Novel anti-drop-beam device

A new type of anti-falling beam technology, applied in bridges, bridge parts, bridge construction and other directions, can solve the problems of unsatisfactory position limit effect and poor anti-vibration effect, and achieve reliable anti-falling beams, good buffering, and improving bearing capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

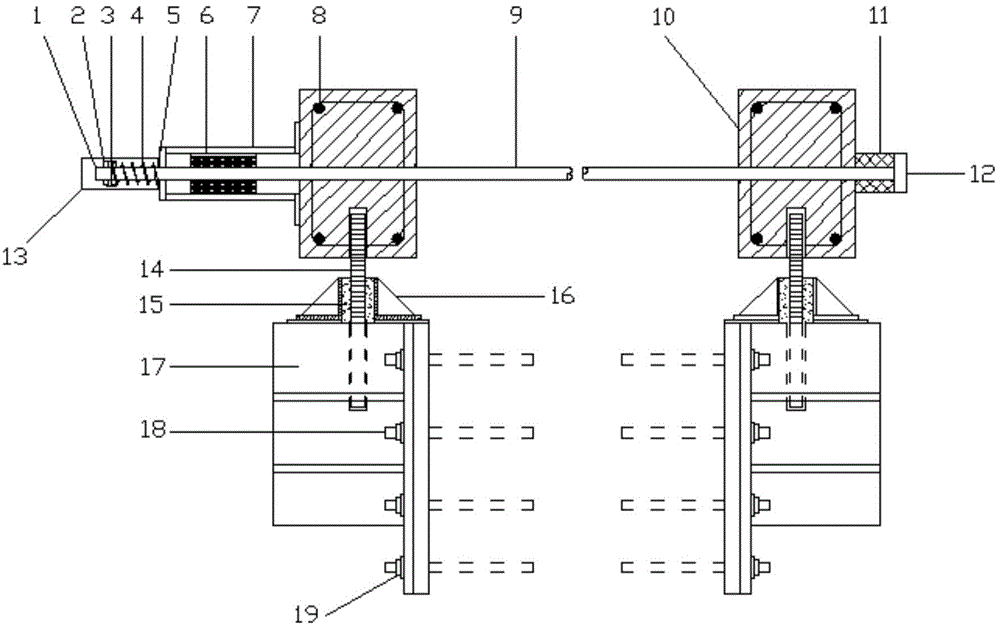

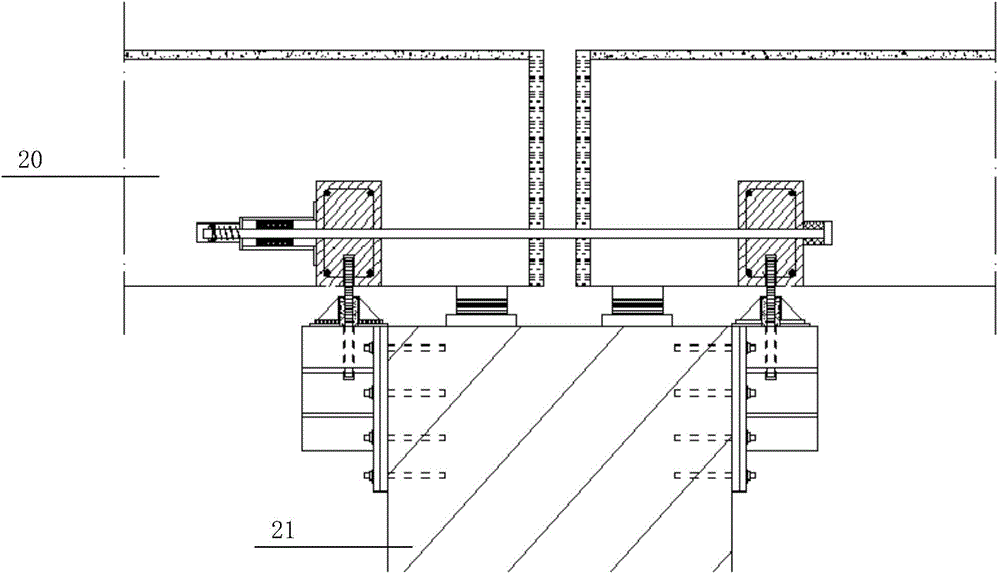

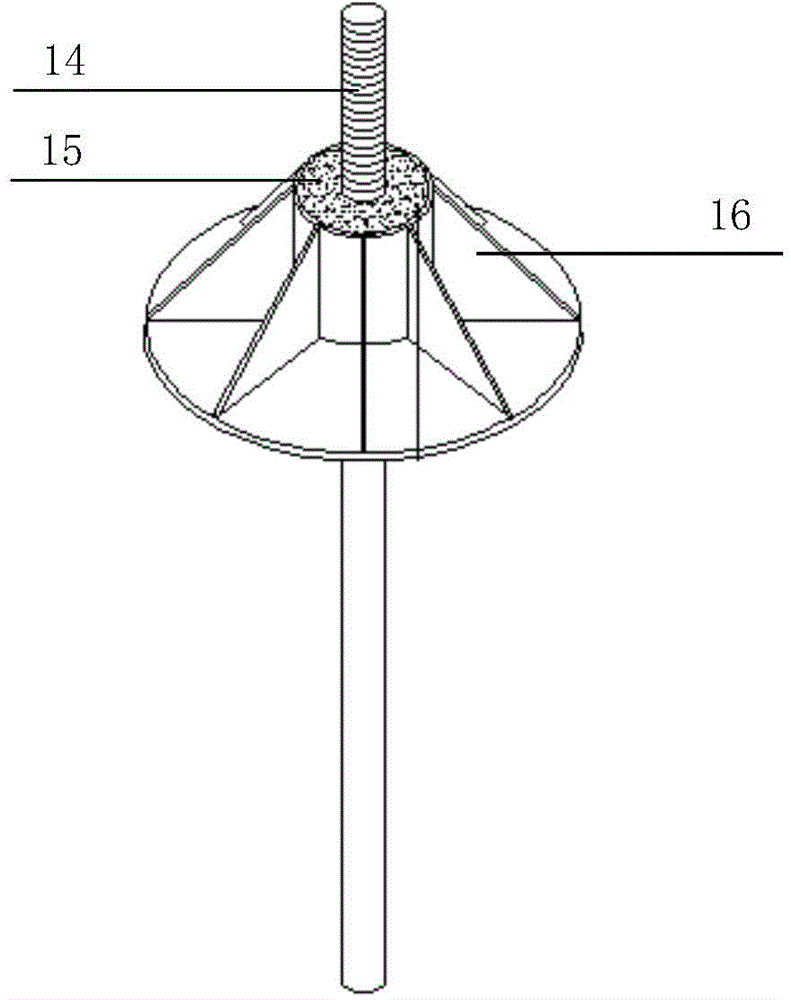

[0029] Such as Figure 1-7 A new anti-drop beam device shown includes two sections of beams 20, one end of the two sections of beams is respectively placed on the pier body 21, including a cable anti-fall beam structure and a limit anti-fall beam structure; In the anti-fall beam structure, two fixed anchor plates 10 are respectively fixed on the two sections of the beam body 20 by rivets 8, and the two fixed anchor plates are connected by a cable 9, and one end of the cable is connected to the fixed anchor plate by a high damping rubber pad 11. On the anchor plate, the rubber pad is provided with a rear cover 12, and the other end of the cable passes through another fixed anchor plate and is connected to the frictional energy dissipation device 6. A sealing cylinder 7 is arranged on the periphery of the frictional energy dissipation device 6, and one side of the sealing cylinder is connected to the frictional energy dissipation device 6. The fixed anchor plate is fixed, and a ...

Embodiment 2

[0033] Such as Figure 1-7 A new anti-drop beam device shown includes two sections of beams 20, one end of the two sections of beams is respectively placed on the pier body 21, including a cable anti-fall beam structure and a limit anti-fall beam structure; In the anti-fall beam structure, two fixed anchor plates 10 are respectively fixed on the two sections of the beam body 20 by rivets 8, and the two fixed anchor plates are connected by a cable 9, and one end of the cable is connected to the fixed anchor plate by a high damping rubber pad 11. On the anchor plate, the rubber pad is provided with a rear cover 12, and the other end of the cable passes through another fixed anchor plate and is connected to the frictional energy dissipation device 6. A sealing cylinder 7 is arranged on the periphery of the frictional energy dissipation device 6, and one side of the sealing cylinder is connected to the frictional energy dissipation device 6. The fixed anchor plate is fixed, and a ...

Embodiment 3

[0038] Such as Figure 1-7 A new anti-drop beam device shown includes two sections of beams 20, one end of the two sections of beams is respectively placed on the pier body 21, including a cable anti-fall beam structure and a limit anti-fall beam structure; In the anti-fall beam structure, two fixed anchor plates 10 are respectively fixed on the two sections of the beam body 20 by rivets 8, and the two fixed anchor plates are connected by a cable 9, and one end of the cable is connected to the fixed anchor plate by a high damping rubber pad 11. On the anchor plate, the rubber pad is provided with a rear cover 12, and the other end of the cable passes through another fixed anchor plate and is connected to the frictional energy dissipation device 6. A sealing cylinder 7 is arranged on the periphery of the frictional energy dissipation device 6, and one side of the sealing cylinder Fixed with the fixed anchor plate, the other end is provided with a buffer 5, the cable passes thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com