Two-plate injection molding machine and die assembly structure thereof

An injection molding machine, two-platen technology, applied in the field of mold clamping structure of injection molding machines, can solve the problems of complex oil circuit system, not suitable for small and medium-sized two-platen injection molding machines, increase costs, etc., and achieve the effect of simple precision adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The preferred embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

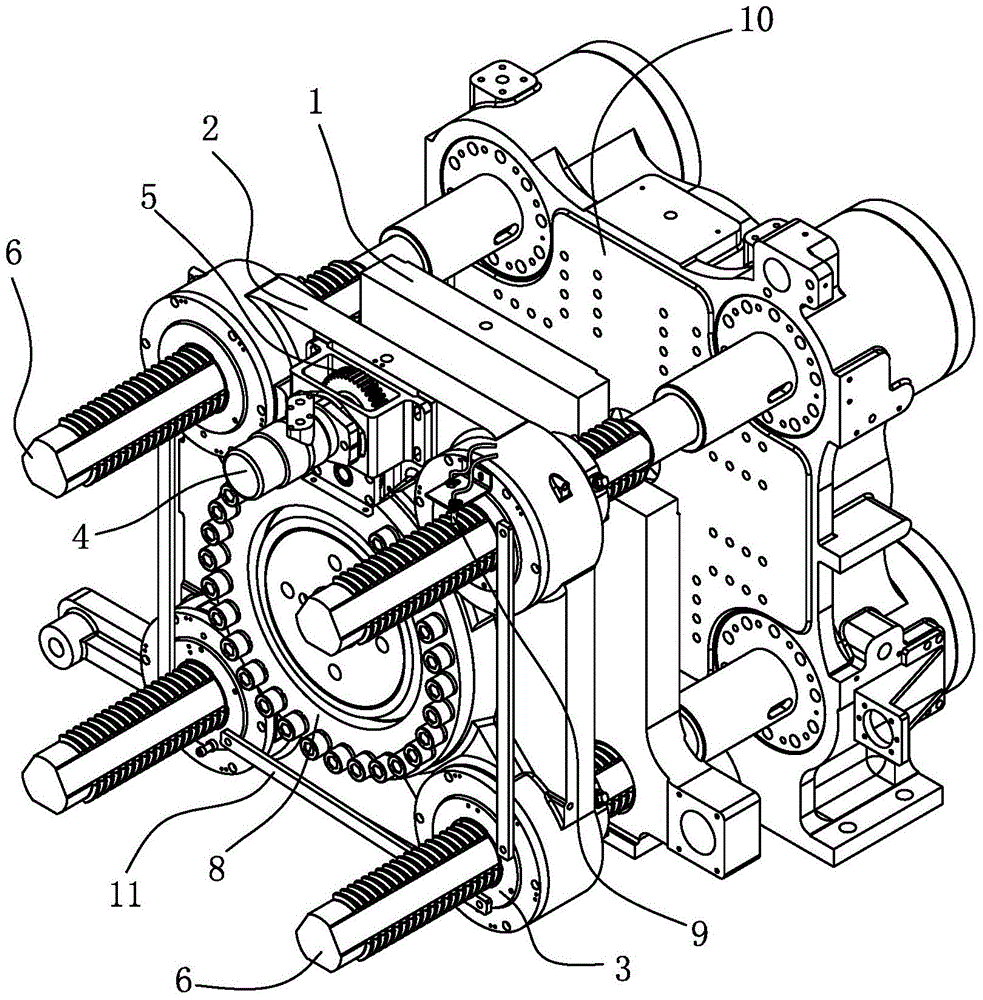

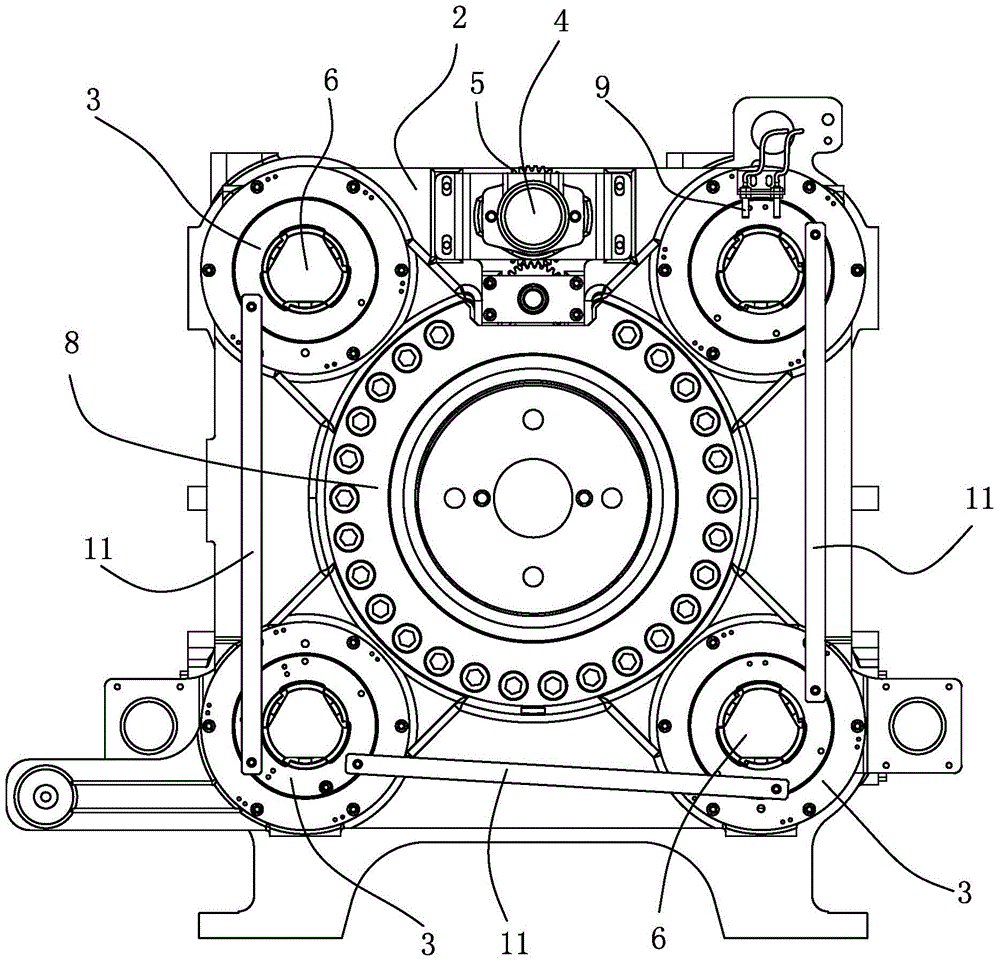

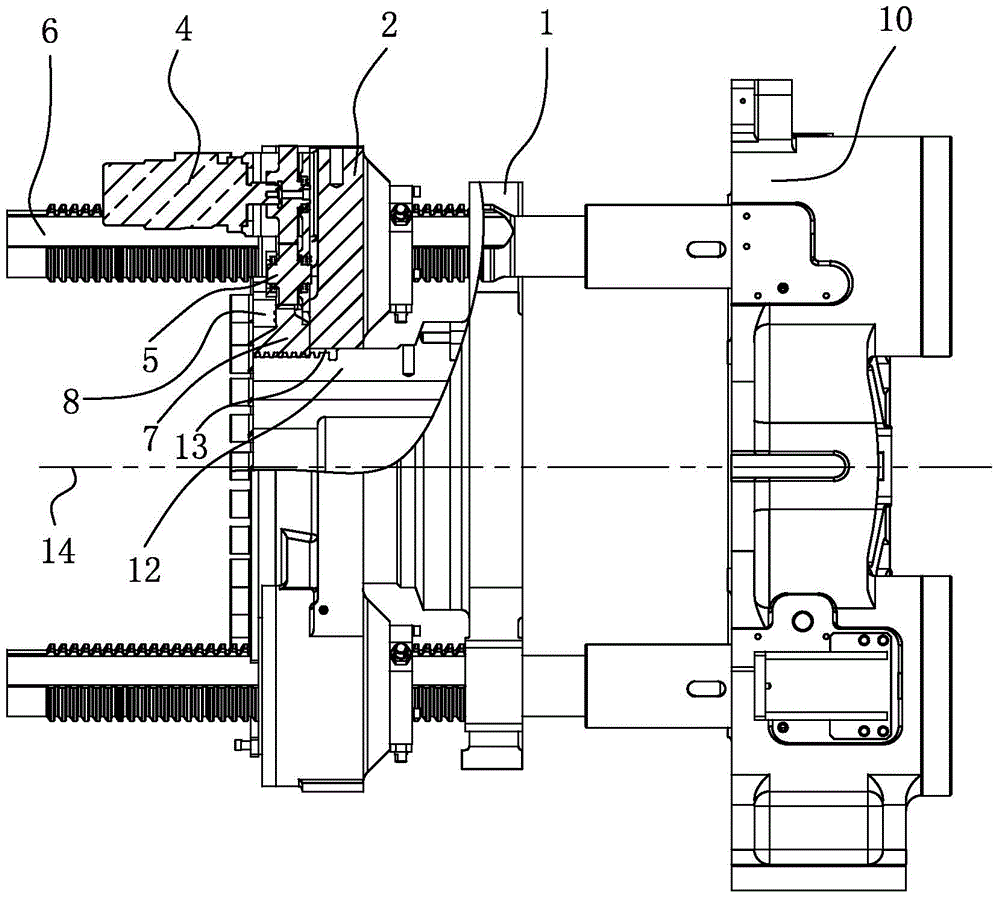

[0026] see Figure 1 to Figure 4 The two-platen injection molding machine of the present invention and its clamping structure include: a certain template 10, a front movable template 1, a rear movable template 2, four gate nuts 3, a transmission power device 4, a transmission gear set 5, four A pull rod 6, an adjusting member 7, a fixed gland 8, a sensor 9, three linkage rods 11, a connecting block 12 and a controller (not shown). The present invention takes the position of the fixed template 10 as the front (that is, with image 3 The position on the right side of the center is the front), and the position of the rear template 2 is the back (that is, the position is based on image 3 Middle left position is back).

[0027] Wherein, the front moving template 1 has a central axis 14 . The rear moving template 2 has a central co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com