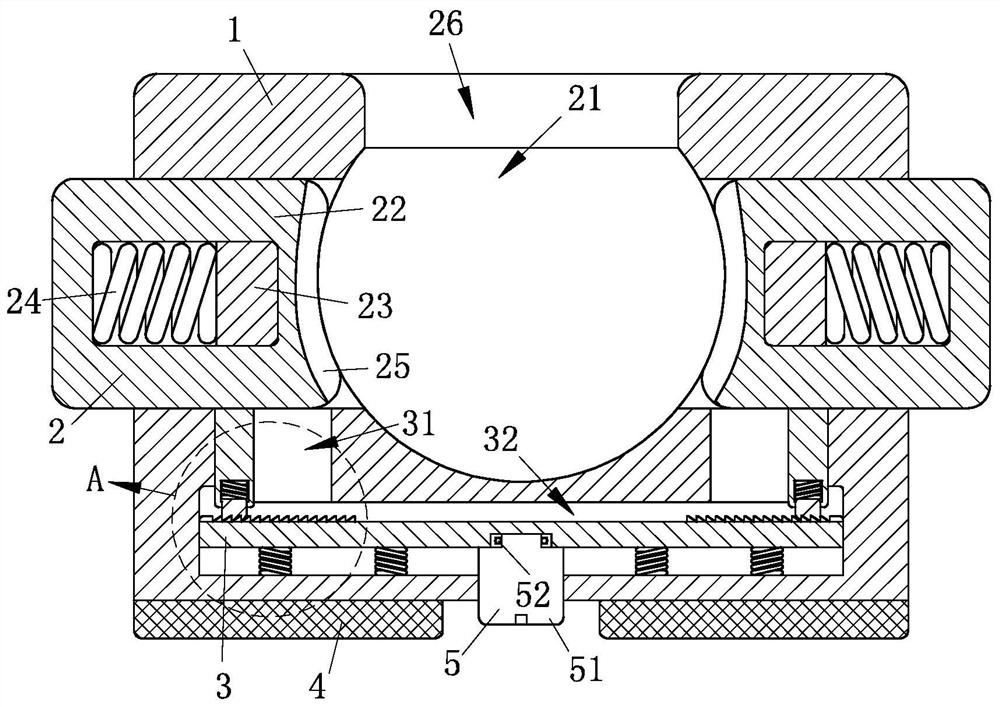

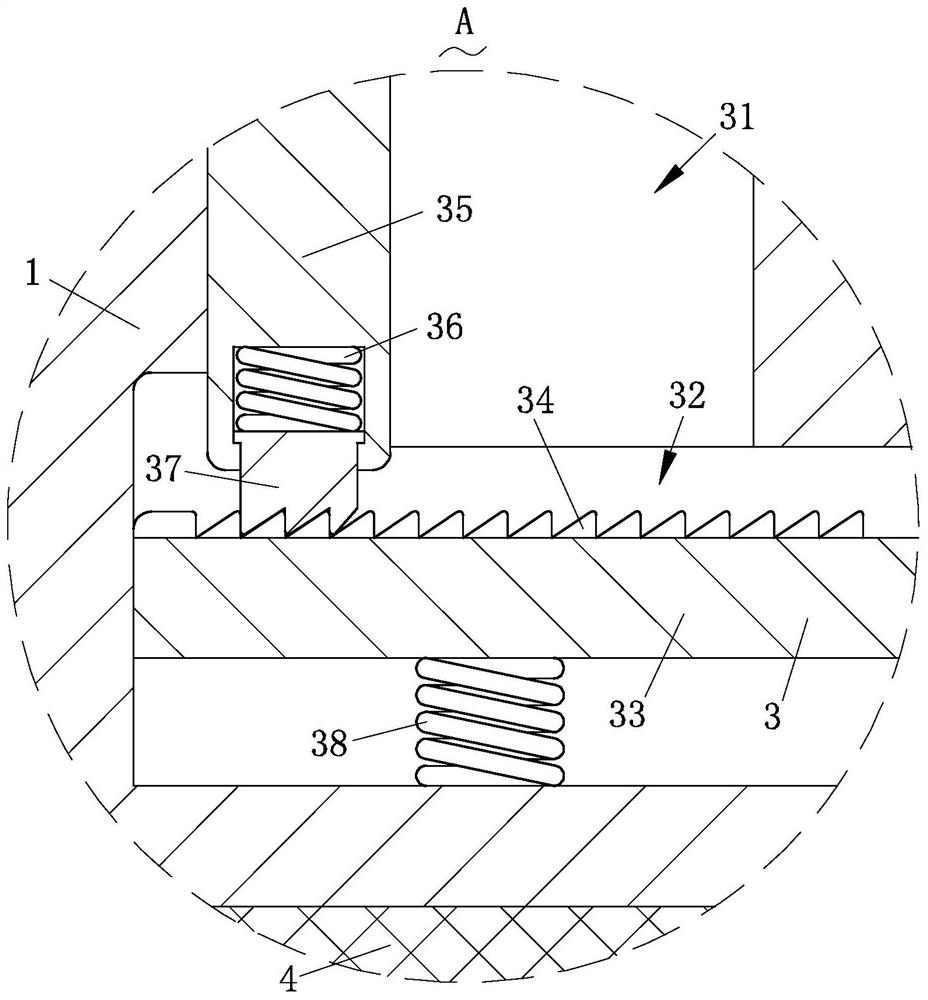

a mounting clip

ActiveCN103994312BEasy to installSimple processMachine supportsLighting support devicesEngineeringMechanical engineering

Owner:DONGGUAN DAEN LIGHTING CO LTD

Installation clamp

ActiveCN103994312ASignificant progressHighlight substantive featuresMachine supportsLighting support devicesWaste management

Owner:DONGGUAN DAEN LIGHTING CO LTD

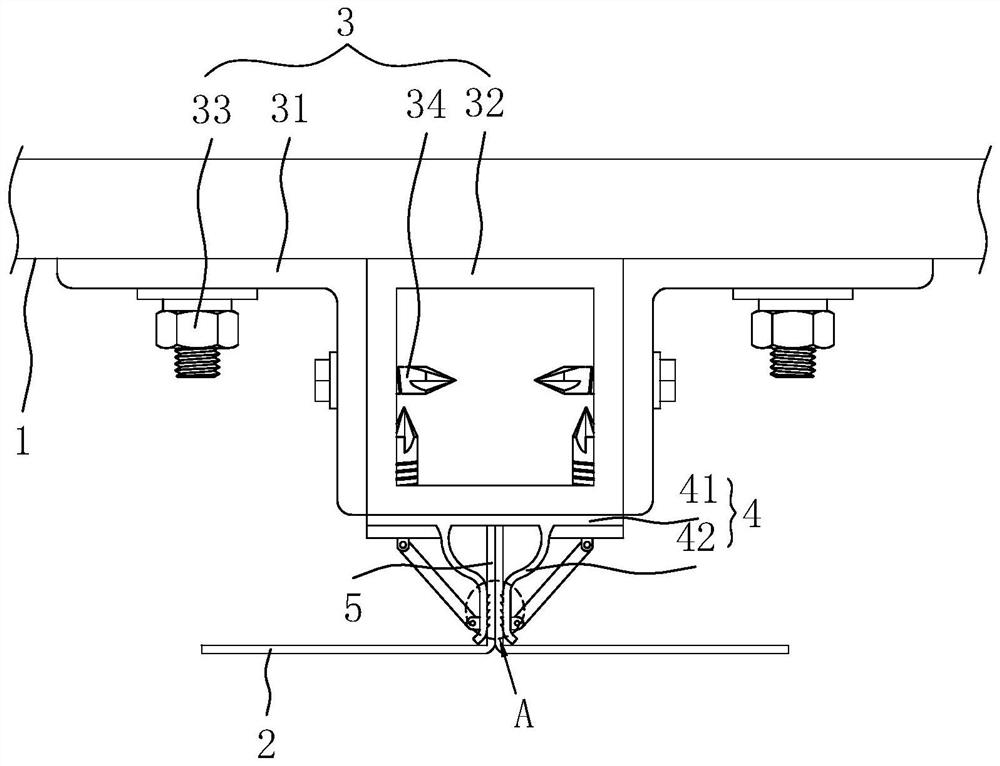

multi-strand wire connector

ActiveCN112736510BStrong conflictNot easy to loosen and fall offElectric connection structural associationsClamped/spring connectionsClassical mechanicsEngineering

The invention discloses a multi-strand electric wire connector, which comprises a fixed seat, a clamping mechanism, an interference mechanism, a sliding groove, a pressing groove, a pressing plate, tines, a limit block, a compression spring, a rack and an adjusting mechanism. The beneficial effects of the present invention are: through the action of the clamping mechanism, it is convenient to place and clamp and connect the multi-strand wires, thereby facilitating the connection of the circuit, and at the same time, the clamping mechanism will drive the limit block to slide inside the chute, While the two limit blocks are sliding, the rack and the tines at the bottom of the limit block are engaged and moved under the action of the compression spring. Since the rack and the tines are in reverse engagement, the rack is not easy to return after moving, which is conducive to clamping When the holding mechanism is clamped, the more it squeezes, the tighter the resistance to the multi-strand wires is, so that the multi-strand wires are tightly connected inside the fixing seat and are not easy to fall off. The clamping mechanism can be loosened to facilitate the removal of multi-strand wires.

Owner:湖南远超环保科技有限公司

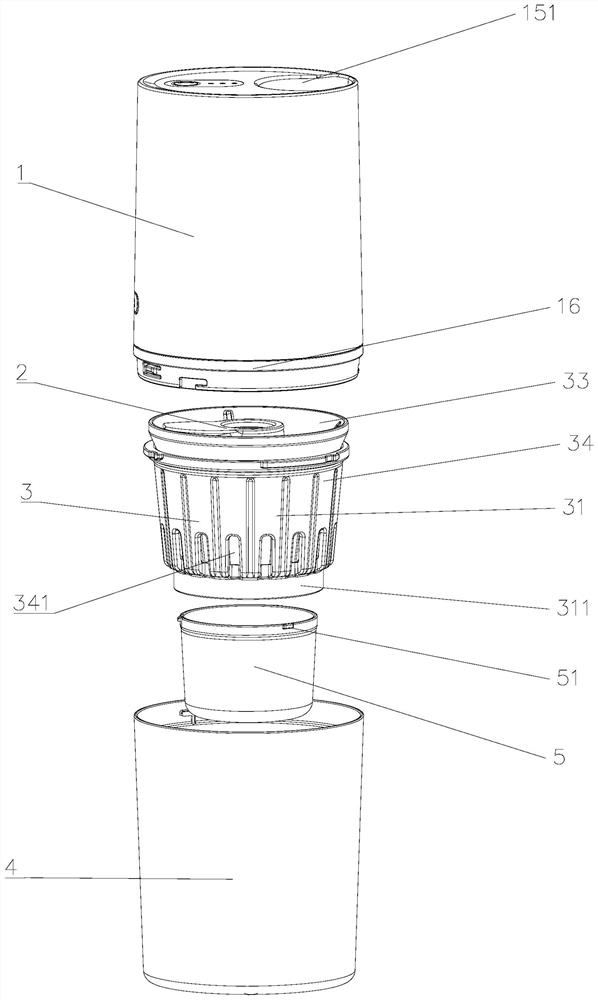

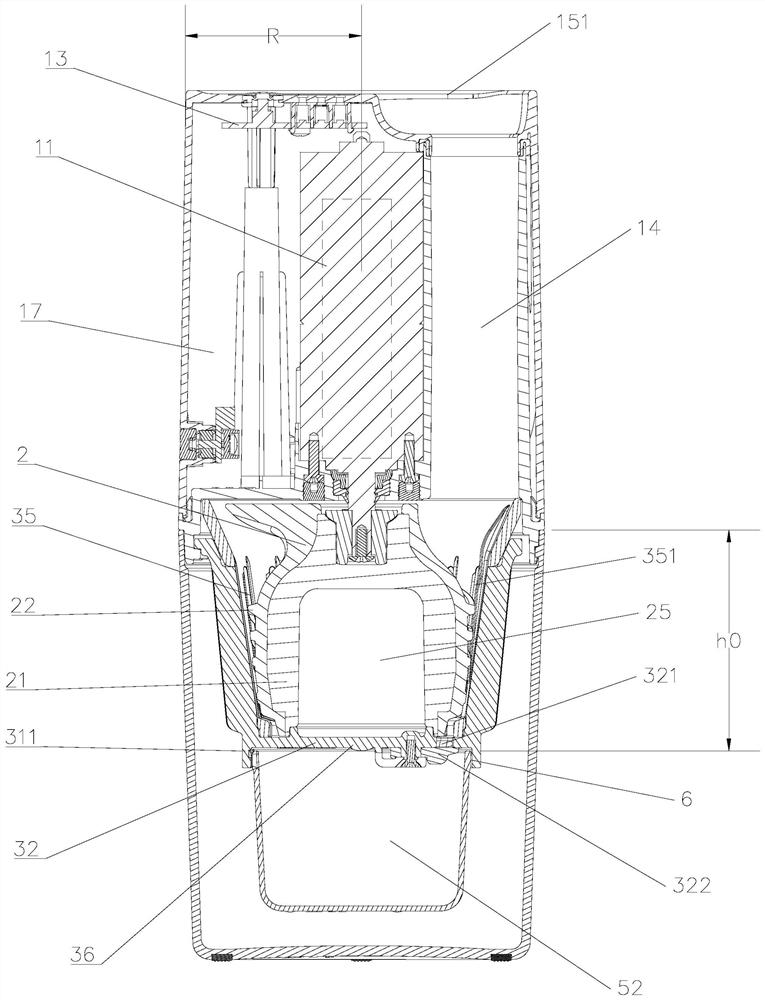

A portable juicer with smooth juice output

Owner:JOYOUNG CO LTD

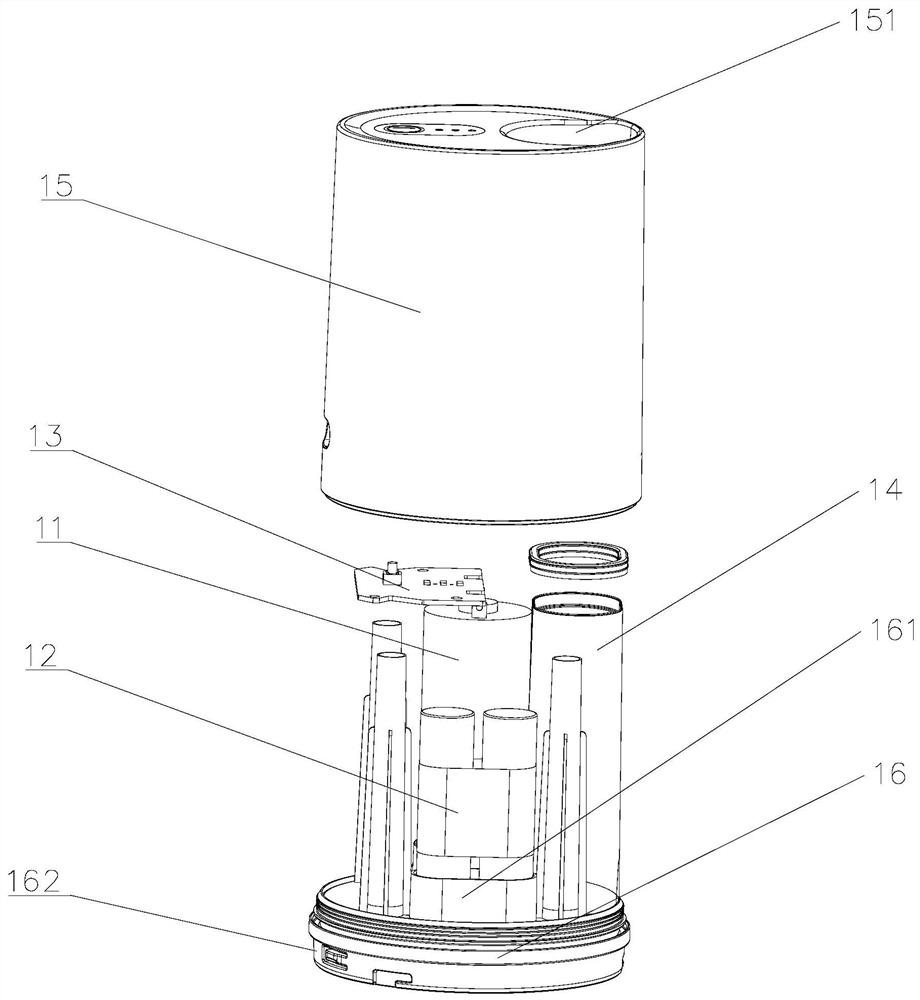

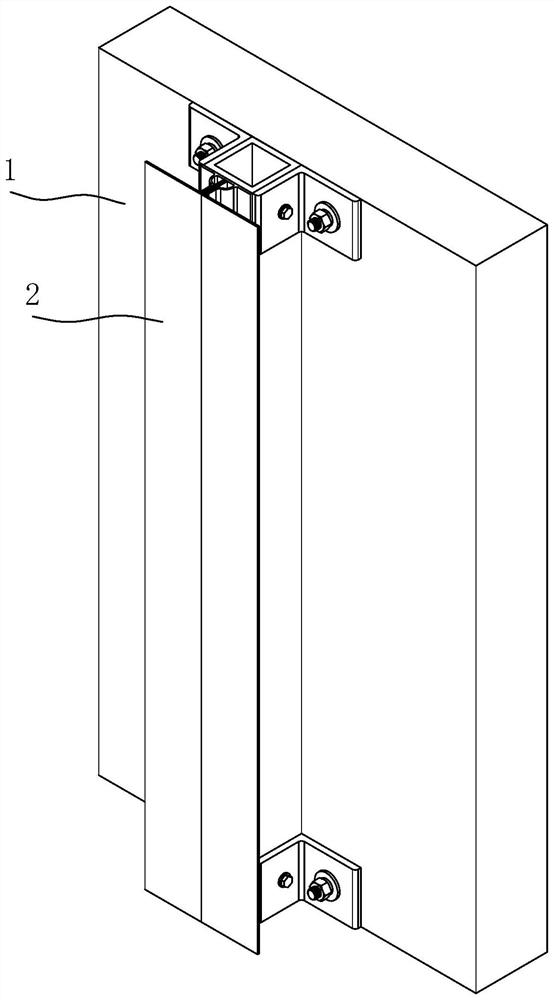

Installation structure and installation method of card-type keel wall panels

ActiveCN111997291BNot easy to break awayImprove bearing capacityCovering/liningsBuilding material handlingEngineeringMechanical engineering

This application relates to the installation structure and installation method of snap-type keel wall panels. It includes a wall surface and a wall panel. Two adjacent wall panels are connected by clip joints. The installation assembly is fixed on the wall. Two elastic clips are arranged on one side of the installation board. The clips are perpendicular to the installation board. The sides of the two clips are equipped with teeth. It is bent to form a connecting plate perpendicular to the wallboard. The two connecting plates abut against each other and are inserted between the two clamping plates. The sides of the two connecting plates facing away from each other are provided with card slots that are adapted to the teeth. The teeth on the two clamping plates are inserted into the slots on the two connecting plates respectively; supporting components are arranged between the mounting plate and the two clamping plates, and when the two connecting plates are inserted between the two clamping plates, , the support assembly makes it difficult for the clamping plate to bend away from the connecting plate. The application has the effects of strong load-bearing capacity of the wallboard, high structural stability of the wallboard and convenient construction.

Owner:SHENZHEN ARTISTIC BUILDING MATERIALS

A powder spreading device for 3D printer

ActiveCN113118471BReduce pollutionReduce recycling workloadAdditive manufacturing apparatusComputer printingStructural engineering

The invention discloses a powder spreading device for a 3D printer. The method of the invention includes: the powder dropping module is installed on one side of the linear motion module, and includes a powder spreading bin, a powder spreading roller, a switch control board, a cam control shaft, and an isolation baffle; the powder spreading bin is provided with a vertical plate, and the lower end of the vertical plate is provided with a vertical plate. It is separated from the bottom of the powder spreading bin; the powder spreading roller is placed between the lower end of the vertical plate and the bottom of the powder spreading bin, and together with the vertical plate, the powder spreading bin is divided into a powder storage bin and a powder dropping bin. In the powder spreading bin, the powder can be transported from the powder storage bin to the powder dropping bin by rotating itself; the switch control board is movably installed in the powder dropping bin, and there is a boss; the cam control shaft is provided with a cam, which is tangent to the boss, and the cam Both ends of the control shaft are movably installed in the powder drop bin; the isolation baffle is placed in the powder storage bin to divide the powder storage bin into an empty bin and a powder bin. The invention can carry out reasonable powder injection according to the amount of parts, reduce the workload of cleaning the powder, improve the iterative speed of product research and development, and improve the research and development efficiency.

Owner:ZHONGBEI UNIV

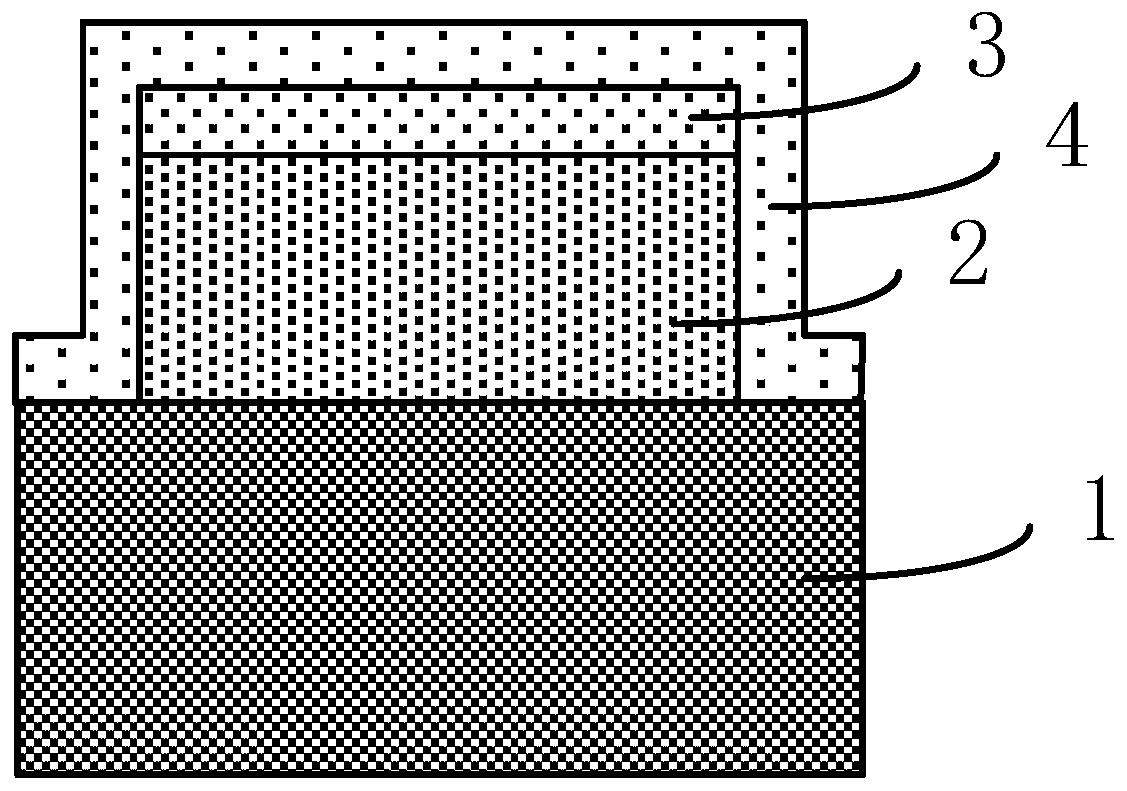

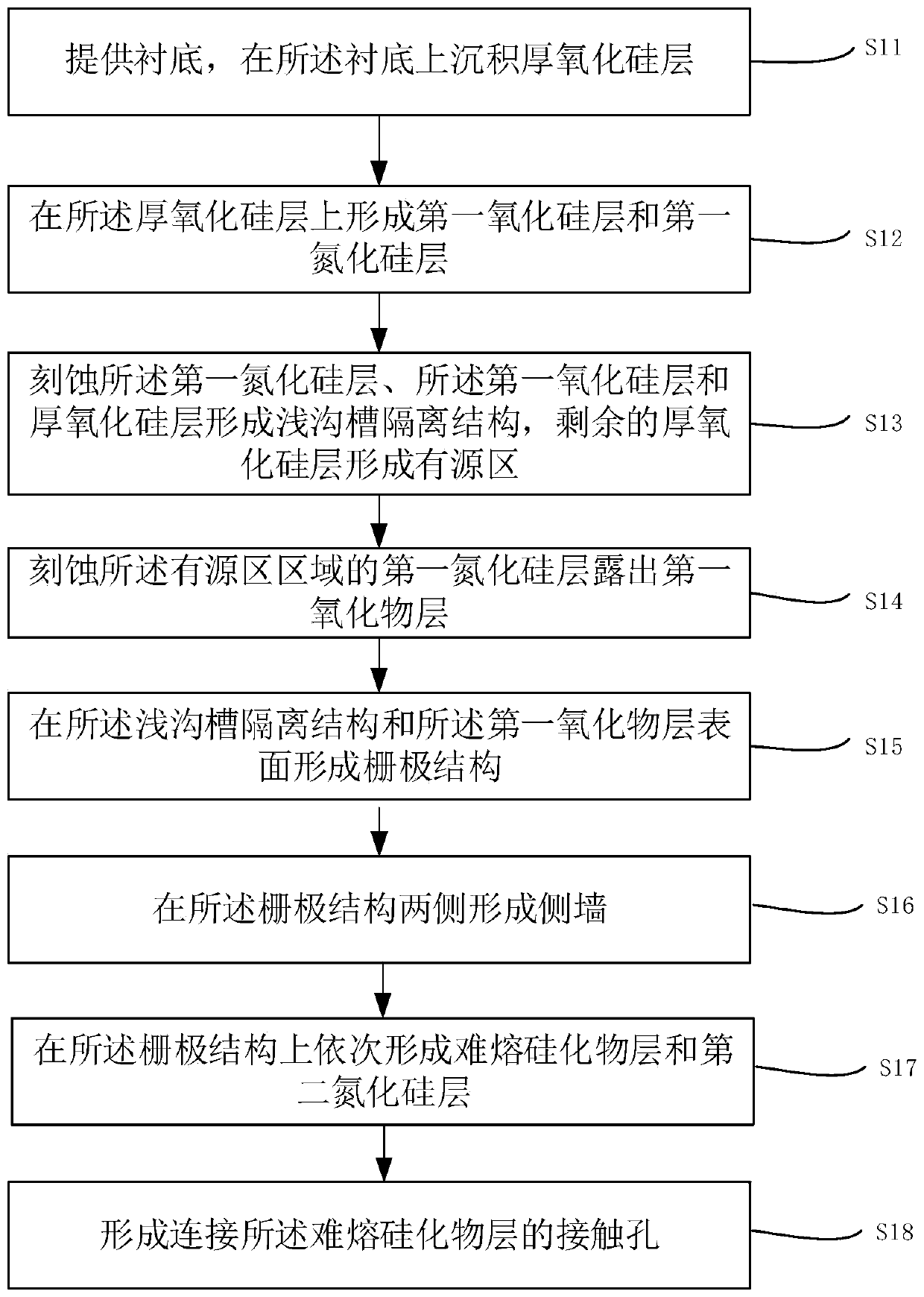

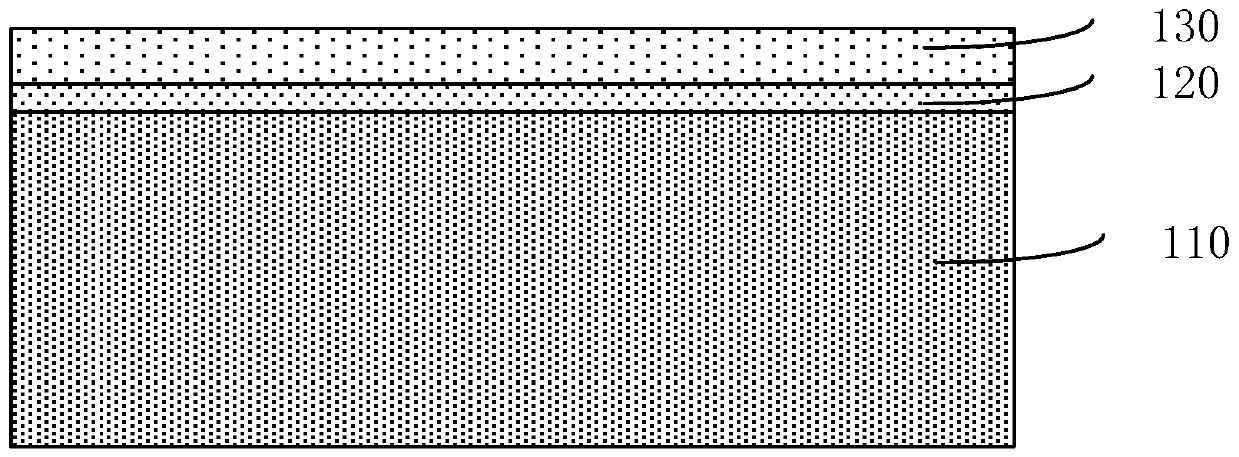

Method for manufacturing one-time programmable device and one-time programmable device

PendingCN111211123AImprove reliabilityPromote migrationSolid-state devicesSemiconductor/solid-state device manufacturingPhysicsSilicon nitride

The invention provides a method for manufacturing a one-time programmable device and the one-time programmable device. The device comprises an active region, a shallow trench isolation structure located on one side of the active region, a first silicon oxide layer located on the active region, a gate structure located on the shallow trench isolation structure and the first silicon oxide layer, side walls located on two sides of the gate structure, a refractory silicide layer, a second silicon nitride layer, and a contact hole, wherein the refractory silicide layer and the second silicon nitride layer are sequentially located on the gate structure, and the contact hole is connected with the refractory silicide layer. A surface of the shallow trench isolation structure is higher than the surface of the first silicon oxide. A cathode end is placed in a shallow trench isolation structure region, an anode end is placed in the active region, the shallow trench isolation structure region andthe active region form a step, the refractory silicide layer also forms the step, and a grain size of the refractory silicide at the step is different from that at a plane so that migration of metal ions at the cathode end is facilitated, the migrated metal ions are not easy to return to the cathode end again, and reliability is improved.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

Method and device for separating sperms

InactiveCN101831383BDifficult to enterNot easy to returnBioreactor/fermenter combinationsBiological substance pretreatmentsRubber ringLow speed

The invention discloses simple and high-efficient method and device for separating sperms. The device consists of an Eppendorff centrifugal tube, a separating tube and a rubber ring. The method comprises the steps of: reasonably controlling the level height of culture solution; and culturing in a 5 percent CO2 culture container at 37 DEG C for 15minutes for separating the sperms. The concentration of the sperms can be adjusted by adopting a low-speed centrifugal method; about 95 percent of obtained sperms have athletic ability; and the collected solution generally has no blood cells. The invention is suitable for an in vitro capacitation experiment.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com