Pull testing device

A testing device and a technology for lifting straps, which are used in measuring devices, testing of mechanical components, testing of machine/structural components, etc., and can solve problems such as blank quality detection of handles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

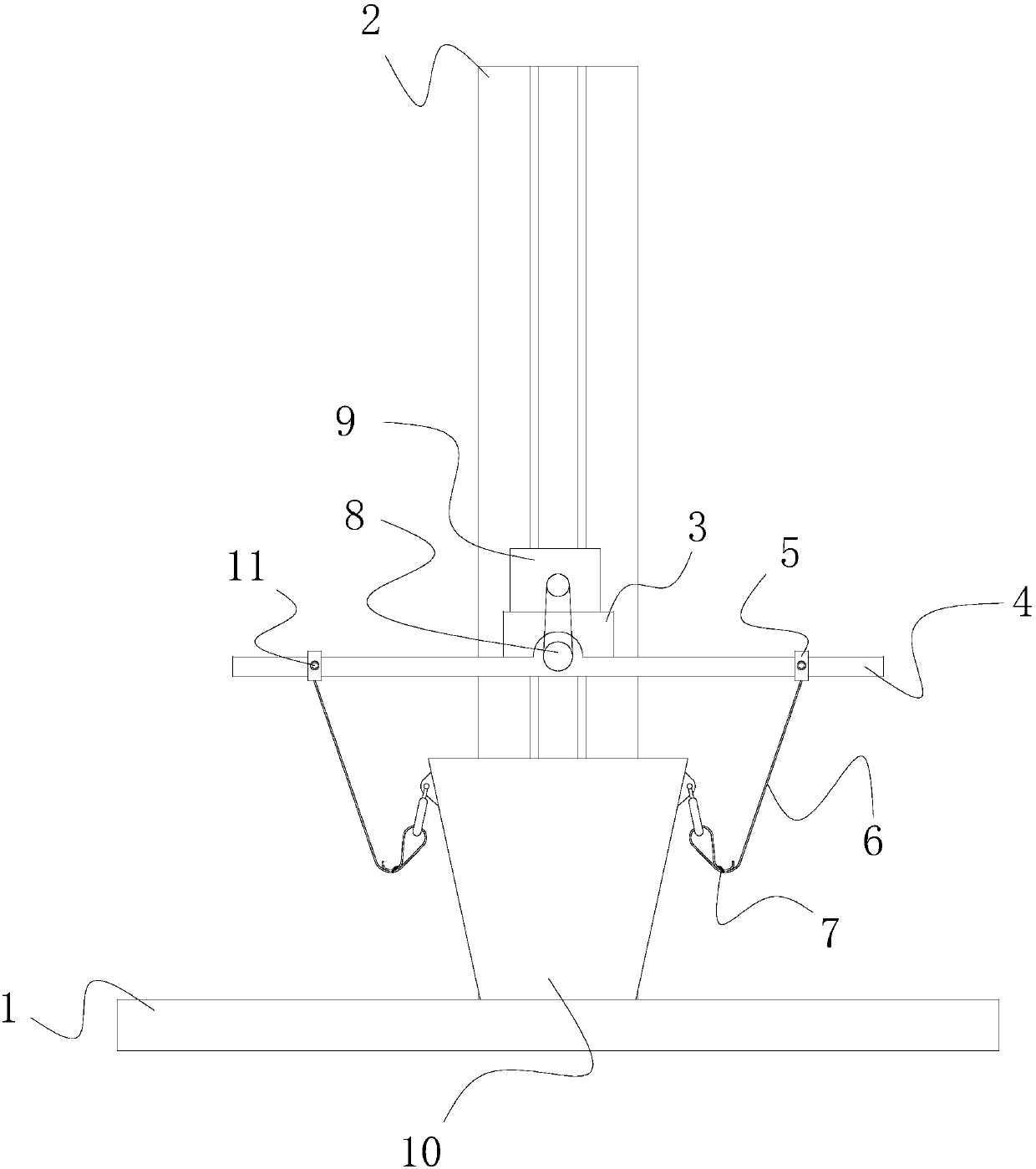

[0014] see figure 1 , a lifting test device, including a base 1, a linear module 2, a lifting base 3, a horizontal hanger 4, a cover block 5, a flexible lifting belt 6, and a buckle 7. The linear module 2 is a product that can be easily obtained in the prior art.

[0015] The bottom of the linear module 2 is fixed on the base 1, and the linear module 2 has a slider that can move up and down vertically. The lifting base 3 is fixed on the slider. The horizontal hanger 4 is fitted on the lifting base 3 . The two ends of the horizontal hanger 4 are respectively equipped with the cover block 5, the flexible lifting belt 6 is connected to the cover block 5, and the free end of the flexible lifting belt 6 is equipped with the buckle7.

[0016] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com