A municipal pipeline maintenance device

A municipal pipeline and bottom shell technology, applied in water supply installations, sewer pipeline systems, waterway systems, etc., can solve the problems of PVC pipeline leakage, long maintenance time, cracking, etc., and achieve the effect of ensuring normal use and effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

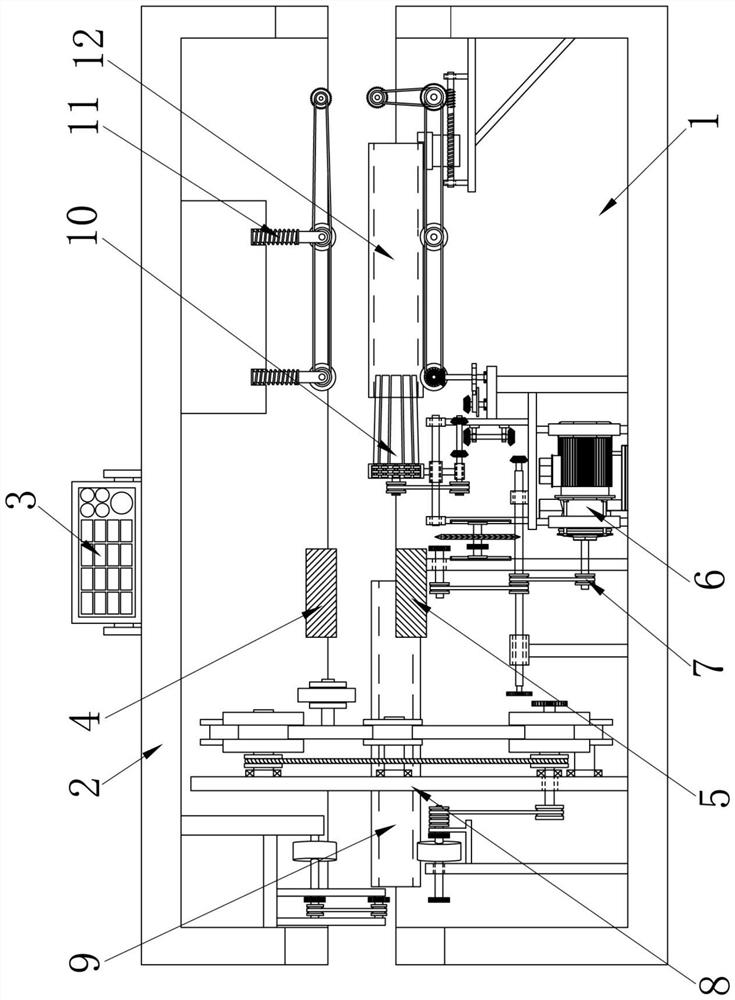

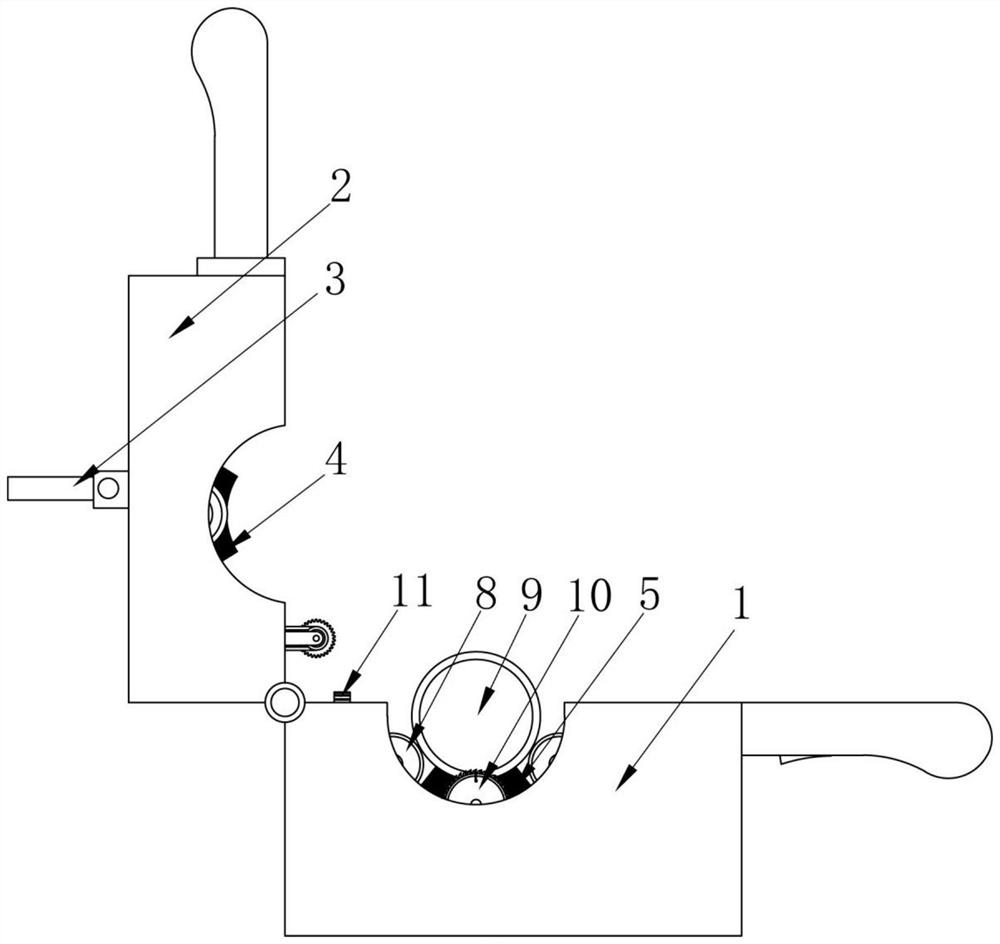

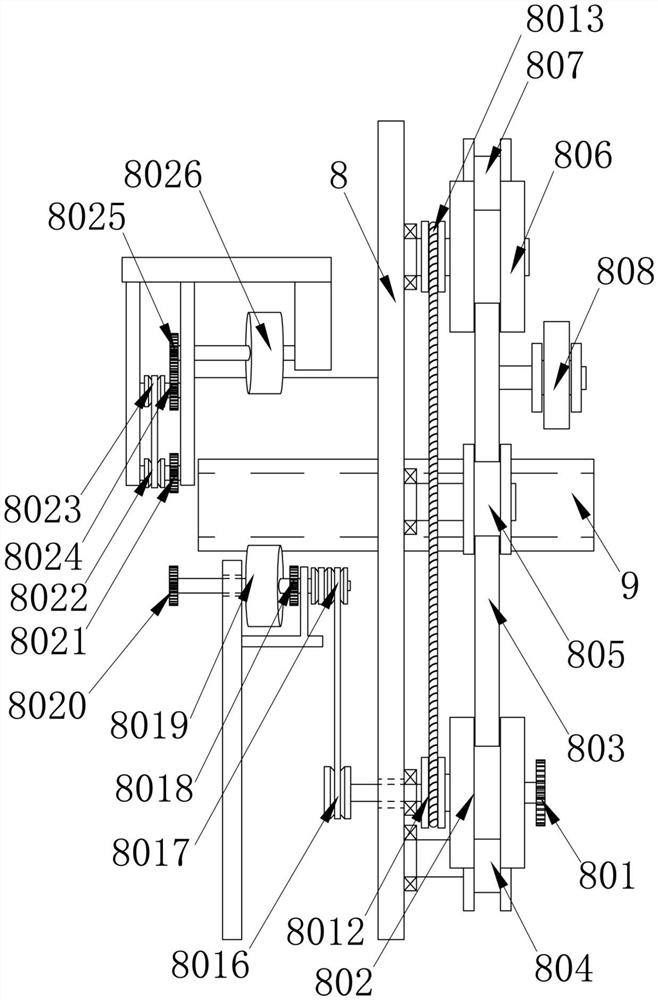

[0029] A municipal plumbing repair device such as Figure 1-10 As shown, it includes a bottom shell 1, a top shell 2, a control switch 3, a first heating ring 4, a second heating ring 5, a stepper motor 6, a first transmission wheel 7, a waterproof tape filling mechanism 8, a repair tube 9, and a plug Connected to the expansion mechanism 10, the auxiliary pipe expansion mechanism 11 and the casing 12; the rear part of the top of the bottom shell 1 is rotationally connected with the top shell 2; The middle part of the bottom end is bolted to the stepper motor 6; the bottom left part of the bottom shell 1 is provided with a waterproof tape filling mechanism 8, and the top left part of the waterproof tape filling mechanism 8 is connected to the top shell 2; There is a plug-in expansion mechanism 10; the top right part of the bottom shell 1 is provided with an auxiliary tube expansion mechanism 11, and the top end of the auxiliary tube expansion mechanism 11 is connected to the to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com