Processing equipment capable of improving emulsification quality of cosmetics and automatically introducing emulsifier

A kind of processing equipment and self-passing technology, applied in the direction of chemical instruments and methods, dissolving, mixing machines, etc., can solve the problems of unable to carry out regular operation, low quality of cosmetic molding, and low intelligence in the production process, so as to avoid emulsification operation , easy operation and convenient production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing:

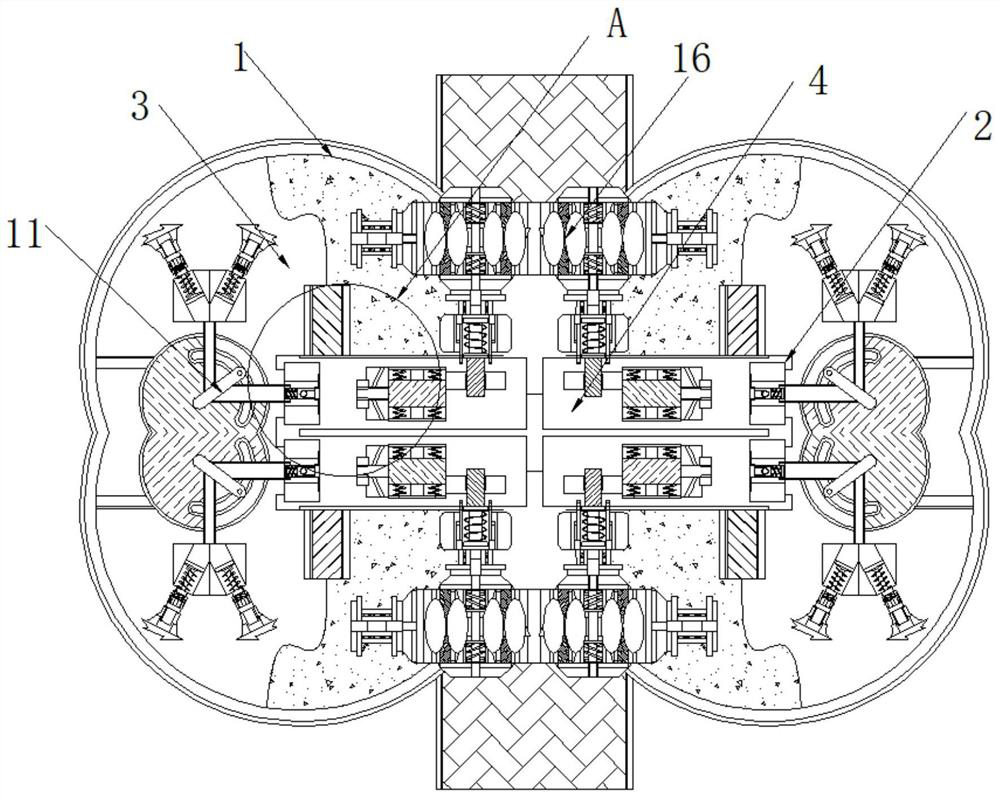

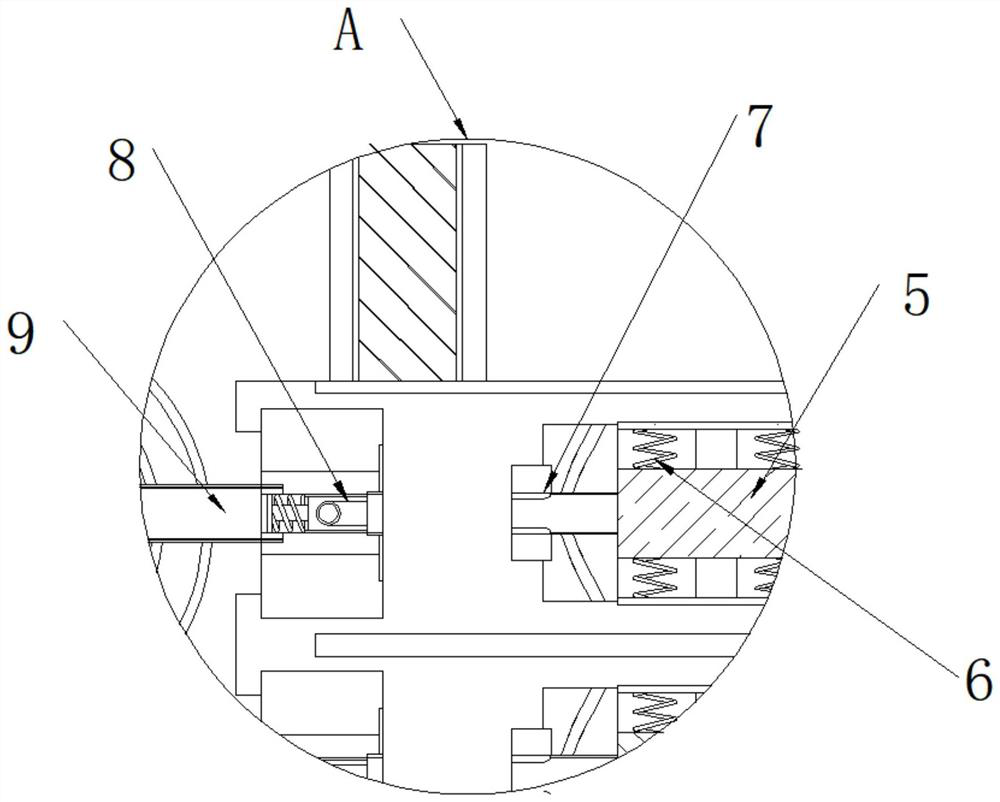

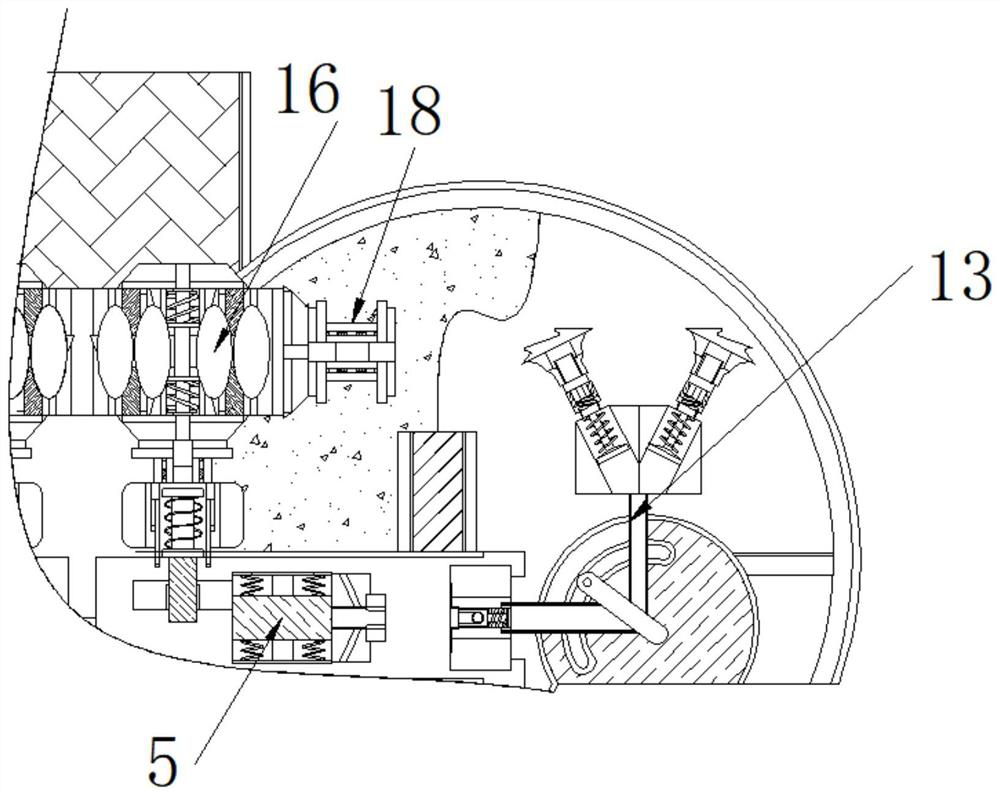

[0021] as attached figure 1 to attach Figure 5 Shown:

[0022] The present invention provides a processing equipment for improving the emulsification quality of cosmetics and self-passing emulsifier, comprising an emulsification seat 1, an emulsification tray 2 is fixedly connected to the inside of the emulsification seat 1, and a material holding tray 3 is movably connected to the outer surface of the emulsification tray 2, The interior of the emulsification disc 2 is movably connected with a sliding seat 4, the interior of the sliding seat 4 is movably connected with a flexible frame 5, the interior of the flexible frame 5 is movably connected with a telescopic spring 6, and the side surface of the flexible frame 5 is movably connected with a first magnetic plate 7 , the inside of the sliding seat 4 and the side surface away from the first magnetic plate 7 are movably ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com