Soil surface modifier and preparation method thereof

A modifier and surface layer technology, applied in the field of soil surface modifier and its preparation, can solve the problems of not having the prospect of large-scale use and promotion, increasing the cost of dust suppression covering agent and the like, and achieving the benefit of large-scale production , Excellent moisturizing type, the effect of avoiding heat accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

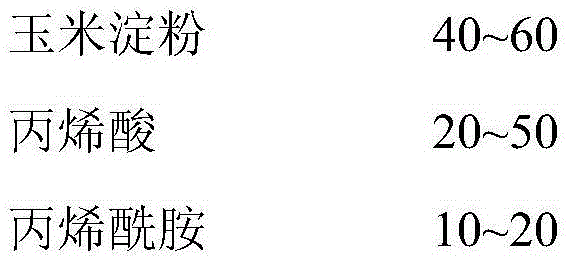

[0028] A kind of soil surface modifier, the raw material of described modifier comprises cornstarch, acrylic acid, acrylamide, initiator, linking agent and water, and the weight fraction ratio of described each raw material is:

[0029]

[0030] Further, the initiator is potassium persulfate, sodium bisulfite or a mixture of both.

[0031] Further, the crosslinking agent is sodium hydroxide, potassium hydroxide or a mixture of both.

[0032] The preparation method of the soil surface modifier comprises the following steps:

[0033] 1) Take 60%-75% of the above-mentioned cornstarch, emulsify the cornstarch at 85°C, then take the acrylic acid and acrylamide according to the above weight ratio, mix well, and wait until the temperature drops to 45°C-55°C , add the initiator and react at constant temperature for 3 hours to obtain component 1;

[0034] 2) Take the remaining corn starch, gelatinize the corn starch at 85°C, and then add the cross-linking agent to the gelatinized ...

Embodiment 2

[0041] This embodiment is an improvement made on the basis of Embodiment 1. For the same part as Embodiment 1 in this embodiment, please refer to the content disclosed in Embodiment 1 for understanding, and the content disclosed in Embodiment 1 should also be regarded as this embodiment. content, which will not be repeated here.

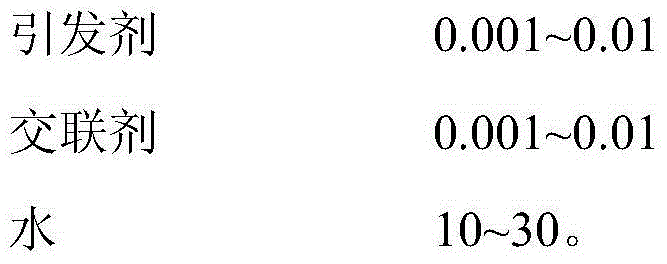

[0042] The weight fraction ratio of each raw material is:

[0043]

[0044] The preparation method of the soil surface modifier comprises the following steps:

[0045] 1) Take 65% of the above-mentioned corn starch, emulsify the corn starch at 85°C, then take the acrylic acid and acrylamide according to the above weight ratio, mix well, and when the temperature drops to 50°C, add the trigger agent, constant temperature reaction for 3 hours, to obtain component 1;

[0046] 2) Take the remaining corn starch, gelatinize the corn starch at 85°C, and then add the cross-linking agent to the gelatinized corn starch to obtain component 2;

[0047] 3) M...

Embodiment 3

[0054] This embodiment is an improvement made on the basis of Embodiment 1. For the same part as Embodiment 1 in this embodiment, please refer to the content disclosed in Embodiment 1 for understanding, and the content disclosed in Embodiment 1 should also be regarded as this embodiment. content, which will not be repeated here.

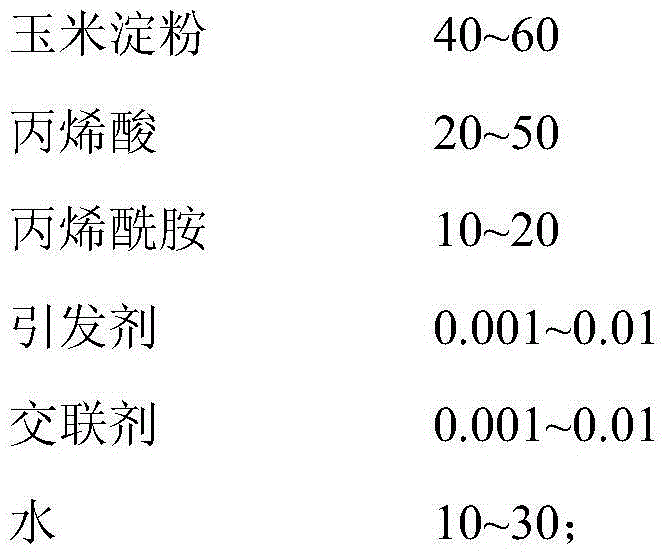

[0055] The weight fraction ratio of each raw material is:

[0056]

[0057] In order to detect the performance of the modifier, the product quality detection of the inhibitor was carried out. Test items include: appearance and sensory properties (odor, color, magazines), density, viscosity, pH value, solids, skin irritation, lightning, acute oral toxicity test, dust suppression effect (wind erosion rate, thickness of cured layer), Grafting efficiency and water absorption to distilled water, its test results are shown in Table 3:

[0058]

[0059]

[0060] In addition, heavy metal content detection (total mercury, total cadmium, total lead,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com