Noise reduction spring

A sound-absorbing and body technology, applied in the field of sound-absorbing springs, can solve problems such as loud noise and affect people's rest, and achieve the effects of reducing noise, simple and reasonable design, and improving user comfort.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

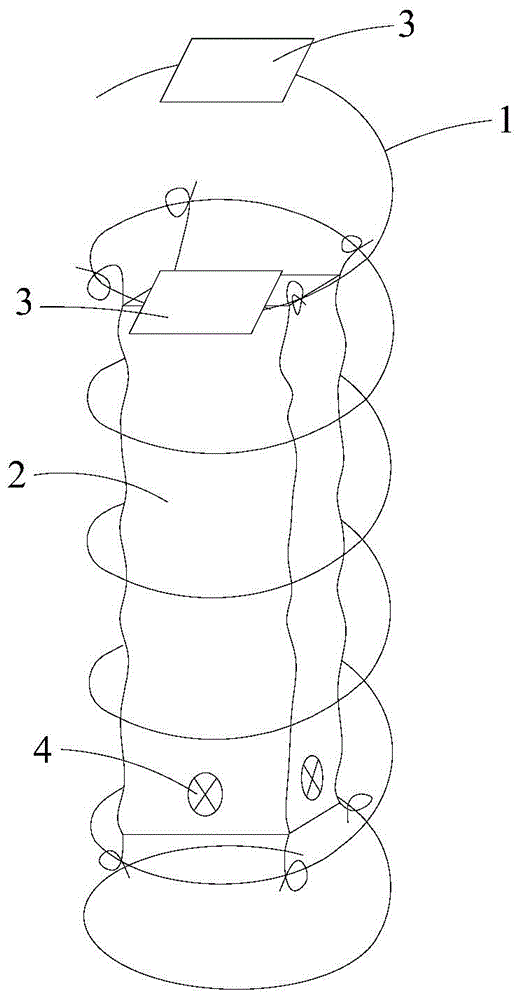

[0016] see figure 1 , a sound-absorbing spring according to a preferred embodiment of the present invention includes a spring body 1, the spring body 1 includes several coils, and a compression bag 2 is provided inside the spring body 1, and the compression bag 2 is made of flex-resistant rubber material. The softness of the rubber is relatively high, which can adapt to more times of bending and rebounding. The two ends of the compression bag 2 are fixedly connected with the coils. The side wall of the compression bag 2 is provided with four openings 4, respectively surrounding the compression bag 2. One week, the opening 4 is in the shape of a "ten". In the original sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com