Durability detection device for handle-bar bell

A detection device and durable technology, which is applied in the direction of measuring devices, testing of mechanical components, testing of machine/structural components, etc., can solve the problem of not detecting the durability of the bell cover, not having the equipment for testing the durability of the bell cover, and being unable to understand the vehicle. Problems such as the quality of the bell cover, to achieve the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

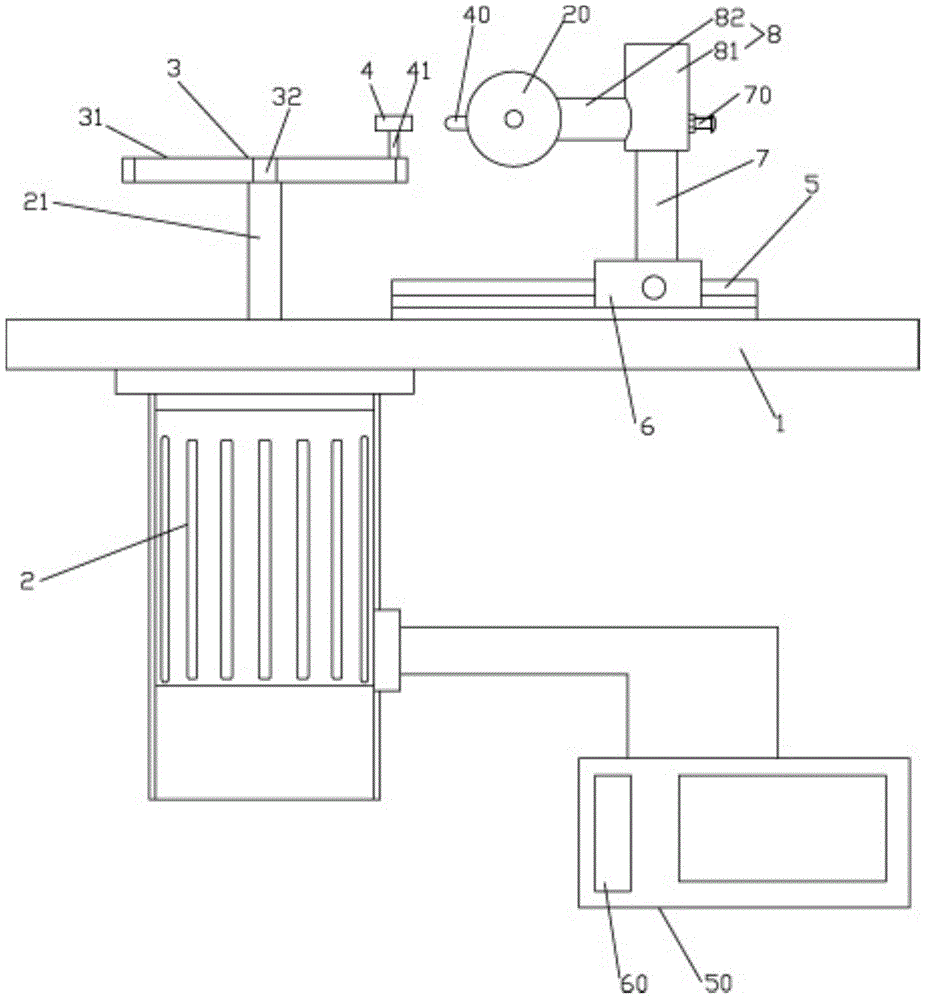

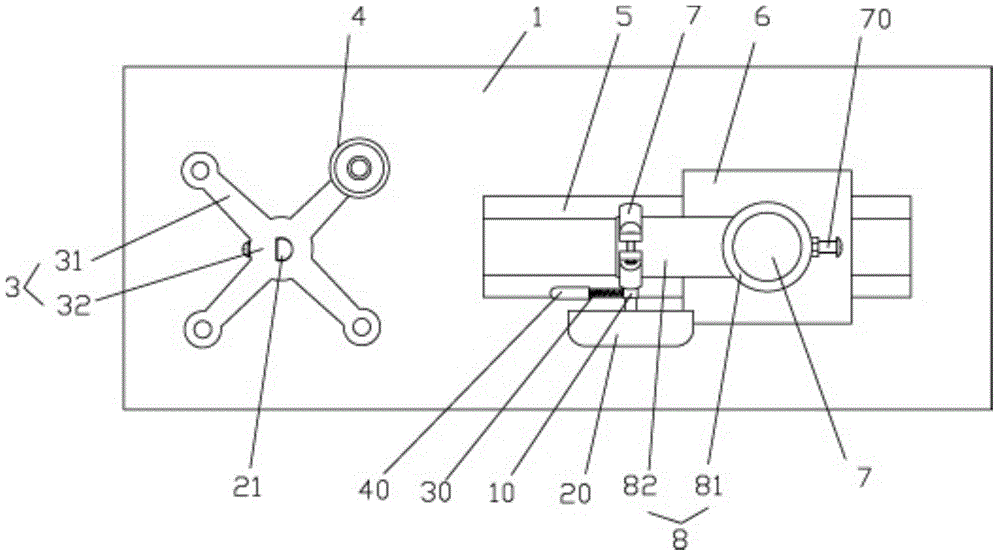

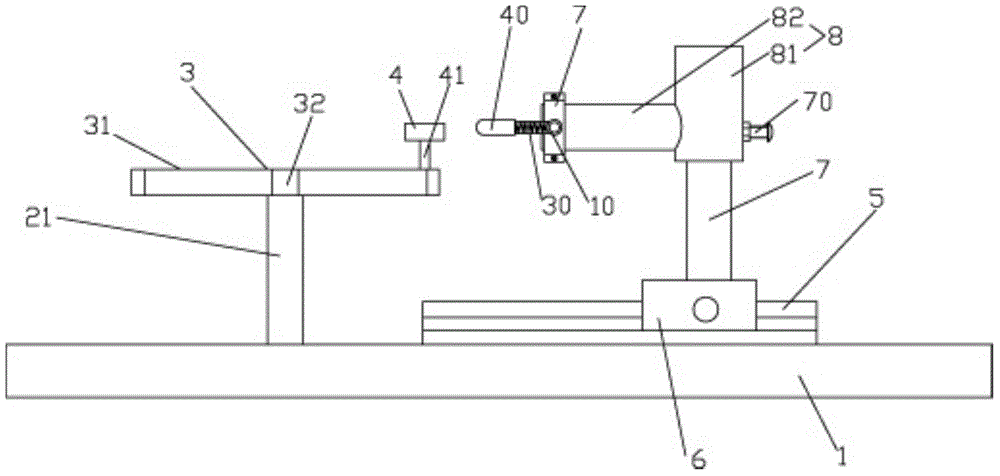

[0018] Example: see Figures 1 to 3 As shown, a vehicle bell durability testing device includes a support plate 1 and a frequency conversion motor 2, the frequency conversion motor 2 is fixed on the support plate 1, and the rotating shaft 21 of the frequency conversion motor 2 is inserted into the support plate 1 and extends out of the support plate 1. The rotating frame 3 is fixed on the top of the rotating shaft 21, and the fixed block 4 is fixed on the supporting rod 31 of the rotating frame 3; the sliding rail 5 is fixed on the supporting plate 31, and the sliding block 6 is inserted on the sliding rail 5, and the top of the sliding block 6 A fixed rod 7 is fixed, and a horizontal connecting rod 8 is fixed on the fixed rod 7. A connecting piece 9 is fixed on the top of the horizontal rod 82 of the horizontal connecting rod 8. One side of the connecting piece 9 is formed with a protrusion 10, and the bell cover 20 is screwed. Connected to the top of the protrusion 10, the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com