Combed cotton and tencel fiber blended 60S babysbreath figured cloth and weaving process thereof

A technology of Tencel fiber and Gypsophila extraction, which is applied in the field of combed cotton Tencel fiber blended 60S Gypsophila jacquard fabric and its weaving process, can solve the problems of low output, low loom efficiency, etc., and achieves high warp density. , The effect of reducing jumping defects and eliminating reed marks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

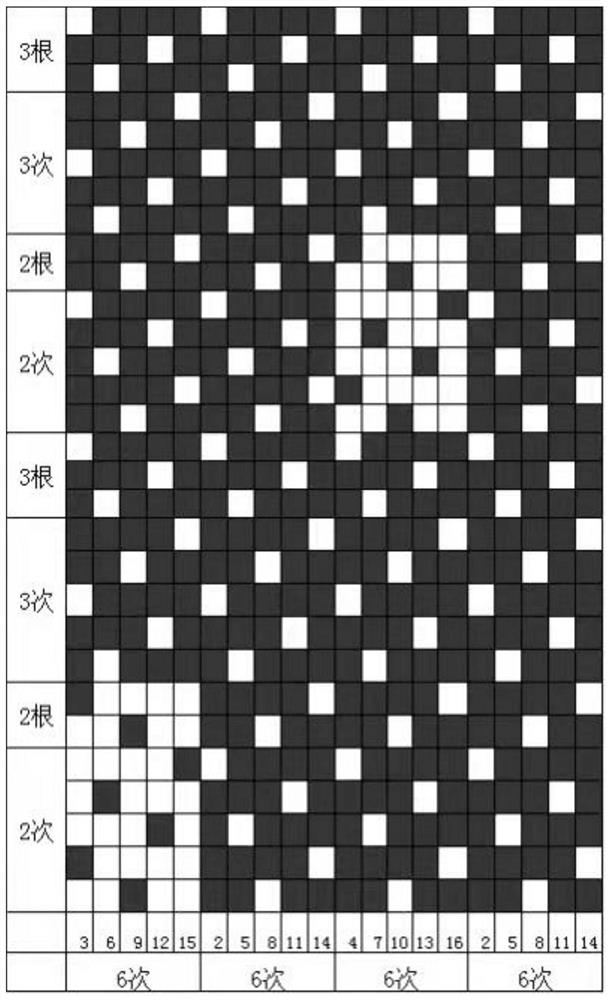

[0032] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0033] Combed cotton and tencel fiber blended 60S baby's breath jacquard fabric, the fabric includes two fibers of cotton and tencel, the warp of the fabric is JC / Ten(70 / 30)60S, and the weft is triple JC / Ten(70 / 30) 60S, the warp and weft density is 787 / 251.5×3 / 10cm, and the cloth width is 310cm; among them: J stands for "combed", C stands for "cotton", Ten stands for "tencel", 70 / 30 stands for "two fibers The blending ratio is 70:30", "S" stands for branch.

[0034] Combed cotton / tencel fiber blended 60S baby's breath jacquard fabric, the processing procedure is as follows:

[0035] (1) Warping process: Use the CGGA114B batch warping machine to draw the JC / Ten (70 / 30) 60S warp yarn from the original cheese, and evenly form a piece of yarn, so th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com