Mulberry silk fiber oil removing and adhesive preserving process

A mulberry silk fiber and process technology, which is applied in the field of mulberry silk fiber production technology, can solve the problems of low sericin content, affecting service life, and insufficient silk fiber tension, so as to improve product quality and grade, improve overall efficiency, and save energy. Effect

Active Publication Date: 2015-05-13

HENAN MINXING COCOON SILK

View PDF7 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In the silk spinning raw material products, too much sericin content will affect the luster of the silk, and the silk fiber is easy to harden and turn ye

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

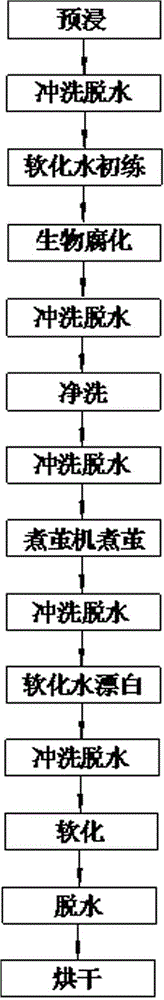

The invention provides a mulberry silk fiber oil removing and adhesive preserving process. The process is characterized by comprising the steps of presoaking, washing and dehydrating, softened water primary scouring, biological degenerating, washing and dehydrating, detergent washing, washing and dehydrating, cocoon cooking through a cocoon cooking machine, washing and dehydrating, softened water blanching, washing and dehydrating, softening, dehydrating and drying. By means of the process, the key technical problems of difficult decoloring, oil removing and adhesive preserving in scouring mulberry silkworm silk spinning raw materials in China are solved, the blank of processing the mulberry silkworm silk spinning raw materials at home is filled, more importantly, the problem of overstocking and sluggish sales of lots of silk spinning raw materials is solved, the utilization rate of mulberry silkworm defective cocoons, spun strips and frigons is increased, product quality and grade are improved, energy is saved, energy consumption is reduced, and the overall benefit of the sericulture is increased.

Description

technical field [0001] The invention relates to a manufacturing process of mulberry silk fiber, in particular to a process of removing oil and preserving glue of mulberry silk fiber. Background technique [0002] Silk is composed of two silk fibroin wrapped around sericin, the weight of sericin accounts for about 25%, and the weight of silk fibroin accounts for about 75%. The pigment plays a protective role and a role in bonding silk fibers. Sericin is water-soluble and easily soluble in hot water, acid, and alkali solutions, while silk fibroin can only partially swell but not dissolve in water. In silk products, many years of printing and dyeing practice and clothing wearing have proved that if the sericin content exceeds 5%, it will affect the luster of the silk. Silk products are easy to decolorize and become yellow. Brittle and easy to break, seriously affecting the service life of the product. The oil content of silk fiber exceeds 0.5%, the spinnability is poor, ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): D01B7/00D01C3/00

CPCD01C3/00

Inventor 卢福堂王志强王迎旺魏会丽卢瑶林蕊

Owner HENAN MINXING COCOON SILK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com