PHC anchor pile head reinforcing method for static load test of offshore high-pile wharf pile foundation

A technology of static load test and high-pile wharf, which is applied in the test of foundation structure, sheet pile wall, foundation structure engineering, etc., can solve the problem that the equipment and the anchor pile cannot be connected very firmly, the field operation is difficult, and the PHC at sea cannot be achieved. The requirements of pipe pile static load test and other issues can save manpower, improve the reinforcement effect, and be easy to operate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A PHC anchor pile pile head reinforcement method for pile foundation static load test of high pile wharf on the sea, comprising the following steps:

[0031] 1) Construction preparation

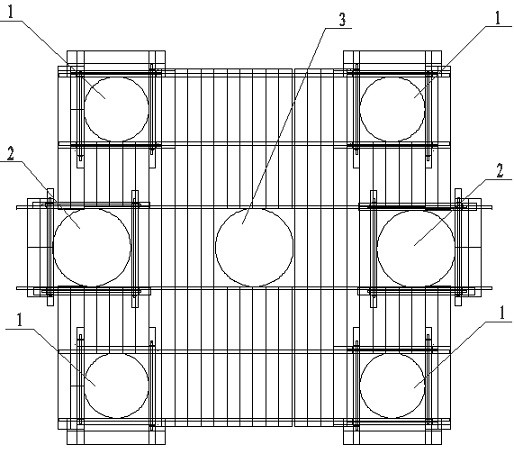

[0032] a) set up as figure 1 The construction platform shown; wherein, including PHC anchor piles 1, reference piles 2 and test piles 3, the PHC anchor piles 1 are provided with four, symmetrically arranged at four corners, and the reference piles 2 are provided with two, each The reference pile 2 is located between two PHC anchor piles 1, and one test pile 3 is arranged at the center of the four PHC anchor piles 1;

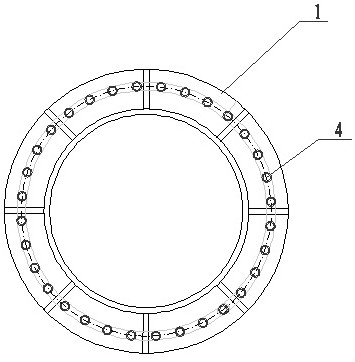

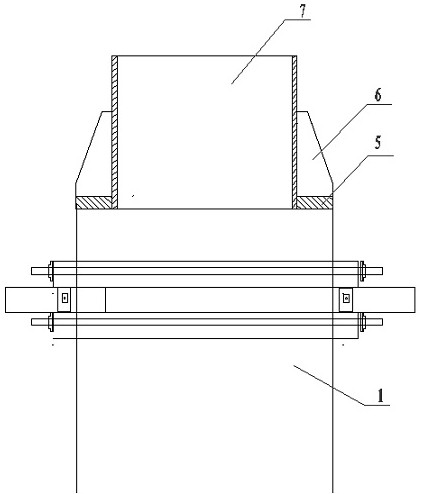

[0033] b) combine figure 2 , image 3 As shown, the steel ferrule 7 and the ferrule end plate 5 are welded, the inner diameter of the steel ferrule 7 is 740mm, the width of the rib plate 6 is 130mm, double-sided full welding is adopted, the thickness of the ferrule end plate 5 is 5cm, the sleeve 32 oval holes with a major axis of 20 mm and a minor axis of 15 mm are e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com