A cosmetic emulsifying machine

A technology for emulsifying machines and cosmetics, applied in mixers, mixer accessories, chemical instruments and methods, etc., can solve problems such as poor emulsification effect, and achieve the effects of improving quality, emulsification quality, and stirring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

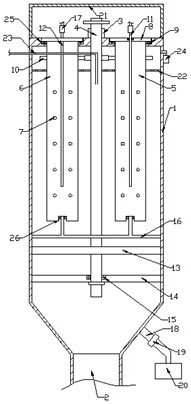

[0027] This embodiment, as the best embodiment of the present invention, discloses a cosmetic emulsifying machine, the specific structure is as follows figure 1 As shown, it includes an emulsification tank 1, the bottom of the emulsification tank 1 is provided with a discharge port 2, and the sampling port 18 is provided with a gravity check valve 19 and a collection bottle 20; the top of the emulsification tank 1 is provided with a motor 3 , the emulsifying tank 1 is provided with a rotating shaft 4 connected to the motor 3, the bottom of the rotating shaft 4 is provided with a fixed stirring paddle 13 and a movable stirring paddle 14, and the movable stirring paddle 14 is connected with the rotating shaft 4 through a rolling bearing 15; the emulsifying tank 1 The upper part is also provided with a water-phase centrifugal cylinder 5 and an oil-phase centrifugal cylinder 6, the side walls of the water-phase centrifugal cylinder 5 and the oil-phase centrifugal cylinder 6 are all...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com