LED factory lamp with air channel optimized through fin group applied to normal temperature state

A technology for LED factory lights and fin sets, which is applied in the direction of cleaning methods using tools, chemical instruments and methods, cleaning methods and utensils, etc., can solve the discount of heat dissipation effect, the deterioration of heat dissipation effect, and the impact on the service life of LED factory lights, etc. problems, to achieve the effect of keeping clean, prolonging service life and good heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

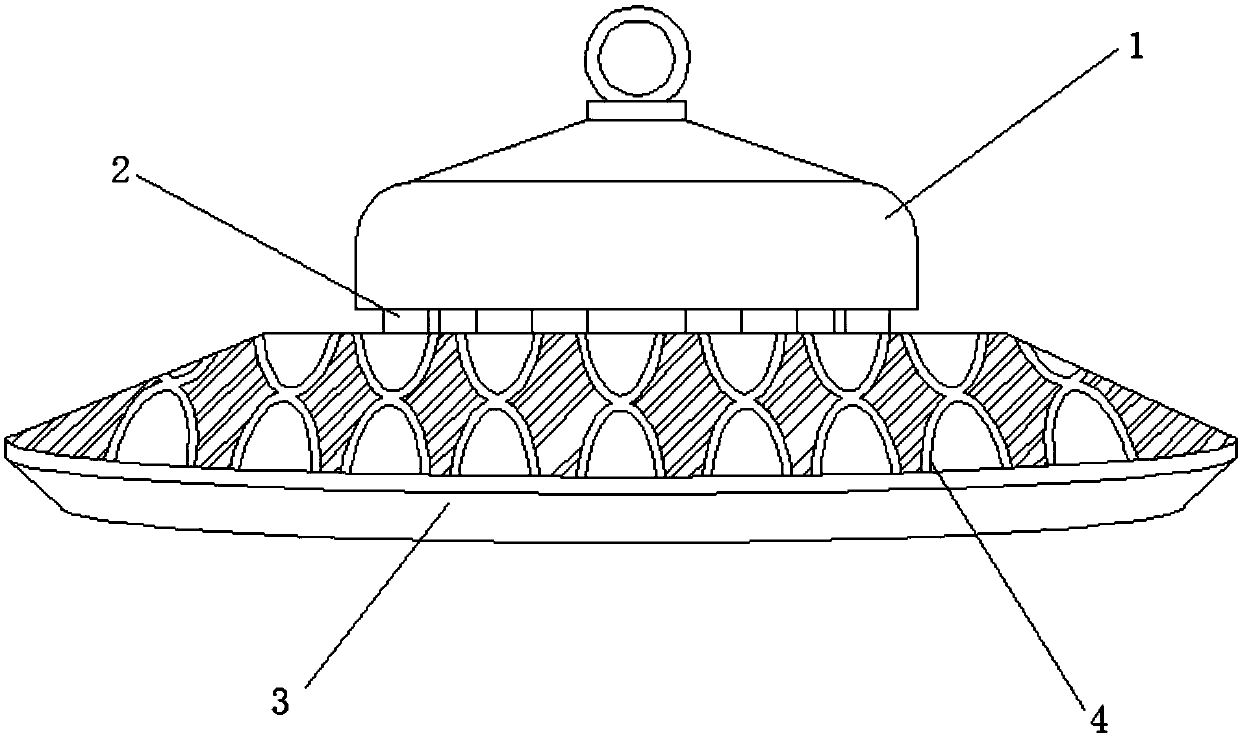

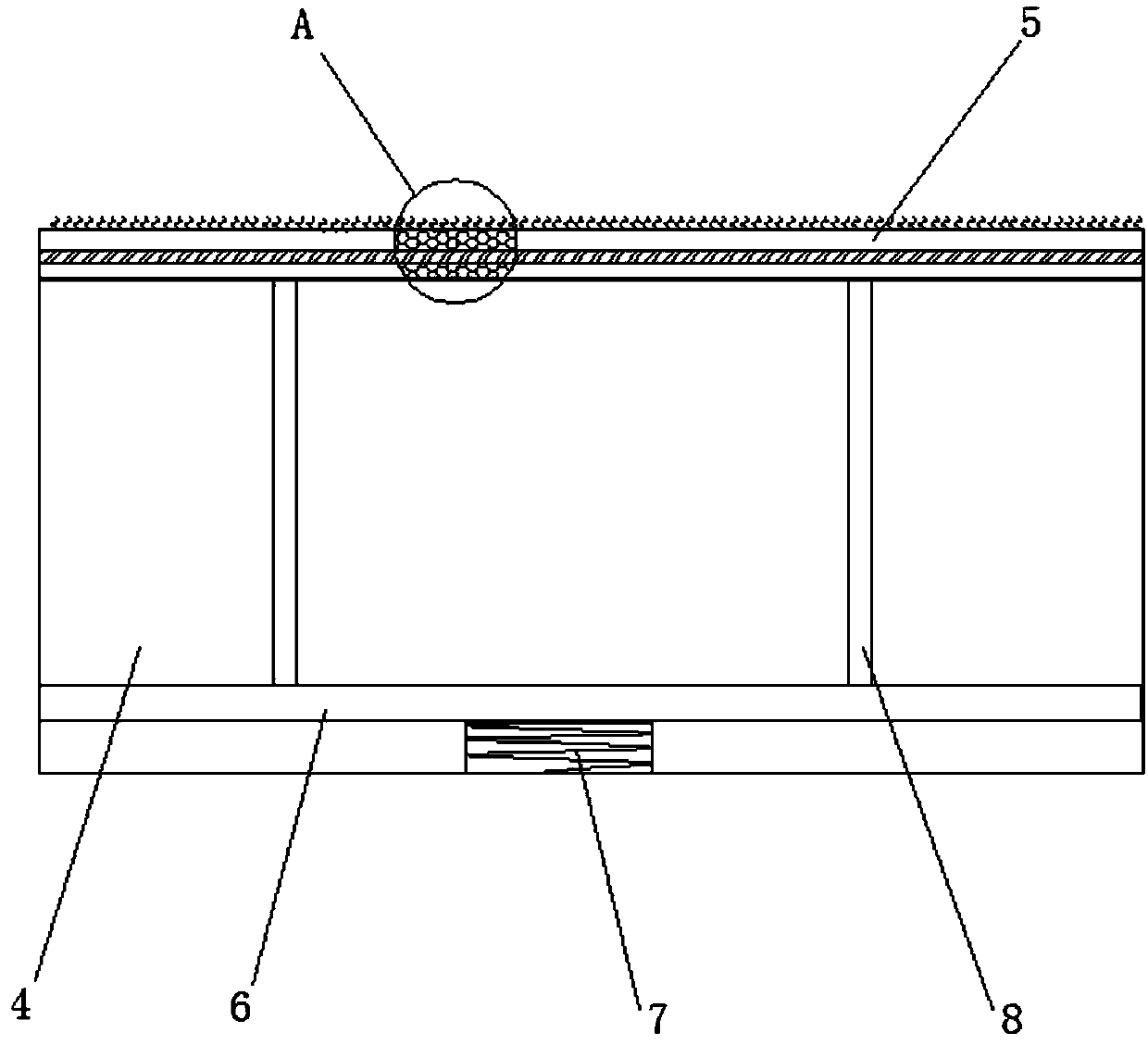

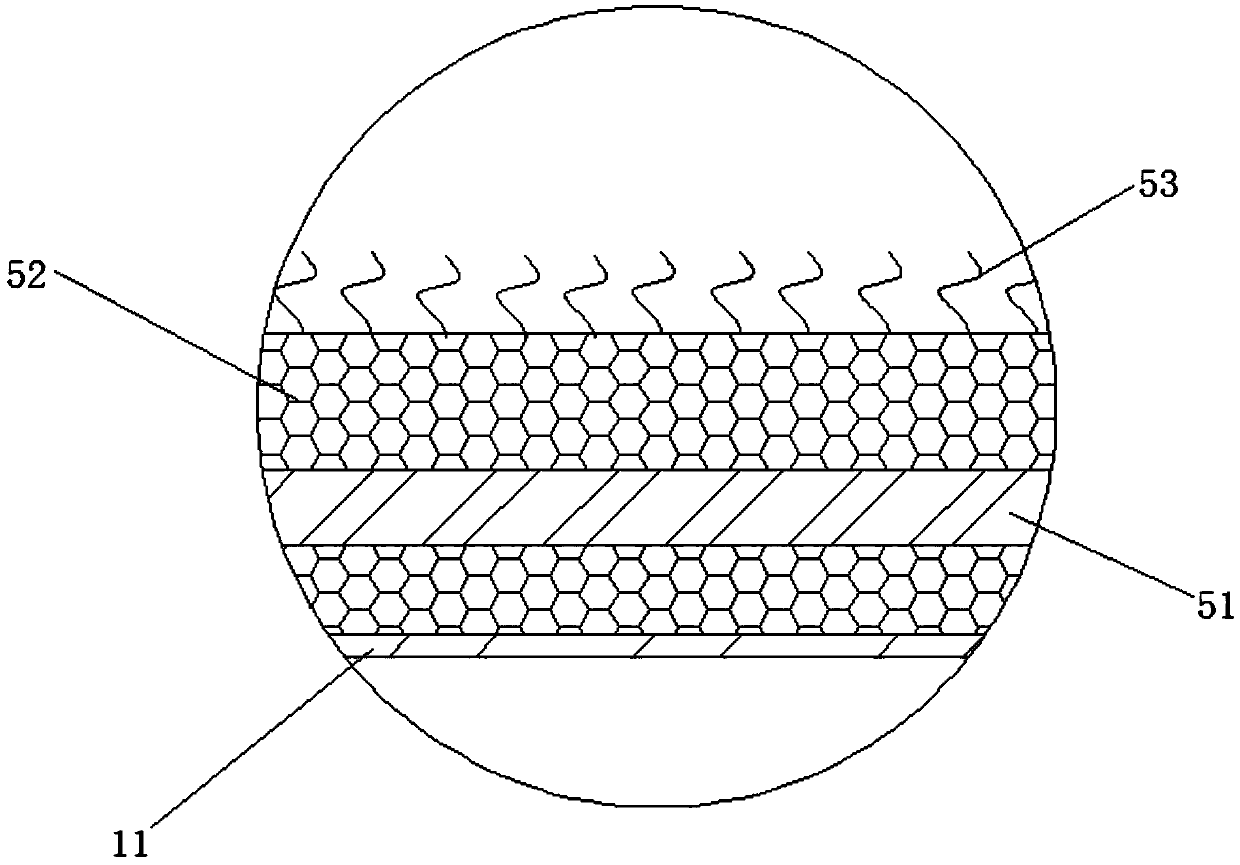

[0043] see figure 1 , a fin group optimized air duct type LED factory light applied at normal temperature, including a lamp holder 3 connected to the lower end of the mounting base 1 through a connecting column 2, and a lamp bead is installed inside the lamp holder 3, and the high temperature resistance of 150 degrees Celsius is selected The Philips LED lamp bead, model: LUXEOMHR30, increases the number of lamp bead particles, reduces the power of a single lamp bead, ensures that the lamp bead will not cause light decay due to continuous high temperature, and effectively guarantees the service life of the entire lamp; the upper end of the lamp holder 3 is set There is an air duct, the air duct includes cooling fins 4, and the cooling fins 4 are fixedly connected to the surface of the lamp holder 3, please refer to figure 2 , both sides of the radiating fin 4 are equipped with a temperature-variable dust removal mechanism, the temperature-variable dust-removal mechanism includ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elongation length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com