Apparatus for moving mould injection and hot nitrogen far infrared sulfurization of tyre

A vulcanized tire and far-infrared technology, applied in the field of rubber machinery, can solve the problems of low production efficiency, long vulcanization time, large energy consumption, etc., and achieve the effect of high production efficiency, compact structure, and overcoming glue back.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The device includes the following components,

[0026] A Install the capsule injection mold;

[0027] B. Inject rubber into the above-mentioned installed capsule injection mold one by one with a mold-shifting back-push injection molding machine;

[0028] C uses the far-infrared heating capsule vulcanization tank to centrally vulcanize the capsule injection mold after the injected rubber.

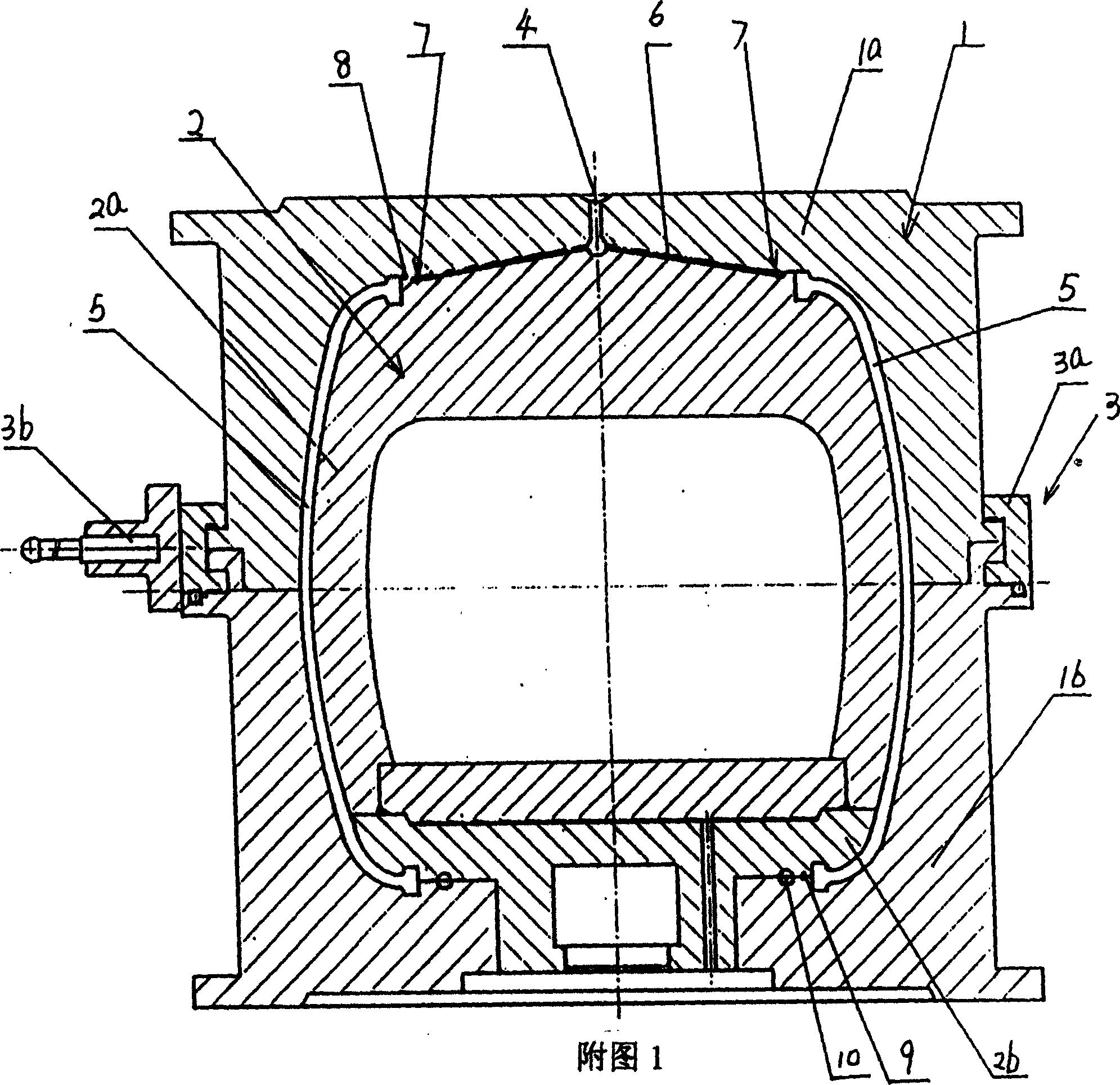

[0029] As shown in accompanying drawing 1, the capsule injection mold includes an outer mold 1 and a core mold 2, wherein the outer mold 1 is divided into an outer upper mold 1a and an outer lower mold 1b, and the core mold 2 is also divided into an upper core mold 2a and a lower core Die 2b; the clamping device 3 that clamps the entire mold is the clamping ring 3a of the outer upper mold 1a and the outer lower mold 1b and the clamping handle 3b that installs the clamping ring 3a. After the vacuum-free capsule injection mold is closed, the end of the capsule chamber 5 communicates w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com