Cutting and bending device and membrane cutting and bending method

A bending device and cutting technology, which is applied in the field of cutting and bending devices, can solve the problems of reduced strength of the diaphragm, waste of time and manpower, and easy damage, and achieve the effect of good strength and not easy to return to shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

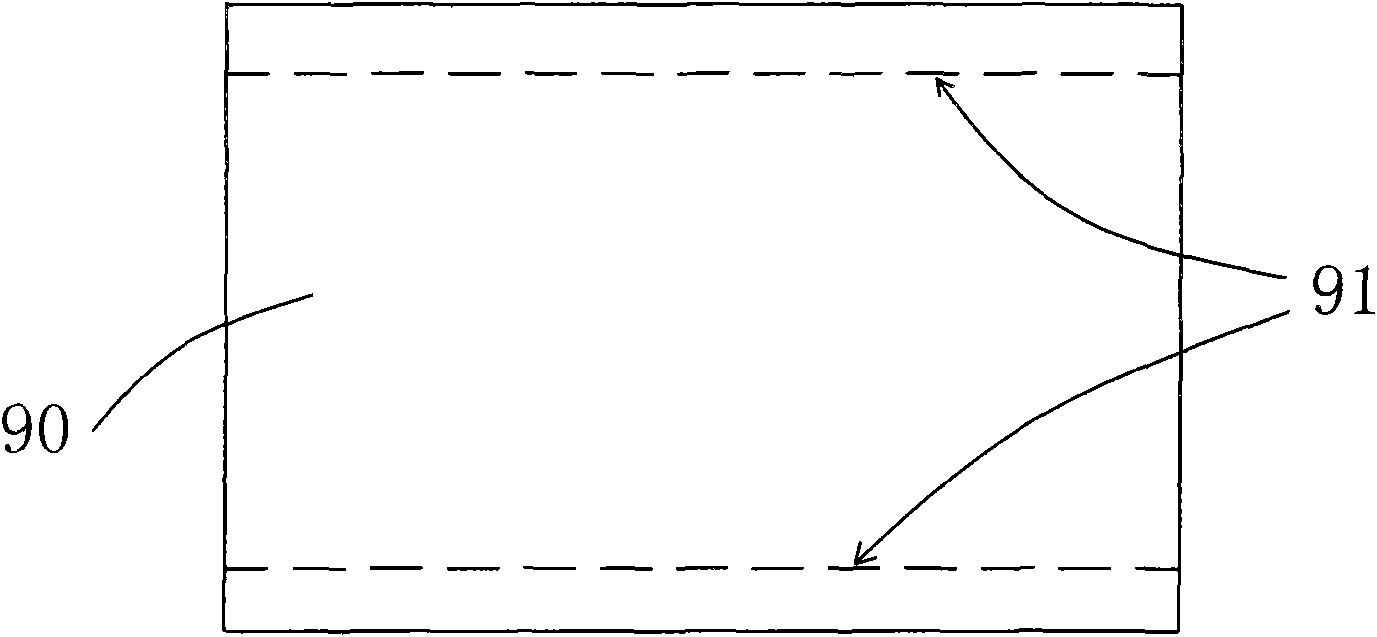

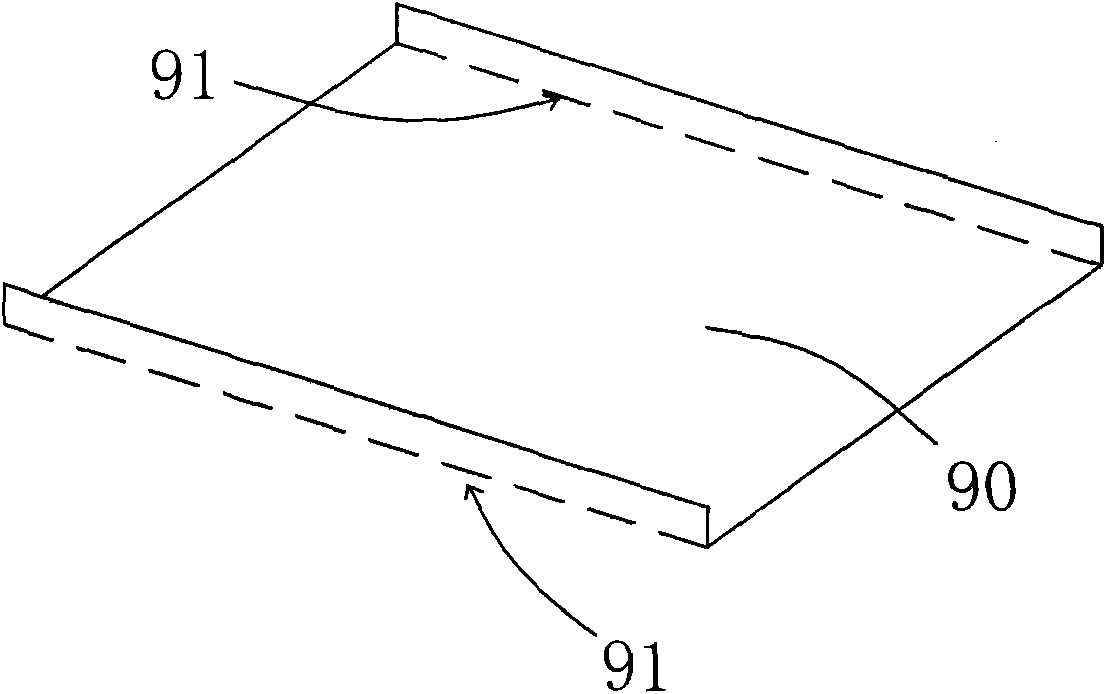

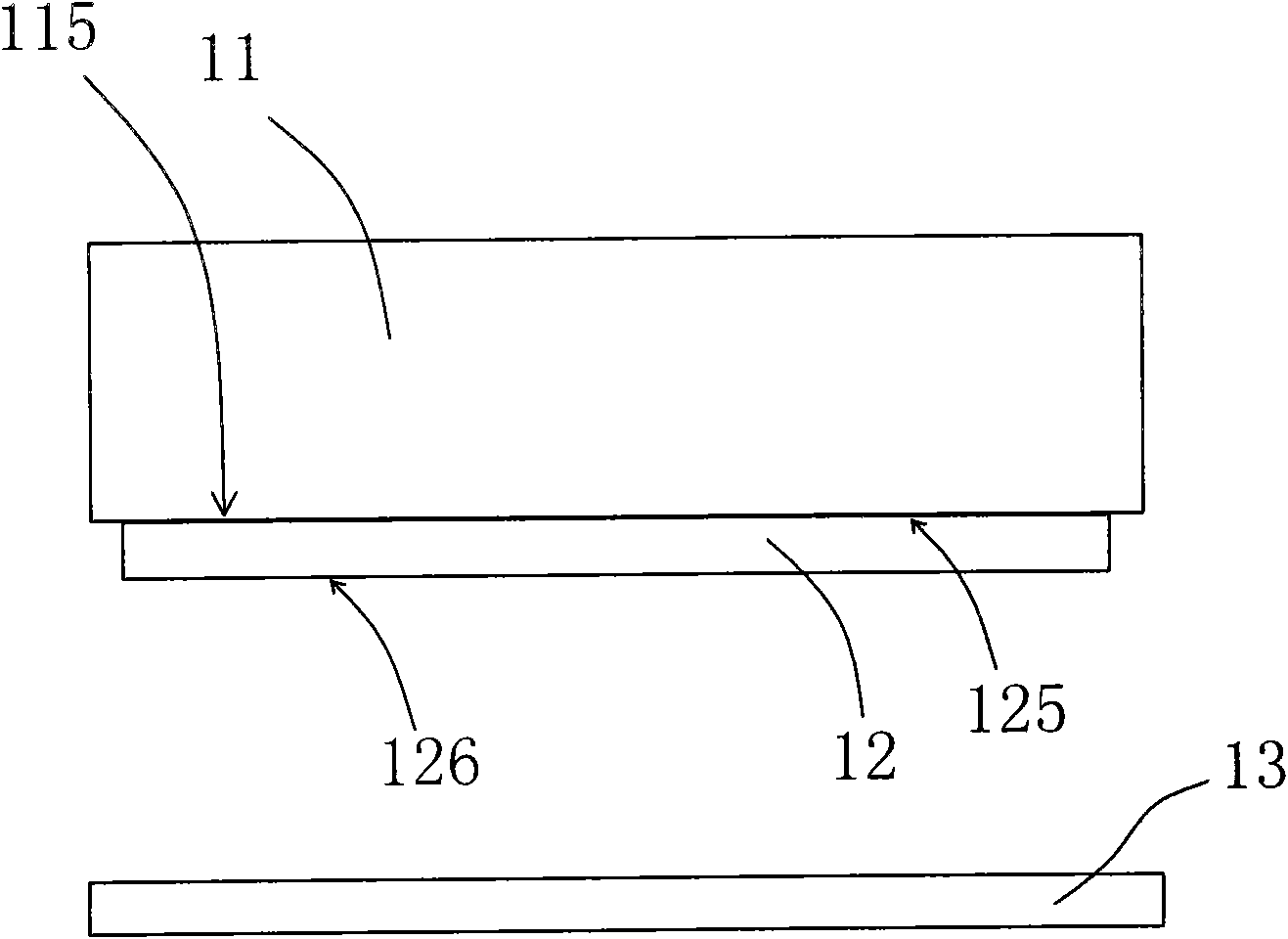

[0019] Please refer to Figure 3 to Figure 6 , image 3 It shows a schematic front view of a cutting and bending device according to an embodiment of the present invention; Figure 4 painted image 3 Schematic diagram of a partially enlarged front view of the cutting die in the cutting and bending device shown; Figure 5 painted image 3 The schematic bottom view of the cutting die in the cutting and bending device shown; Figure 6 painted image 3 A schematic top view of the support table in the cutting and bending device shown. The cutting and bending device of this embodiment includes: a positioning table 11, the positioning table 11 has a positioning surface 115; a cutting die 12 having opposite first surfaces 125 and second surfaces 126, the first The surface 125 is positioned on the positioning surface 115 (it can be positioned by means of screw locking, side strip clamping, etc.); the second surface 126 of the knife mold 12 is vertically provided with a cutting kn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com