Air conveying type spiral feeding system

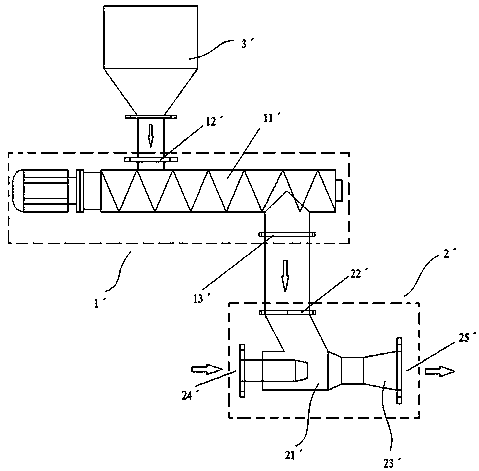

A screw-feeding and air-feeding technology, applied in conveyors, mechanical conveyors, transportation and packaging, etc., can solve problems such as performance, power consumption mismatch, no anti-bridging device, easy to stick to the wall, etc., to reduce idling No feeding or insufficient feeding, overcoming long-distance transportation, and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

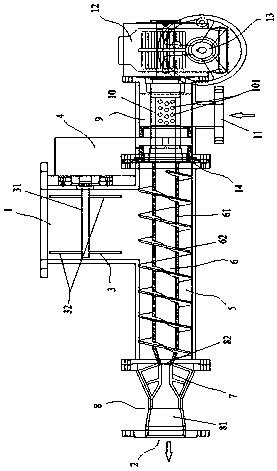

[0020] Such as figure 2 As shown, an air-driven screw feeding system includes a material inlet 1, a material outlet 2, an anti-bypass device 3, a transmission box 4, a mixing chamber 5, a screw conveyor 6, a reamer 7, an ejector 8, an air inlet Chamber 9, ventilation pipe 10, air inlet 11, reducer 12 and motor 13; one end of mixing chamber 5 is connected to injector 8, and the other end is connected to air inlet chamber 9, and the air inlet chamber 9 communicates with air inlet 11, and the injection The nozzle 81 of the device 8 communicates with the material outlet 2, the air inlet chamber 9, the mixing chamber 5 and the injector 8 are all sealed and separated, the upper end of the material inlet 1 is provided with an anti-bridging device 3, and the material inlet 1 is connected to the mixing chamber. 5, the mixing chamber 5 is provided with a screw conveyor 6, the screw conveyor 6 includes a spiral tube 61 and a spiral sheet 62 wound on the outer wall of the spiral tube 61,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com