Double-cantilever steel damping device

A technology of steel damping and double cantilever, which is applied to bridge parts, bridges, buildings, etc., can solve the problems that the horizontal energy consumption limit function is difficult to be guaranteed, the mechanical behavior can no longer be guaranteed, and the universality of space installation is limited. , to achieve the effects of strong controllability of mechanical behavior, widening application potential, and low vertical space requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

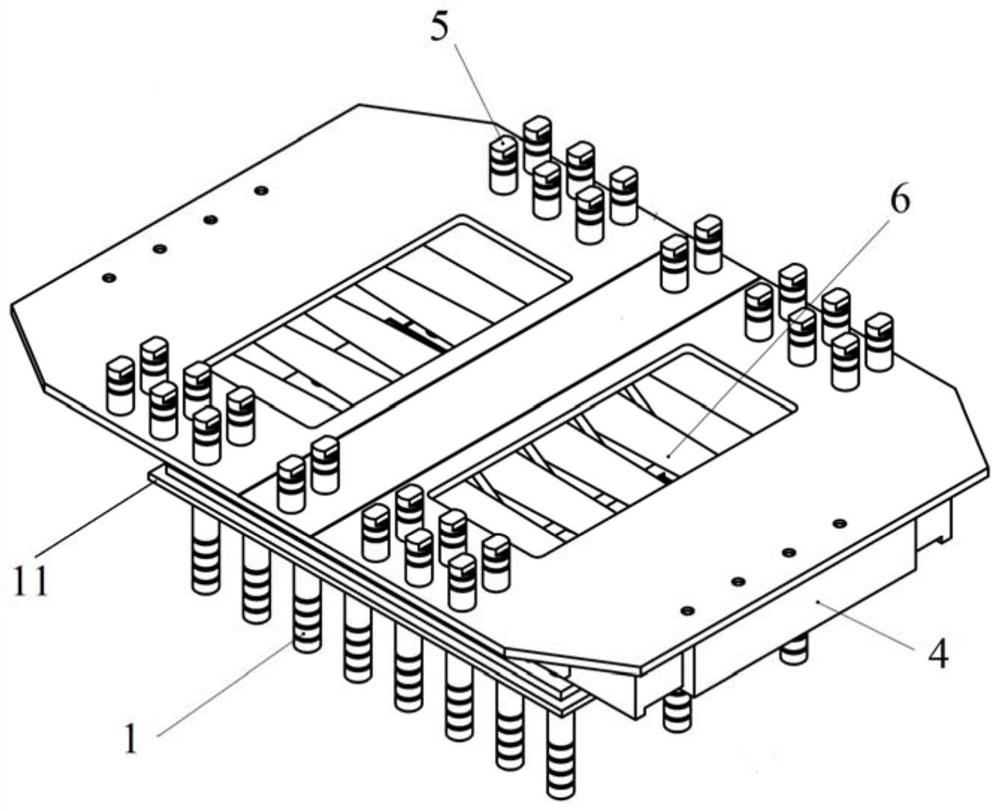

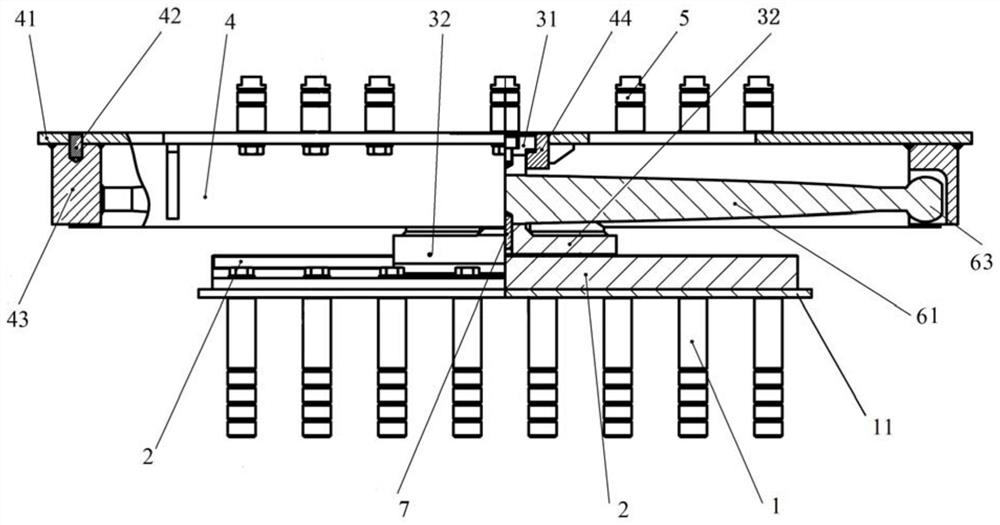

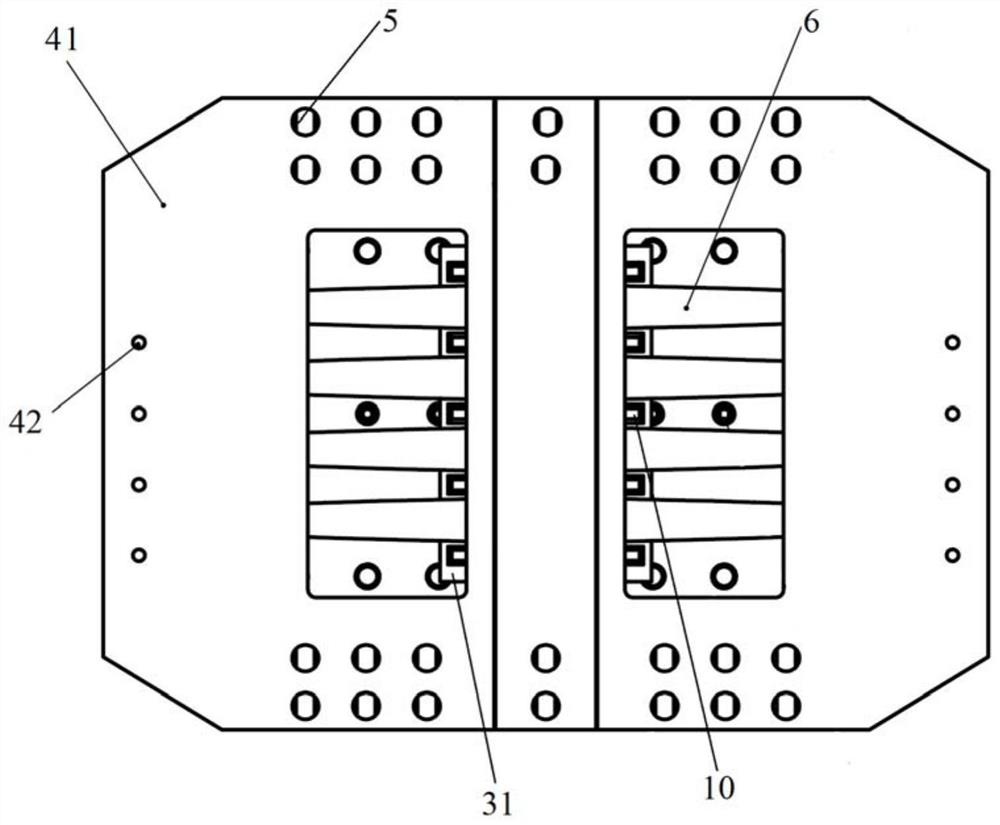

[0068] refer to Figure 1-Figure 9 , the present embodiment provides a double cantilever steel damping device, which is a vertical pull-out resistant double cantilever bar-shaped steel damping device. Including ground anchor bolt 1, base slide plate 2, guide base 3, thrust steel box 4, connecting beam bolt 5 and symmetrical double cantilever steel damping unit 6, the base slide plate 2 is connected above the bottom plate 11, and the ground anchor bolt 1 is connected to Below the bottom plate 11, the ground anchor bolt 1 is used to realize the connection between the base slide plate 2 and the base plate 11 and the top of the pier, the lower part of the guide base 3 is slidingly connected with the upper part of the base slide plate 2, and the guide base 3 and the base slide plate 2 form the second A tensile contact pair; the middle part of the symmetrical double cantilever steel damping unit 6 is connected to the guide base 3, the two ends of the symmetrical double cantilever st...

Embodiment 2

[0081] refer to Figure 10-Figure 13 , the present embodiment provides a double cantilever steel damping device, which is a vertical non-drawing-resistant double cantilever bar-shaped steel damping device.

[0082] The difference from Embodiment 1 is that the second slideway is a non-tensile contact pair, the corresponding second slideway 31 adopts a rectangular convex structure, and the second slider 44 adopts a concave shape that is suitable for the concave-convex structure of the rectangular convex structure. Chute structure.

Embodiment 3

[0084] refer to Figure 14-Figure 18 , the present embodiment provides a double cantilever steel damping device, which is a vertical pull-out resistant double cantilever diamond-shaped steel damping device.

[0085] The difference from Embodiment 1 is that in this embodiment, the symmetrical double-cantilever steel damping unit 6 is a symmetrical double-cantilever diamond-shaped steel damping unit 62, that is, the two cantilever steel bodies form a diamond-shaped steel plate, and the symmetrical double-cantilever diamond-shaped steel damping unit The cantilever end of 62 is a cylindrical structure 64, and the cylindrical structure 64 extends into the double-row thrust holes 46 provided on the thrust steel box 4. The double-row thrust holes 46 are elliptical, and the direction along the bridge is the long axis direction. Determined by the displacement stroke of the symmetrical double-cantilever diamond-shaped steel damping unit 62, along the direction of the transverse bridge i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com