Automobile vibration energy recovery system and control method

A vibration energy recovery, automobile technology, applied in the control device, auxiliary drive device, etc., can solve the problems of energy difficulty, dispersion, and braking energy concentration, etc., to expand the vibration energy range, ensure ride comfort, and improve recovery efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

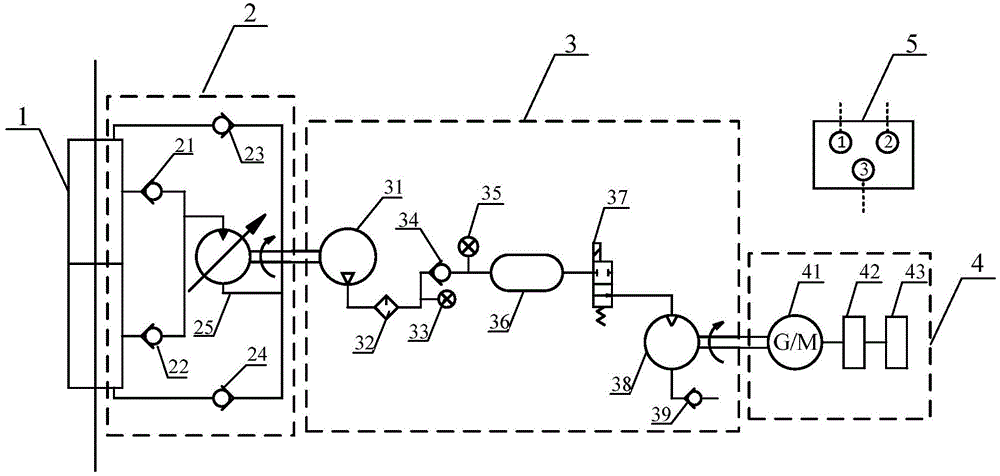

[0039] The vehicle vibration energy recovery system and control method mainly include a suspension system, a hydraulic actuator 2, a pneumatic actuator 3, electrical equipment 4 and a controller 5;

[0040] Wherein, suspension system refers to the suspension system with hydraulic shock absorber 1;

[0041] The hydraulic actuator 2 includes a one-way valve a21, one-way valve b22, one-way valve c23, one-way valve d24 and hydraulic motor 25;

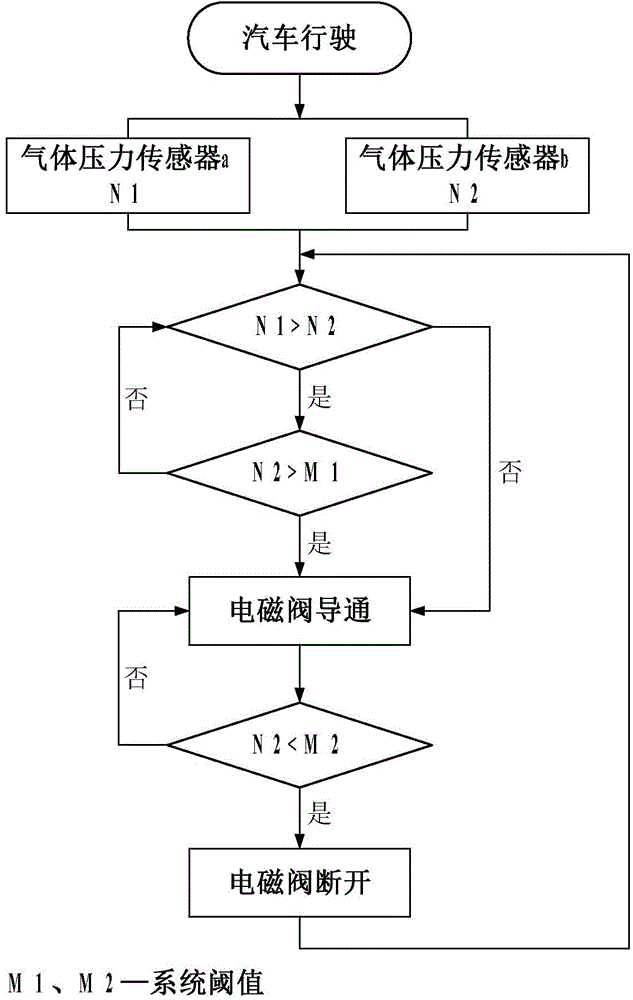

[0042] The pneumatic actuator 3 includes an air compressor 31, an air dryer 32, a gas pressure sensor a33, a gas pressure sensor b35, a one-way valve e34, an air storage tank 36, a two-position two-way solenoid valve 37 and an air motor 38;

[0043] The electrical equipment 4 includes a generator 41, a storage battery 42 and a vehicle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com