Positive electrode of primary lithium-manganese battery

A lithium-manganese battery and positive electrode technology, which is applied in the positive electrode field of primary lithium-manganese batteries, can solve the problems of increased labor intensity, low production efficiency, and small contact surface, and achieve the effects of reducing labor intensity, improving production efficiency, and improving firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

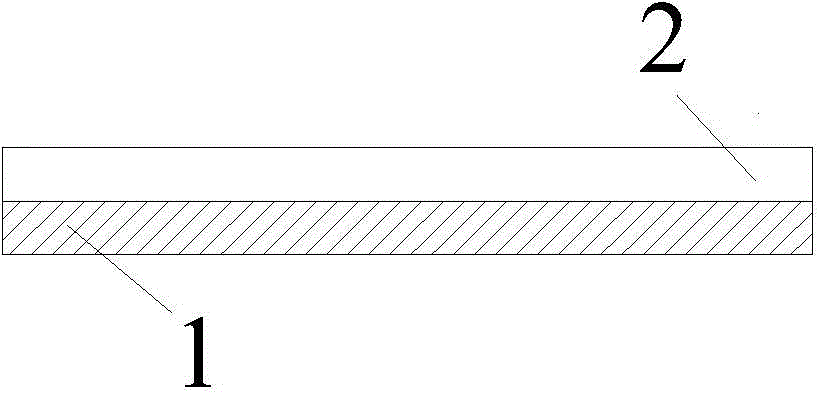

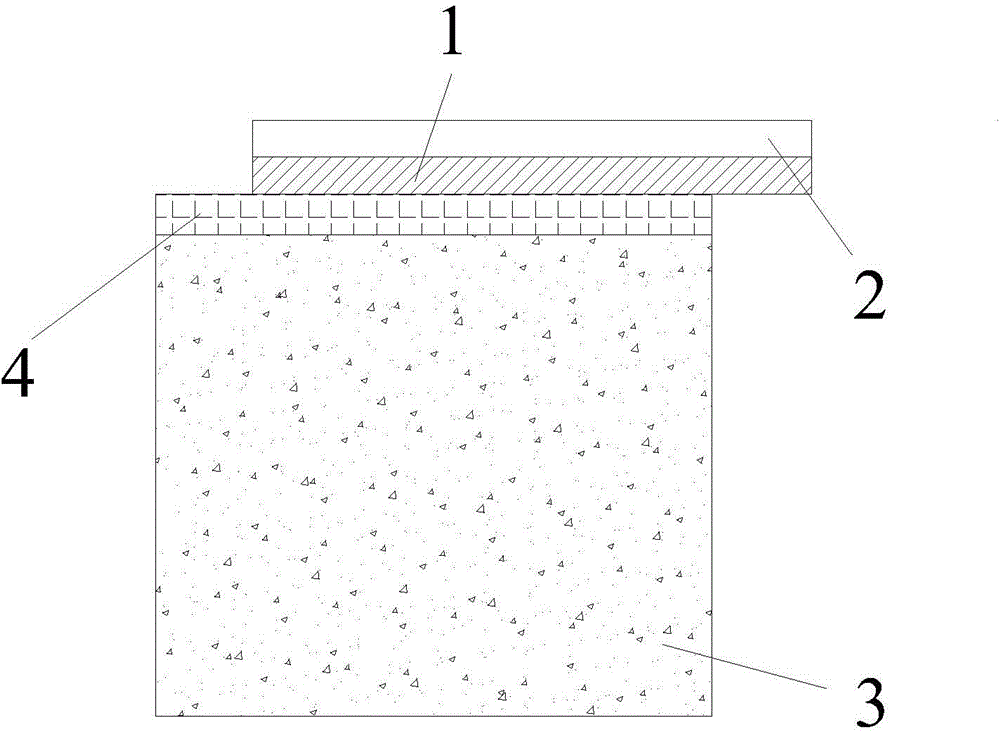

[0012] The positive electrode of the primary lithium manganese battery of this embodiment includes a positive electrode sheet and a positive electrode ear, such as figure 1 As shown, the positive lug of this embodiment is a composite tape formed by a composite of aluminum tape 1 and stainless steel tape 2, and the thickness of the composite tape is generally 0.1 to 3 mm. The aluminum strip 1 of the positive lug is in contact with the aluminum mesh 4 of the positive sheet 3 for surface-to-surface ultrasonic welding, such as figure 2 As shown, there is no need to fold the tabs in half, which simplifies the production process, avoids the phenomenon of virtual welding, and improves the firmness of welding. At the same time, there is no need for multi-point welding, which improves production efficiency and reduces labor intensity.

[0013] Place the entire roll of positive tabs with a thickness of 0.15mm on the production line equipment, with the aluminum strip down and the stainless ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap