Forced separation centrifugal pressure plate

A centrifugal, pressure plate technology, used in clutches, automatic clutches, mechanical equipment, etc., can solve the problems of difficult shifting, inappropriate use of variable speed transmission systems, inability to transmit loads, etc. Affect and solve the effect of difficult shifting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

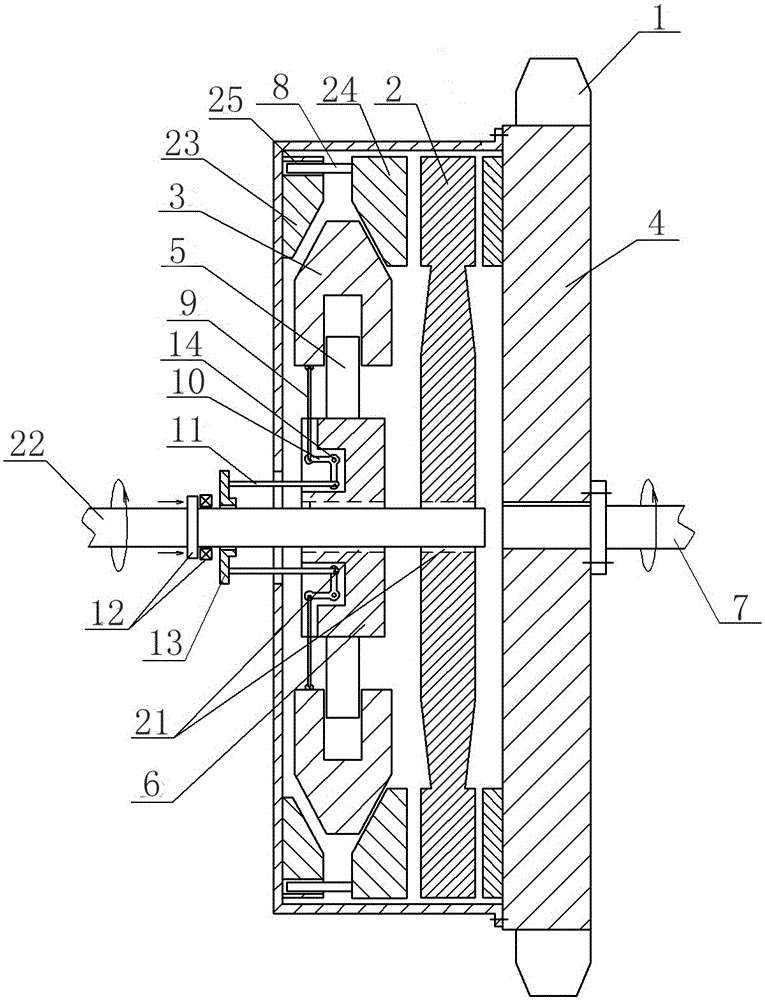

Embodiment 1

[0020] Embodiment 1: see figure 1 , the first forced separation centrifugal clutch, including the driving part 6, the centrifugal body 3 and the driven part 4. The rotating shaft 22 of the driving part is connected to the rotating shaft of the engine, and the driven part 4 is connected to the load through transmission. The driven part can be connected to the load directly or through a mechanism such as a pulley. figure 1 The load in is the flywheel 1 integrated with the follower 4. Centrifugal body 3 is frictionally matched with the inner cavity of follower 4, and an annular groove is set in the inner cavity of follower 4, and a conical structure matching the annular groove is set on the edge of centrifugal body 3, and a wear-resistant layer is fixed on the conical structure . A radial guide structure is set between the centrifugal body 3 and the active part 6, the specific structure is as follows figure 1 As mentioned above, a radial radial guide rod 5 is provided on the a...

Embodiment 2

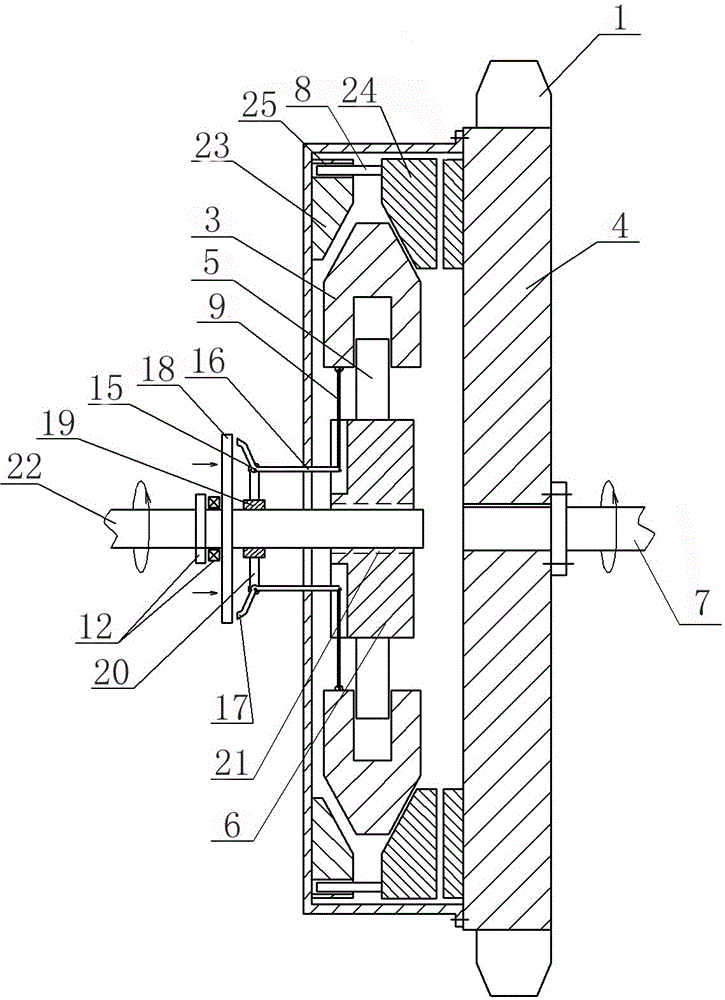

[0022] Example 2: see figure 2 : The second forced separation centrifugal clutch includes a driving part 6, a centrifugal body 3 and a driven part 4. The rotating shaft 22 of the driving part is connected to the rotating shaft of the engine, and the driven part 4 is connected to the load through transmission. The driven part 4 can be connected to the load directly or through mechanisms such as pulleys. figure 2 The load in is the flywheel 1 integrated with the follower 4. Centrifugal body 3 is frictionally matched with the inner cavity of follower 4, and an annular groove is set in the inner cavity of follower 4, and a conical structure matching the annular groove is set on the edge of centrifugal body 3, and a wear-resistant layer is fixed on the conical structure . A radial guide structure is set between the centrifugal body 3 and the active part 6, the specific structure is as follows figure 1 As mentioned above, a radial radial guide rod 5 is provided on the active me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com