Detection jig

A technology for detecting fixtures and testing signals, applied in static indicators, instruments, etc., can solve problems such as panel damage, probe damage, affecting product design and production, and achieve the effect of comprehensive and accurate judgment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

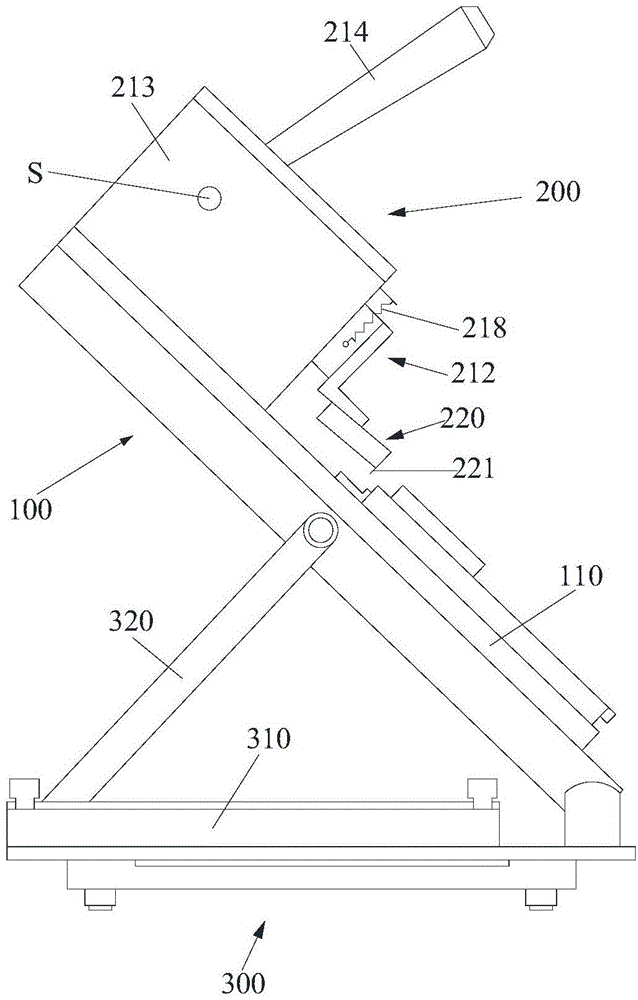

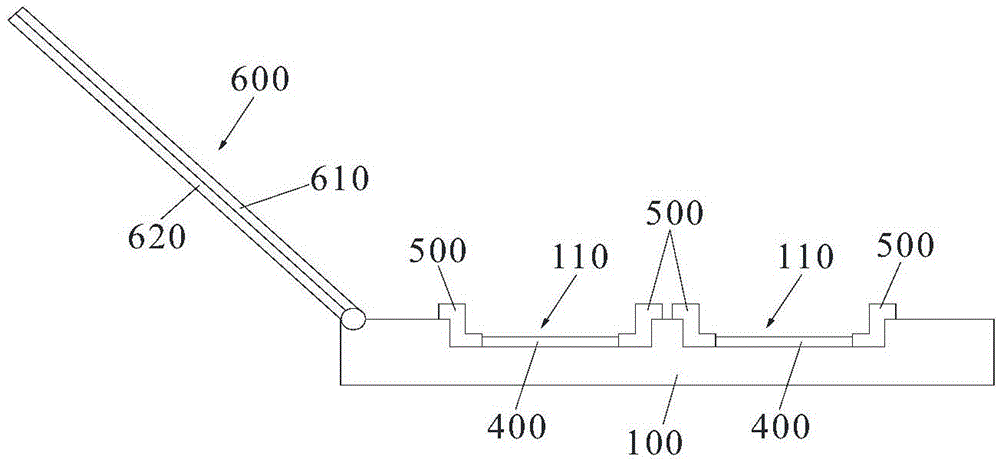

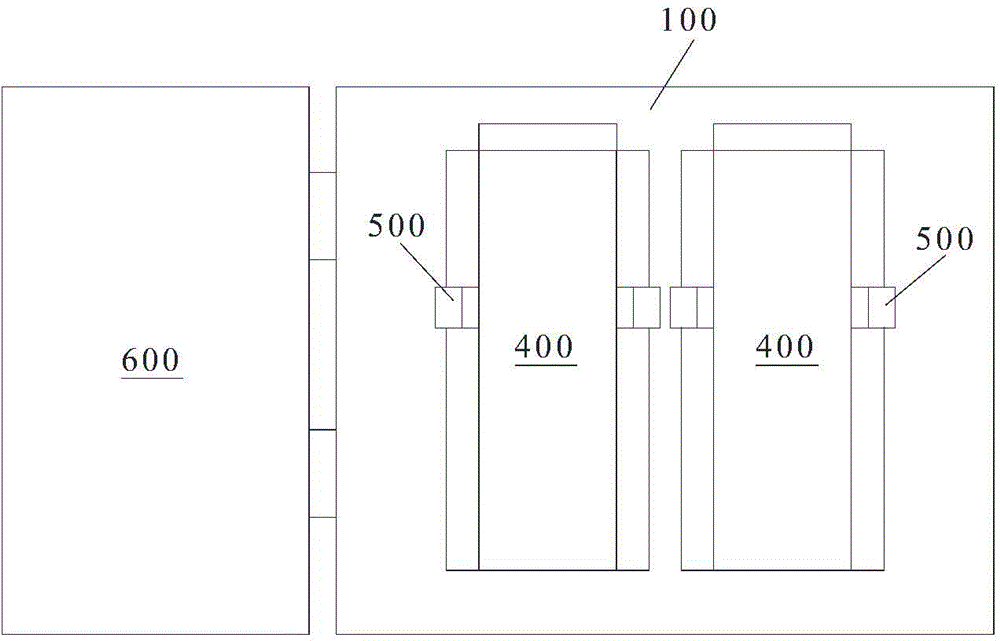

[0044] Such as Figure 1 to Figure 4 As shown in , the present invention provides a testing fixture, which includes a carrier platform 100 and a test signal output device 200, wherein the testing tool also includes a position adjustment device for adjusting the inclination angle of the carrier platform 100 Mechanism 300, the carrying platform 100 includes a plurality of carrying parts 110, each carrying part 110 is used to carry the display panel 400 to be tested placed on the carrying part 110, and the test signal output device 200 is used to respectively set on multiple A plurality of display panels 400 on the carrying part 110 provide test signals.

[0045]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com