Concrete box beam first-aid repair method with prefabricated part on-site assembling combination beam

A technology of concrete box girder and prefabricated components, which is used in bridge maintenance, erection/assembly of bridges, bridges, etc., to achieve the effect of quickly restoring traffic line operations, speeding up repairs, and reducing area and scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

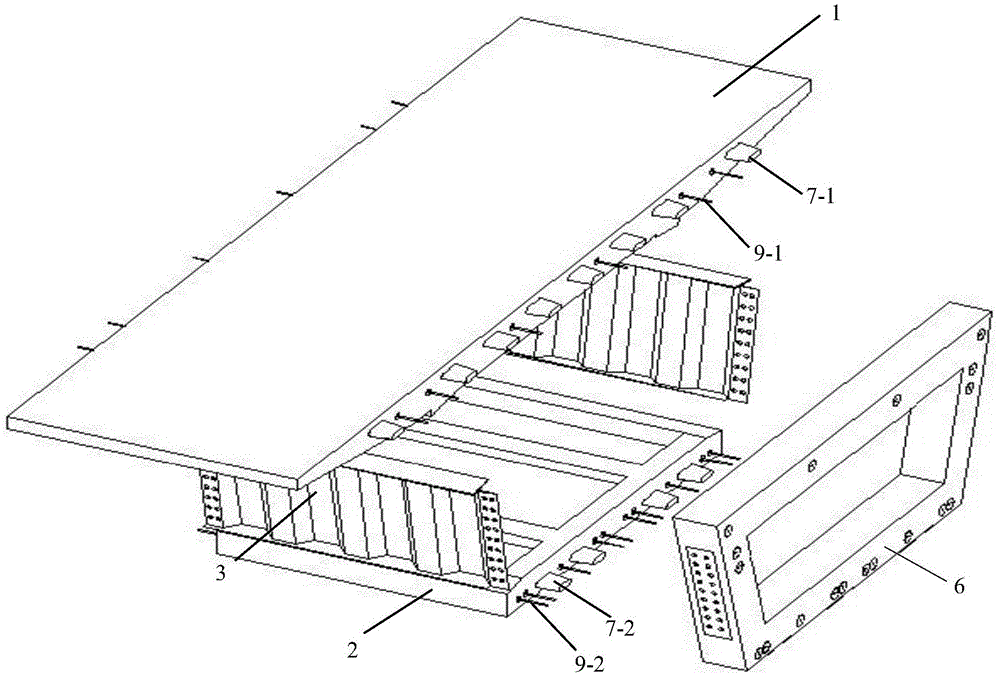

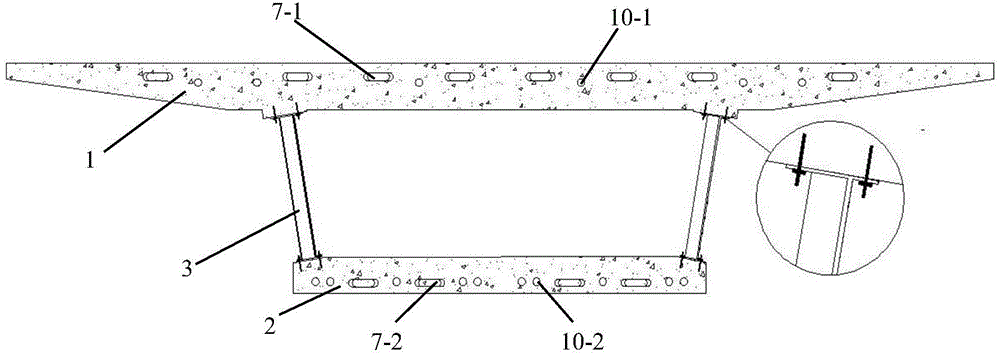

[0043] Example 1 A double-track monolithic prestressed concrete high-speed railway box girder with a span of 24 meters suffered man-made damage. For this reason, the emergency repair method of concrete box girder prefabricated and assembled by sub-components is used for emergency repair. The repair method is:

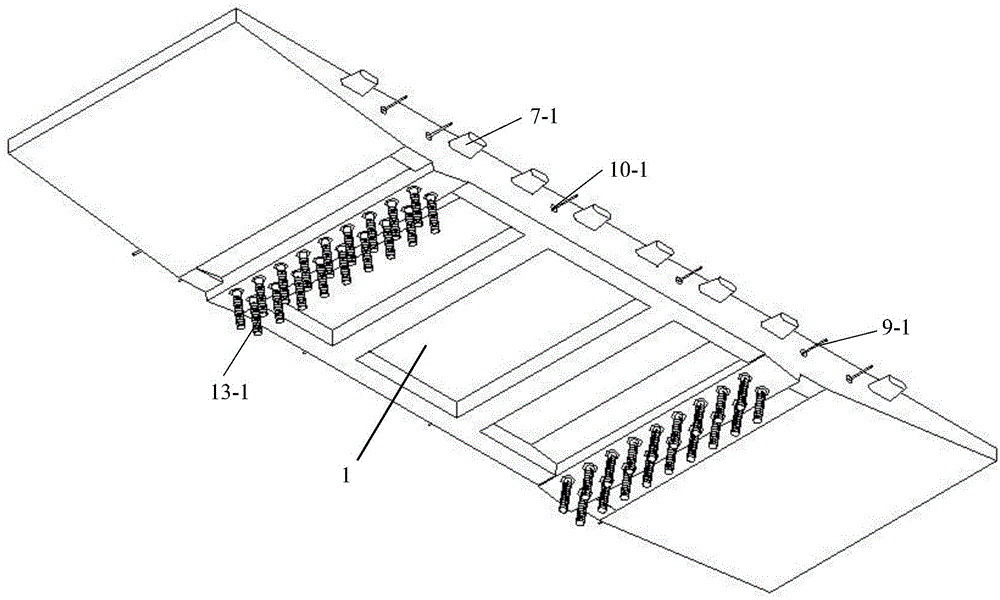

[0044] Step 1: Prefabricate concrete roof 1, concrete bottom 2, corrugated steel web 3, plug 6 and other components according to a certain size and specification and store them in the beam storage yard.

[0045] Step 2: Remove the damaged concrete box girder, and erect support 5 between two bridge piers on site.

[0046] Step 3: Go to the beam storage yard and transport the prefabricated concrete roof 1, concrete floor 2, corrugated steel web 3, plug 6 and other components of corresponding sizes and specifications to the emergency repair site.

[0047] Step 4: Hoist the concrete base plate 2 onto the erected support 5, and connect the concrete base plate 2 sections th...

example 2

[0052] Example 2 A double-track integral prestressed concrete heavy-duty railway box girder with a span of 32 meters suffered severe damage to the upper structure during the earthquake. For this reason, the emergency repair method of concrete box girder prefabricated and assembled by sub-components is used for emergency repair. The repair method is:

[0053] Step 1: Prefabricate concrete roof 1, concrete bottom 2, corrugated steel web 3, plug 6 and other components according to a certain size and specification and store them in the beam storage yard.

[0054] Step 2: Remove the damaged concrete box girder, and erect support 5 between two bridge piers on site.

[0055] Step 3: Go to the beam storage yard and transport the prefabricated concrete roof 1, concrete floor 2, corrugated steel web 3, plug 6 and other components of corresponding sizes and specifications to the emergency repair site.

[0056] Step 4: Hoist the concrete base plate 2 onto the erected support 5, and conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com